Automatic arranging machine for disc type transformer skeleton

A technology of transformer skeleton and automatic arrangement, which is applied in the stacking, transportation and packaging of objects, can solve the problems of incompatibility with mechanized production and high labor intensity, and achieve the effect of avoiding manual labor and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

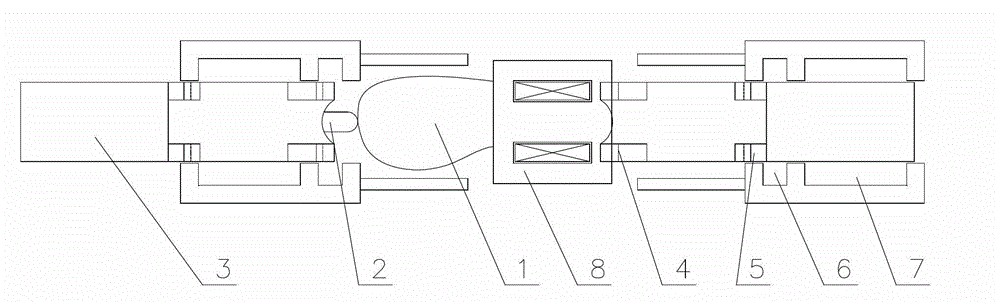

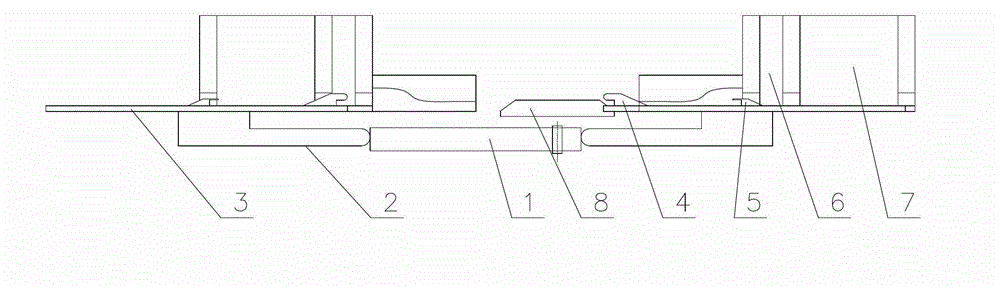

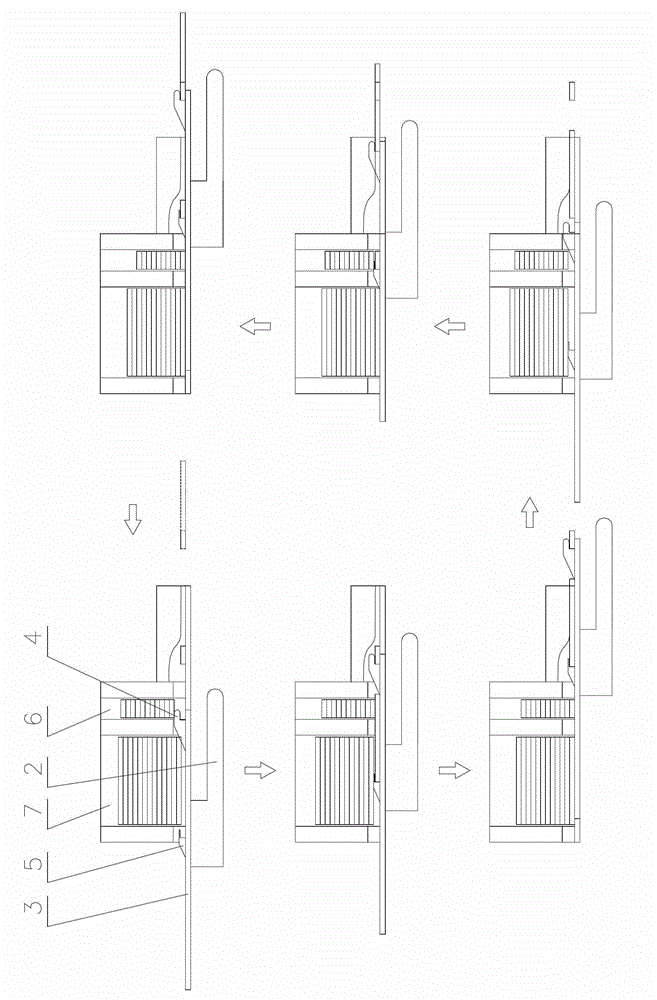

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 , figure 2 Shown is an automatic arrangement machine for disc-type transformer skeletons, including a frame, a cam 1, a stacking platform 8 and two sets of driven mechanisms with identical structures and opposite positions. Put slot, push plate 3 and the push rod 2 that is compatible with cam 1, the housing of described stacking platform 8, two magnetic sheet containers, the motor that drives cam 1 rotations is all fixed on the frame, pre-put slot and The magnetic sheet container is fixed and is located between the magnetic sheet container and the stacking platform 8, and the stacking platform 8 is provided with a clamp for placing two cylindrical magnetic cores; one end of the push rod 2 is fixed with the push plate 3, and the other end is connected with the cam 1 contact, drive the two push plates 3 to move in a straight line, and the stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com