Whole broad bean flour glass noodles and sheet jelly and production method thereof

A broad bean and whole flour technology, applied in the application, food preparation, food science and other directions, can solve the problems of low nutritional value of fans, and achieve the effects of fine taste, rich nutrition and improved nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, prepare broad bean whole powder vermicelli

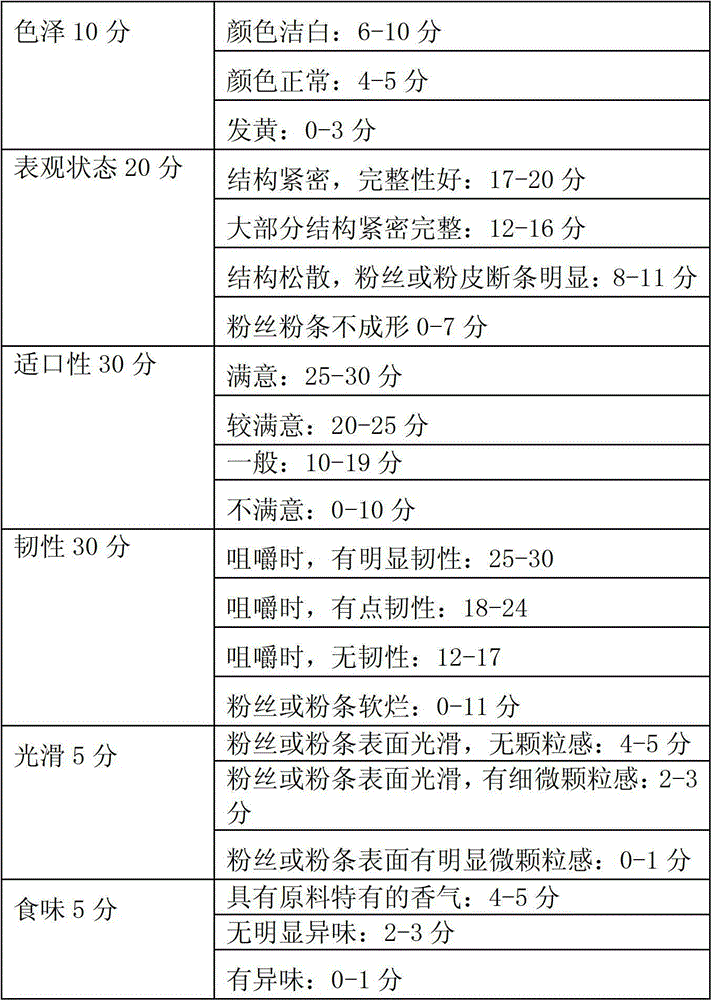

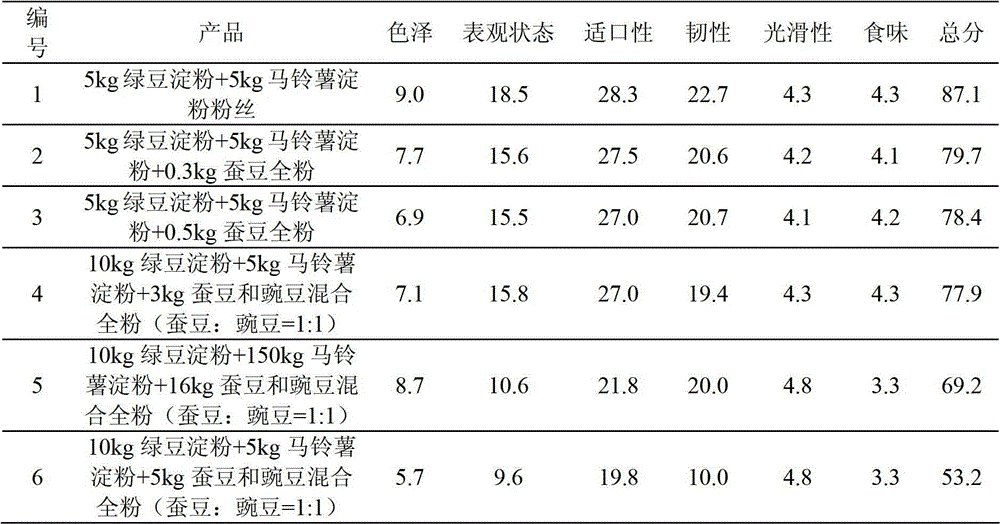

[0019] Broad beans are pulverized by jet crushing and classifying equipment of model JFC-5, sieved to obtain broad bean powder with a particle size less than 50 microns, and set aside; add 0.3kg of ground broad bean powder to 5kg mung bean starch and 5kg potato starch, and then Add 1.5kg of warm water at about 60°C and stir evenly, then pour the mixed starch into the powder leaker, pass through the drainer (the diameter of the eye of the drainer is 0.5cm, and the shape is round) and naturally drop into water at 100°C for 10 seconds and then come out pot, put into tap water to cool down to about 10°C, then freeze at -8°C for 6 hours, and after thawing, dry the product at 50°C to obtain instant vermicelli containing broad bean powder. The sensory evaluation results are shown in Table 2 (No. 2).

[0020] The prepared vermicelli can be eaten directly after brewing with 80°C water for 3 to 10 minutes, and the taste ...

Embodiment 2

[0022] Embodiment 2, prepare broad bean whole powder vermicelli

[0023] The broad beans are crushed by JFC-5 jet crushing and grading equipment, and sieved to obtain broad bean powder with a particle size of less than 50 microns for later use; add 0.5 kg of crushed broad bean powder to 5 kg of mung bean starch and 5 kg of potato starch, and then add 1.5 kg of 80 Warm water at about ℃ is stirred evenly by a mixer, and then the mixed starch is poured into the powder leaker, and it naturally falls through the leaker (the diameter of the eye of the filter is 0.5cm, and the shape is flat) into water at 100°C, boiled for 10 seconds, and then put it out of the pot. Pour into tap water to cool down to about 5°C, then freeze in -14°C for 6 hours, and dry the product at 30°C after thawing to obtain instant vermicelli containing broad bean powder. The sensory evaluation results are shown in Table 2 (No. 3).

[0024] The prepared vermicelli can be eaten directly after brewing with 80°C ...

Embodiment 3

[0025] Embodiment 3, preparation broad bean whole powder vermicelli

[0026] After mixing broad beans and peas in a mass ratio of 1:1, they are crushed by JFC-5 jet crushing and grading equipment, and sieved to obtain broad bean and pea mixed powder with a particle size of less than 50 microns for use; add 10kg mung bean starch and 5kg potato starch Add 3kg of crushed broad bean and pea powder, then add 3kg of warm water at about 60°C and stir evenly with a mixer, then pour the mixed starch into the powder drainer and pass through the drainer (the diameter of the eye of the drainer is 0.5cm, and the shape is flat) Drop naturally into 100°C water and cook for 10 seconds, then take out of the pot, put in tap water to cool down to about 10°C, then freeze at -8°C for 6 hours, after thawing, dry the product at 50°C to obtain broad bean powder And instant vermicelli with pea flour. The sensory evaluation results are shown in Table 2 (No. 4).

[0027] The prepared vermicelli can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com