Pneumatic particle size classifying device for solid particles

A solid particle and classification device technology, applied in the direction of solid separation, separation of solids from solids with air flow, chemical instruments and methods, etc., can solve the problems of difficult separation process of coking coal and medium, low degree of automation, poor reliability of equipment, etc. , to achieve the effect of lengthening the residence time, increasing the processing capacity and reducing the effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles, specific structures and best embodiments of the present invention will be further described below with reference to the accompanying drawings.

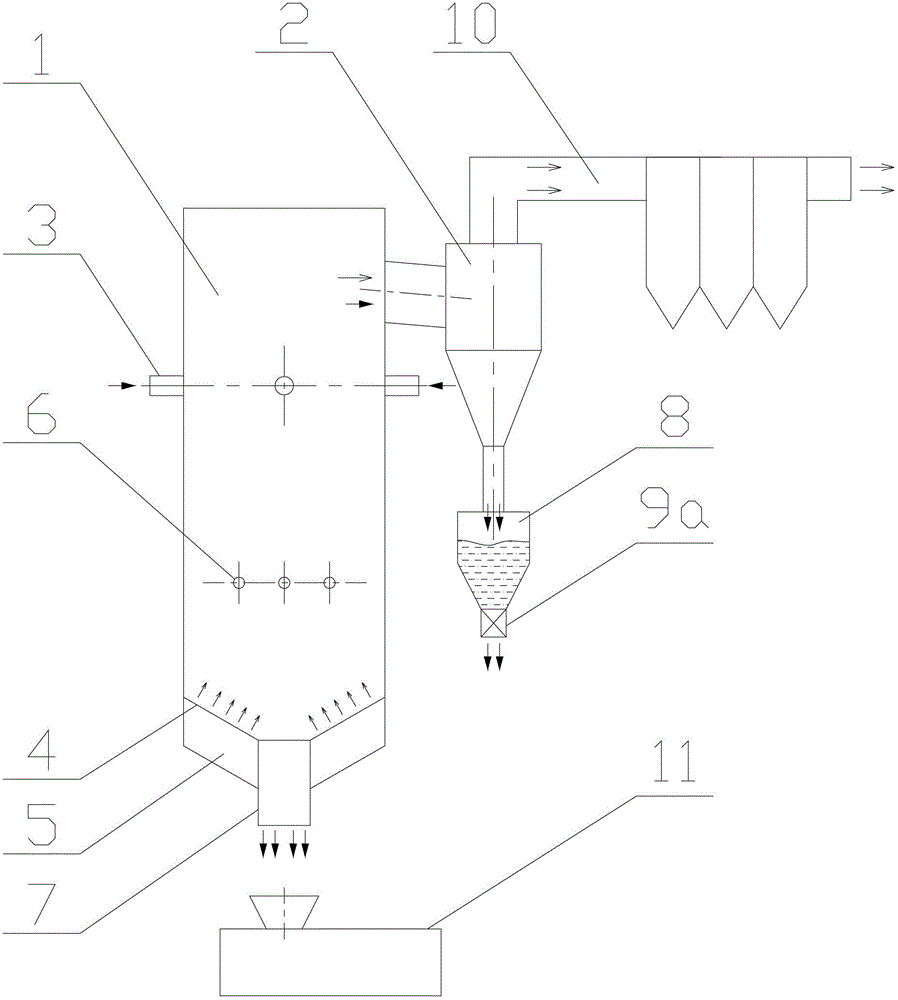

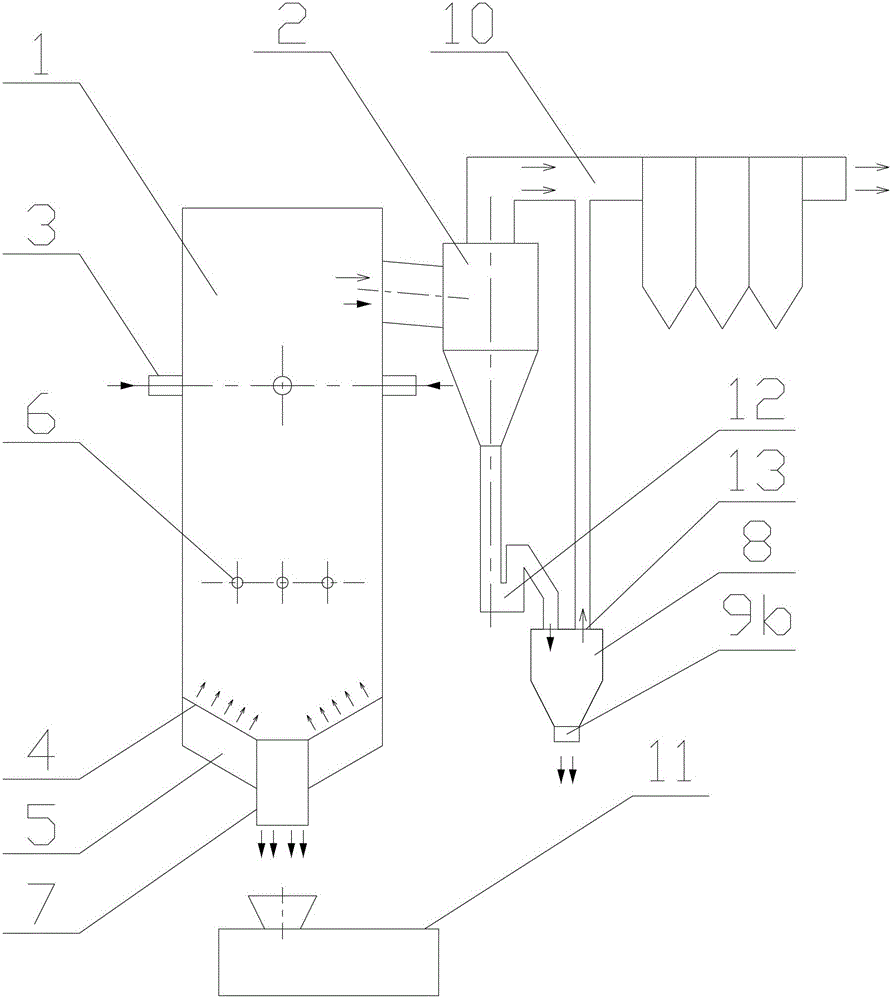

[0014] figure 1 It is a schematic front view of the overall structure of the first embodiment of the present invention. The present invention includes a fluidized bed main body 1, a cyclone separator 2, a feeding port 3, an air distribution system, a secondary air outlet 6, a coarse material outlet 7 and a fine material collection and discharge In the system, the feed port 3 is arranged in the middle and upper part of the main body 1 of the fluidized bed, and the selected materials are fed from the feed port 3. The arrangement position of the feed port 3 mainly considers the residence time of the particles in the fluidized bed, and the position is too low. The particles will be directly discharged from the coarse material outlet without effective sorting, and the feeding port 3 is arranged at multiple points. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com