Method for fastening member with high strength and low riveting force and 10.9-level short-tail pulling rivet

A high-strength, pull-rivet technology, applied in rivets and other directions, can solve the problems of complex riveting and riveting devices, riveting impact force and noise, and achieve the effects of stable processing, improved fastening performance, and convenient installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for fastening components with high strength and low riveting force in this embodiment consists of the following steps:

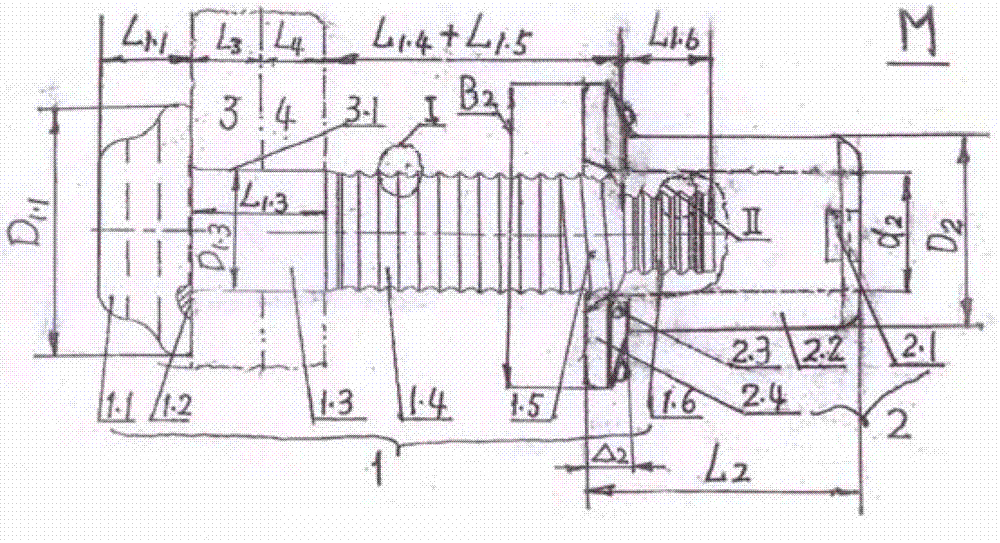

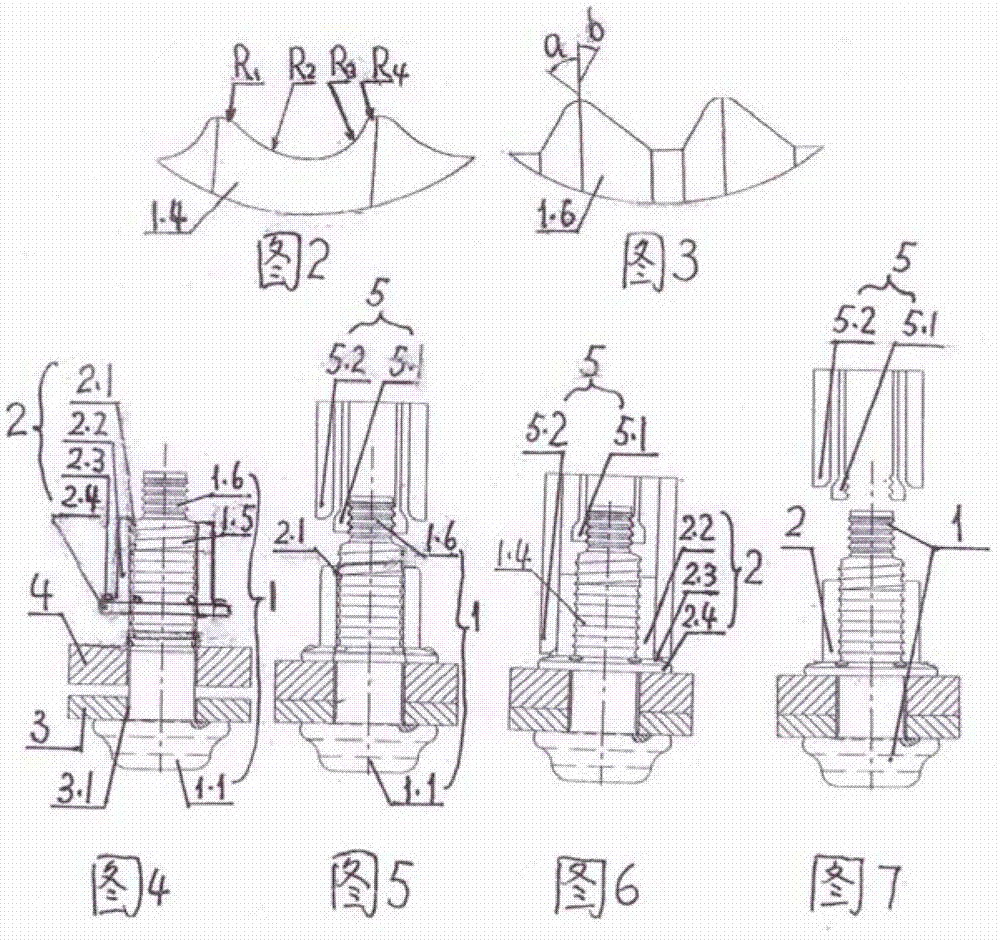

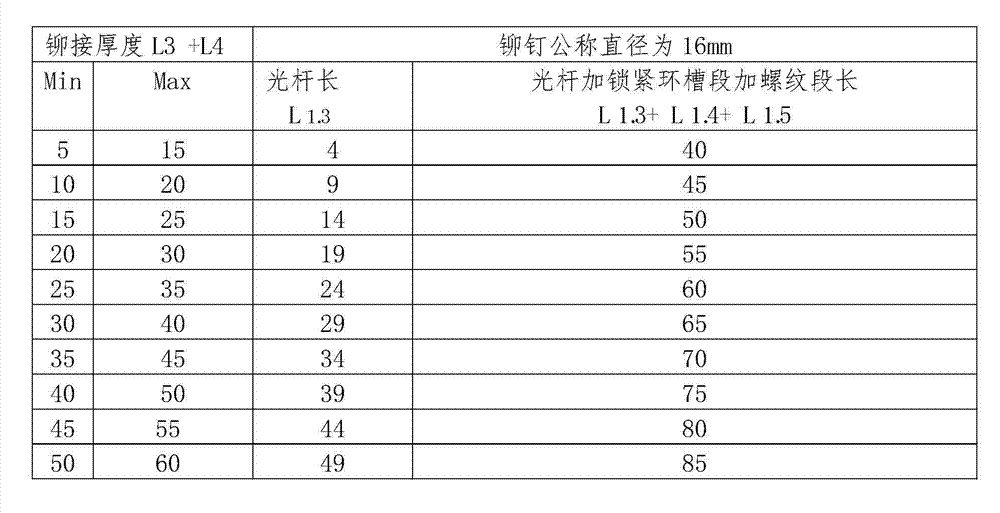

[0022] Step 1: see figure 1 , make the following ⒑9 short-tail rivets M: ① Short-tail rivets M are composed of rivets 1 and collars 2. ② Rivet 1 is composed of nail head ⒈1 connected in sequence from the front end to the rear end, unloading groove ⒈2 opened at the root of the rear end of the nail head ⒈2, polished rod ⒈3, locking ring groove section ⒈4 for extrusion fit with the collar The threaded section ⒈5 which is clamped by the locking teeth ⒉1 and the thin and short ring groove section 16 at the tail which is used for clamping the inner sleeve jaw of the low riveting force hydraulic riveter 5. ③ see figure 2 , Locking ring groove section ⒈4 The curved surface radii from front to back in each ring groove are R1, R2, R3, R4, wherein R1>R4, R2>R3. ④Short ring groove section ⒈6 The angle between the front slope and the radial section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com