Full-automatic inspection production line for circular parts

A fully automatic, production line technology, applied in measuring devices, instruments, weighing and other directions, can solve the problems of low labor efficiency, a large number of labor and man-hours, and high product costs, and achieve the effect of high degree of automation and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

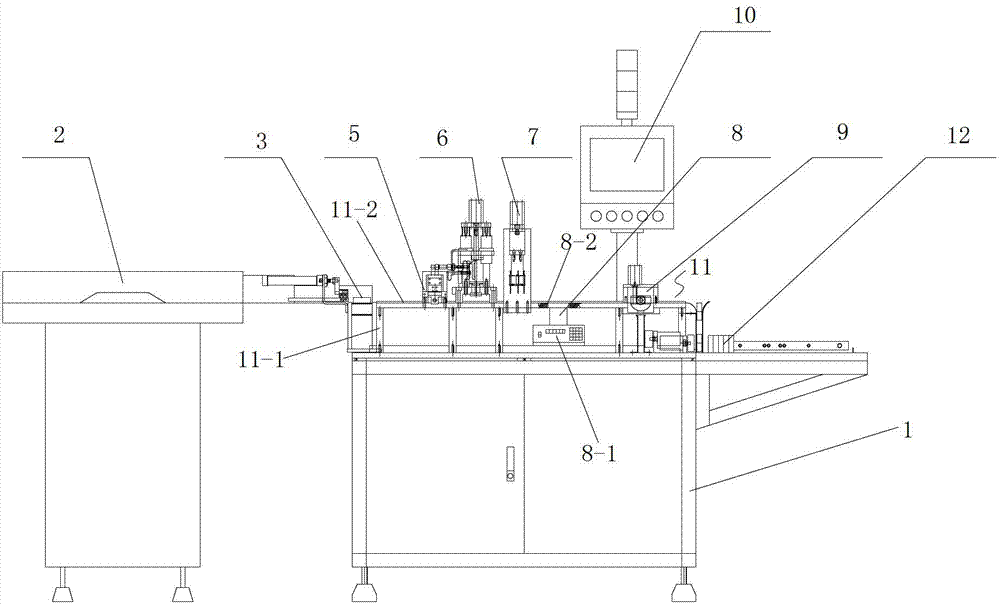

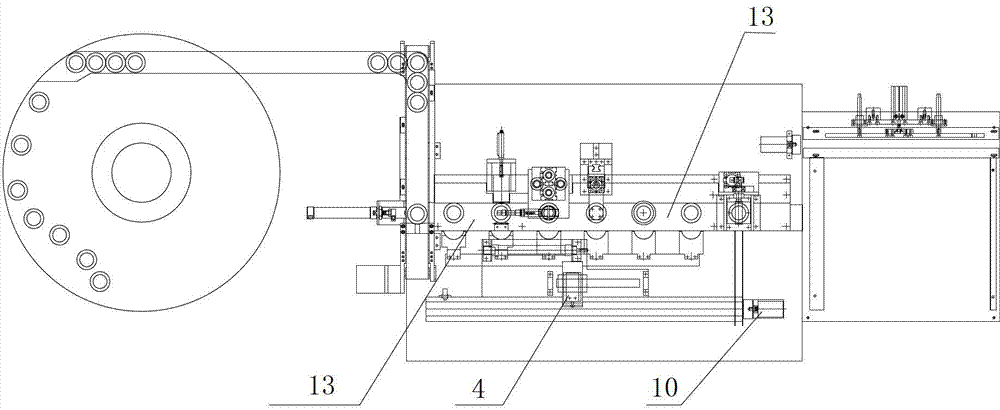

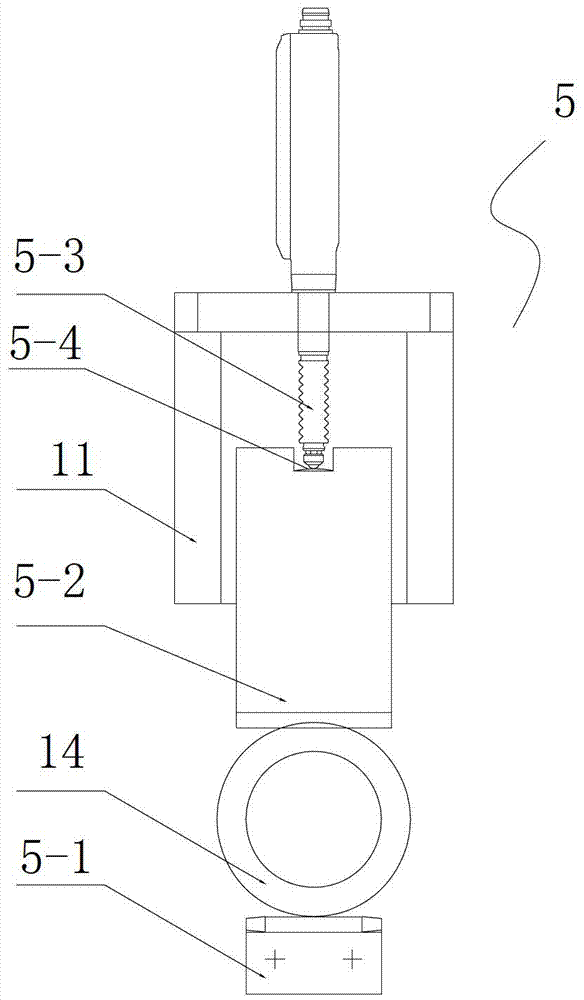

[0024] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a fully automatic inspection production line for circular parts, including a bed 1, a disc-type electromagnetic oscillation feeding device 2 , feeding conveyor belt device 3, workpiece moving mechanism 4, outer diameter detection mechanism 5, inner diameter detection mechanism 6, thickness detection mechanism 7, weight detection mechanism 8, screening mechanism 9 and touch display fixedly connected to the bed Screen 10, the disc-type electromagnetic oscillation feeding device is placed at the left end of the bed, the outlet of the disc-type electromagnetic oscillation feeding device is connected to the feeding conveyor belt device, and the outlet of the feeding conveyor belt device is connected to the workbench fixed on the upper surface of the bed For docking, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com