Handcart

A trolley and handle technology, applied in the field of trolleys, can solve problems such as increased labor intensity, poor sanitation environment, and reduced work efficiency, and achieve the effects of reducing labor intensity, reducing hygiene problems, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

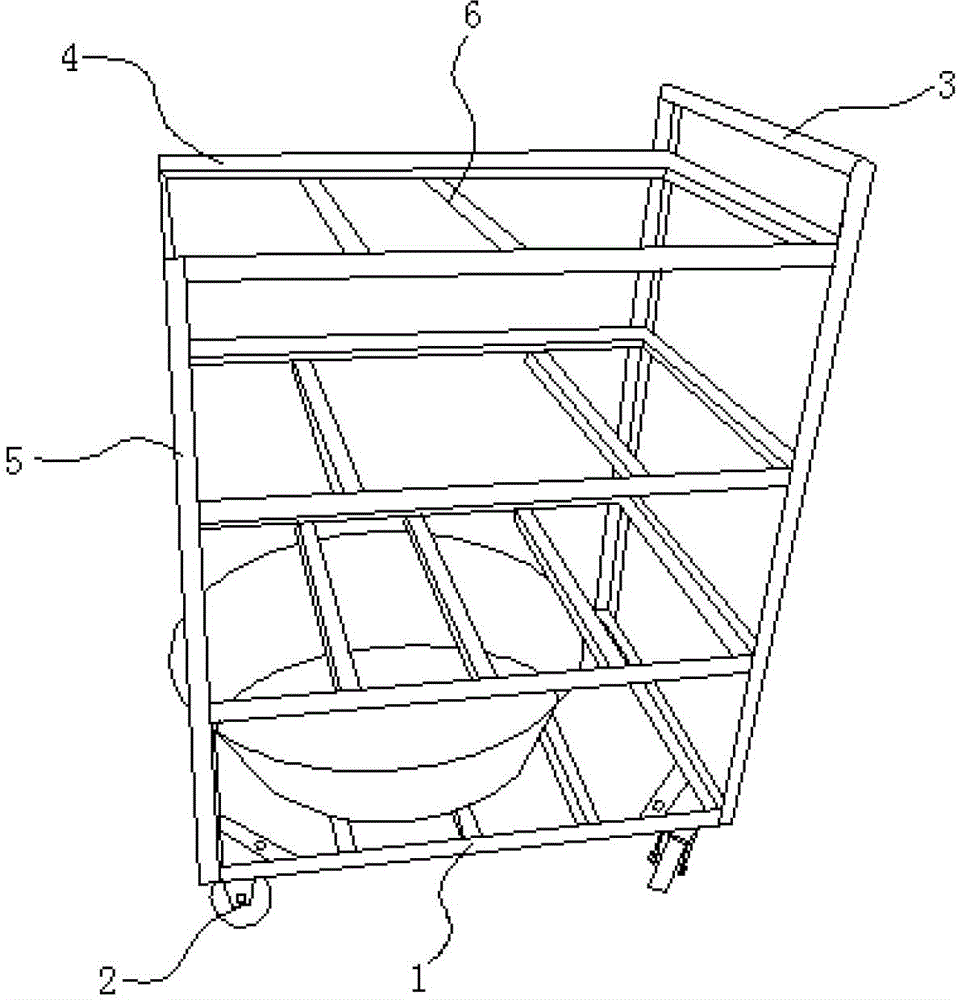

[0016] Embodiment one: see figure 1 As shown, a trolley includes a bottom frame 1, a universal wheel 2 installed under the bottom frame 1, a handle 3 connected to the rear end of the bottom frame 1, and four layers of materials are stacked above the bottom frame 1 Pan frame 4, the rear end of the material pan frame 4 is fixedly connected with the handle 3, the front end of the material pan frame 4 is connected with the front end of the bottom frame 1 respectively through two columns 5, the material At least two cross bars 6 are arranged between the tray 5 and the bottom frame 1 to form a frame structure with 3 to 6 unit spaces. The height of the material tray 4 on the top layer matches the height of the handle 3 .

[0017] In the process of material handling, first place different types of materials on the 4-layer material tray frame 4 above the bottom frame 1, and then push the handle 3 connected with the bottom frame 1 and the rear end of the material tray frame 4, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com