Sterilizing and disinfecting infiltration machine

A technology of sterilization, disinfection and pressing wheels, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenience, inconvenience in changing disinfectants, affecting the effect of disinfection and cleaning, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

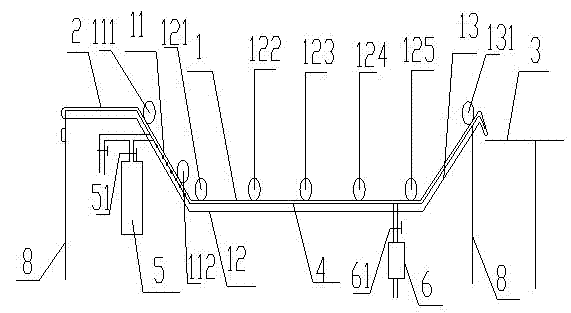

[0013] A sterilization, disinfection and infiltration machine. The sterilization, disinfection and infiltration machine is mainly composed of an infiltration box 1 with a trapezoidal cross section, a finishing preparation table 2, a drying preparation table 3, and equipment arranged under the finishing preparation table 2 and the drying preparation table 3 The legs 8 are used to transport the core products from the finishing rack to the conveyor belt 4 of the drying preparation table. The disinfection reagent preparation box 5 and the waste liquid processor 6 are composed of the lower end of the conveyor belt 4. The infiltration box 1 includes a left side wall 11, The bottom 12 and the right side wall 13 can be heated, and the left side wall 11 is successively provided with a first pressing wheel 111 and a second pressing wheel 112 for temporarily fixing the core products, and the first pressing wheel 111 and the second pressing wheel 112 There is an input port between the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com