Gear interlocking device of five-gear manual transmission

A technology of manual transmission and interlocking device, which is applied in the direction of transmission device control, mechanical control device, instrument, etc., can solve the problems of multi-speed transmission space layout design restrictions, danger, transmission damage, etc., and achieve easy layout design and reliable interlocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

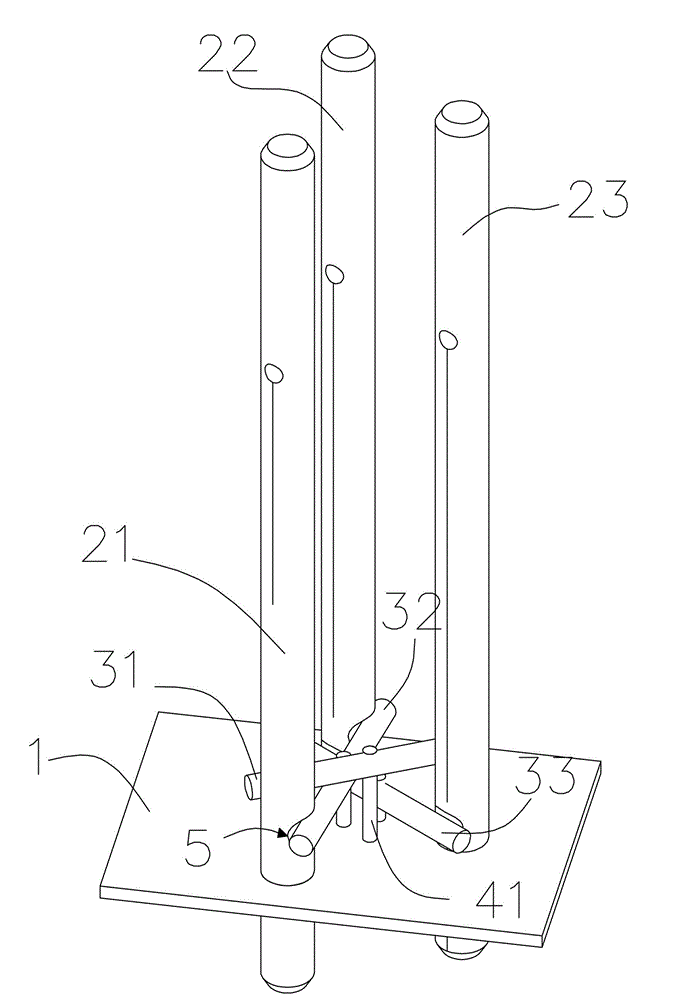

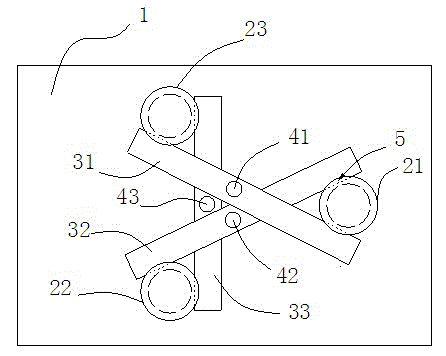

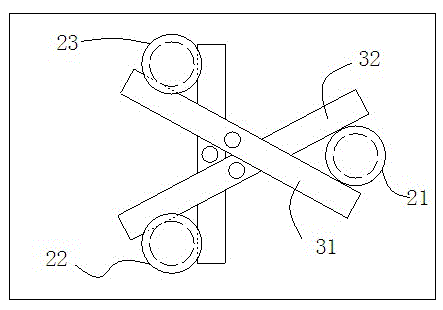

[0017] This embodiment relates to a gear interlocking device for a five-speed manual transmission, which consists of figure 1 , figure 2 As shown, it includes three shift fork shafts arranged in parallel on the transmission case 1, wherein, figure 1 The schematic structure of the transmission case 1 is shown in , which is mainly convenient to show the connection and positional relationship of other components with it; and based on the three shift fork shafts in the five-speed manual transmission, in this embodiment, all of them adopt the existing transmission The setting in, that is, the three shift fork shafts are respectively the fifth reverse gear shift fork shaft 21, the third and fourth gear shift fork shafts 22 and the first and second gear shift fork shafts 23, and each shift fork shaft is connected and arranged on the On the transmission case 1, and can move axially relative to the transmission case 1, three shift fork shafts are arranged in a triangle in the space. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com