Absorption tower of multi-furnace one-tower desulfurizer

A technology of desulfurization device and absorption tower, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high cost, deviation from the designed high-efficiency area, and high energy consumption in low-load operation, and achieves simple structure and easy implementation. Low cost and reduced operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

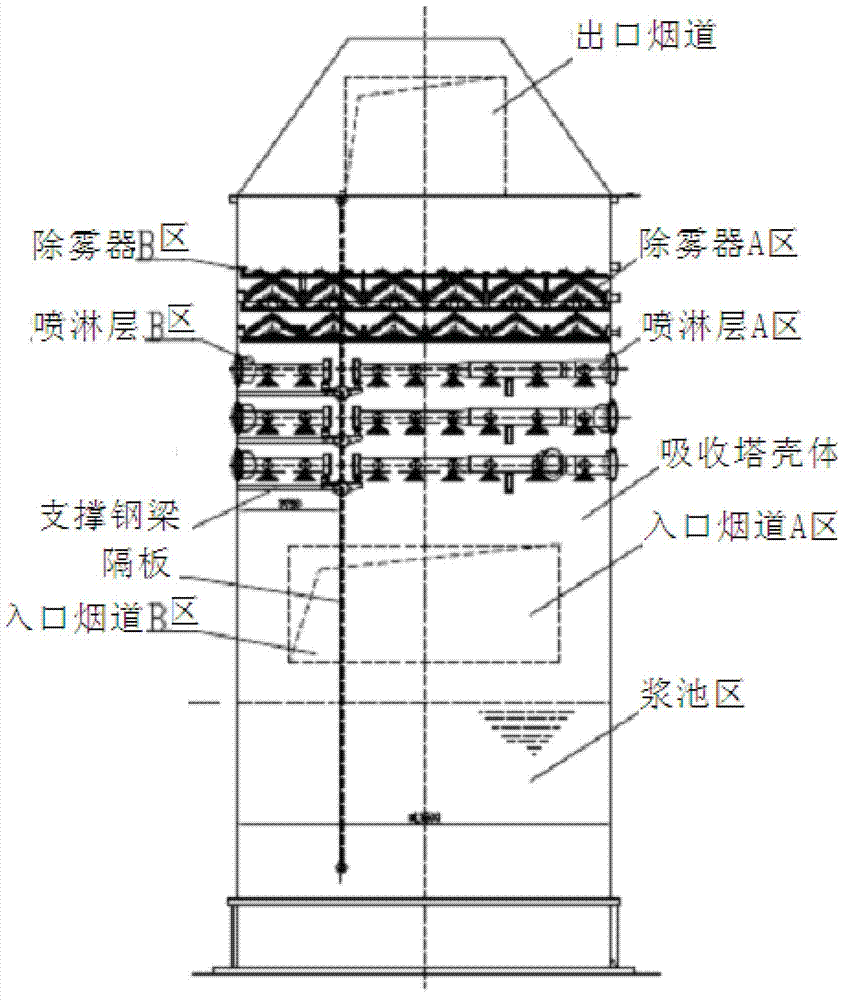

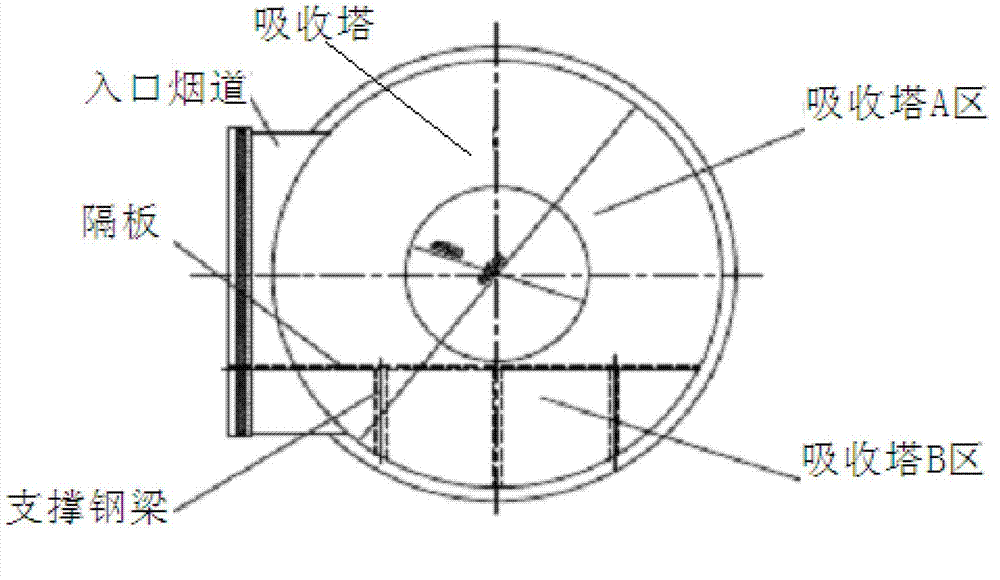

[0026] Such as figure 1 with figure 2 The shown absorption tower of a multi-furnace one-tower desulfurization device includes an absorption tower shell and a slurry pool area, an inlet flue, a spray layer, and a mist eliminator arranged from bottom to top in the absorption tower shell. The absorption tower shell is provided with at least one partition; the partition penetrates the inlet flue, the spray layer and the internal area of the absorption tower shell where the demister is located, and all of the partitions The absorption tower is divided into at least two i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com