Composition for coating

A composition and coating technology, which is applied in the direction of coating, thin material treatment, and devices for coating liquid on the surface, can solve the problems of not considering the properties of the substrate and the requirements of the coating, so as to improve the service life and expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

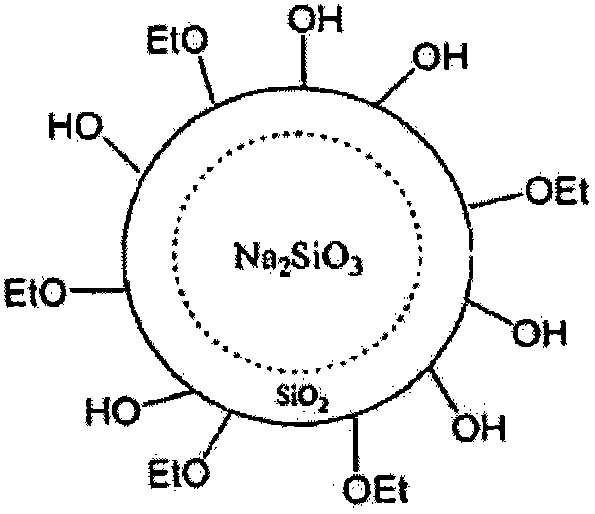

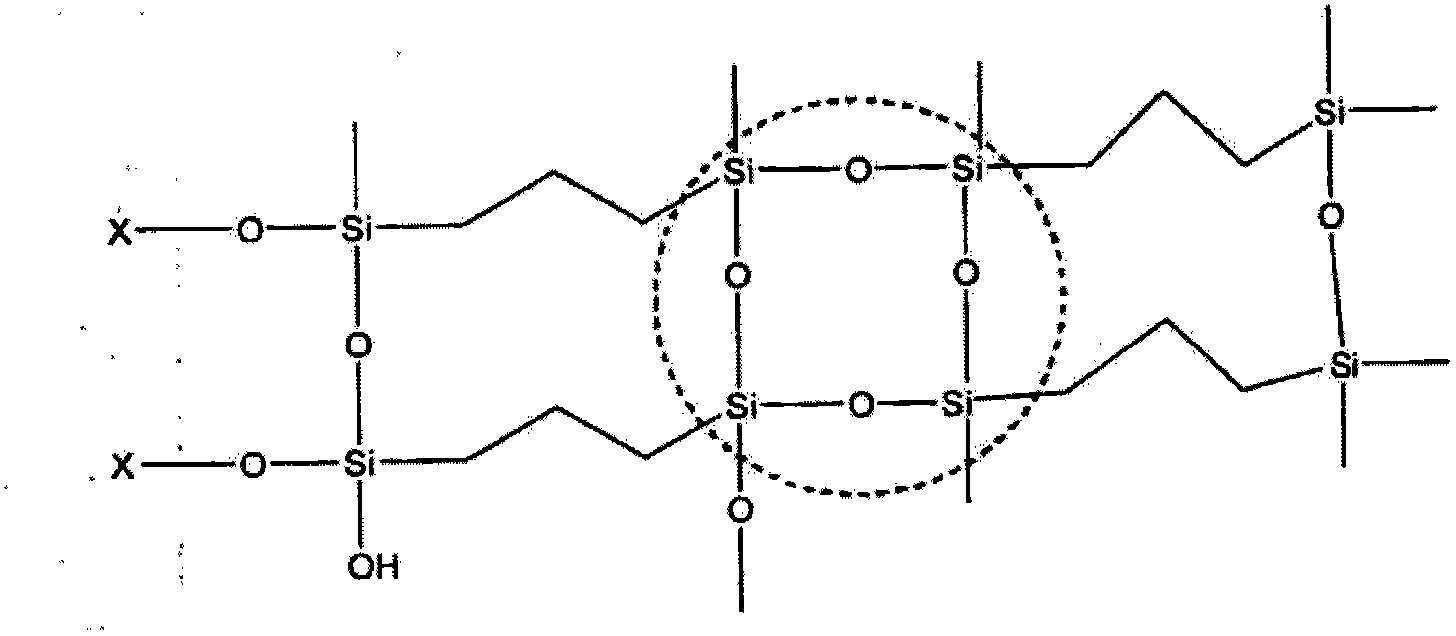

Method used

Image

Examples

Embodiment 1

[0088] Add 1ml of hydrochloric acid to ethanol / water (80ml of ethanol; 20ml of water) hydroalcoholic solution under magnetic stirring, add 55ml of TEOS (tetraethyl orthosilicate) and 23ml of GLYMO (3-glycidyloxypropyl trimethyl Oxysilane). The solution was continuously stirred for 10 minutes, and 5.4 g of α-silicon carbide with a particle diameter of 80 nm was added. The mixture was stirred continuously for 5 minutes before being applied to the surface of the artificial marble slab.

[0089] Dry in an oven at 120°C for 25 minutes.

Embodiment 2

[0091] Add 1ml of hydrochloric acid to ethanol / water (80ml ethanol; 20ml water) hydroalcoholic solution under magnetic stirring, add 40ml of TEOS (tetraethyl orthosilicate) and 40ml of GLYMO (3-glycidyloxypropyl trimethoxy base silane). The solution was continuously stirred for 10 minutes, and 5.4 g of α-silicon carbide with a particle diameter of 1 μm was added. The mixture was stirred continuously for 5 minutes before being applied to the surface of the artificial marble slab.

[0092] Dry in an oven at 85°C for 45 minutes.

Embodiment 3

[0094] The artificial marble slab (substrate) was treated in a 3.5% by volume HCl aqueous solution at 25°C for 40 seconds. The base was washed 3 times with water and then dried.

[0095] Add 1ml of hydrochloric acid to ethanol / water (80ml ethanol; 20ml water) hydroalcoholic solution under magnetic stirring, add 25ml of TEOS (tetraethyl orthosilicate) and 55ml of GLYMO (3-glycidyloxypropyl trimethoxy base silane). The solution was continuously stirred for 10 minutes, and 4.4 g of α-silicon carbide with a particle diameter of 1 μm and 1 g of α-silicon carbide with a particle diameter of 80 nm were added. The mixture was stirred continuously for 5 minutes and applied to the substrate.

[0096] Dry in an oven at 85°C for 45 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com