Method for processing green tea in summer and autumn without bitterness by utilizing fresh tea leaves in summer and autumn

A technology of fresh leaves and bitter taste of tea, applied in the field of production and processing of summer and autumn green tea without bitterness and astringency, can solve the problems of waste of fresh leaf resources, summer and autumn tea without a consumer market, and bitter taste of summer and autumn green tea, and achieve economical high-value utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

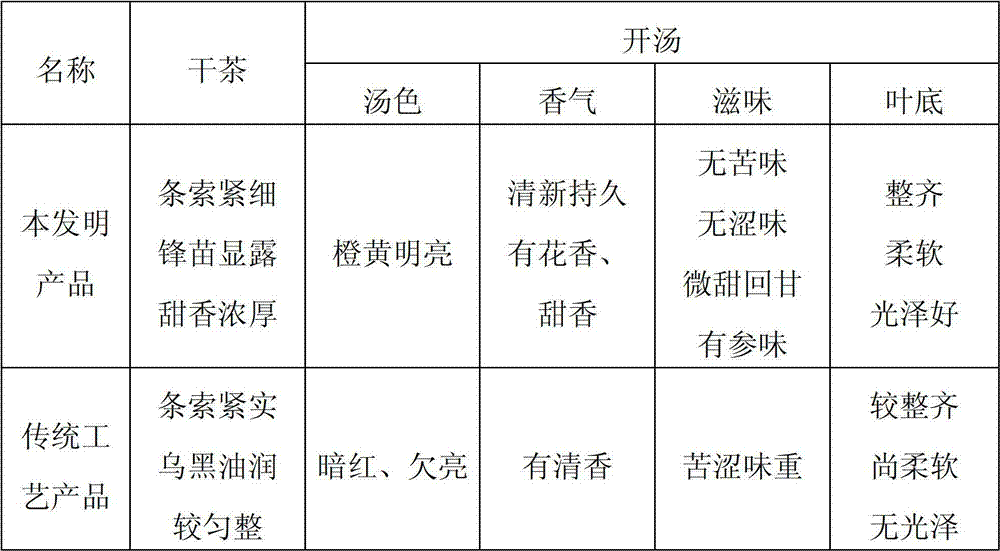

Examples

Embodiment 1

[0032] Choose fresh tea leaves with one bud and two leaves in summer from Fuyun No.6, an excellent tea tree variety.

[0033] The summer one-bud and two-leaf tea leaves of the improved tea tree variety Fuyun No. 6 were spread for 20 hours at a relative humidity of 85% and an ambient temperature of 25°C, using a roller curing machine at an inlet temperature of 140°C and an outlet temperature of 90°C. Chill for 2 minutes and cool to room temperature; mix Gynostemma pentaphyllum extract with 80% gypenoside content, licorice extract, and stevioside extract with 90% stevioside content in a weight ratio of 1:2:2, and then press 1kg Add 40 grams of the mixture of the above extracts to the chilled leaves after cooling, mix the two evenly, and use a tea kneading machine to knead the leaves until the stripping rate reaches 95% and the cell damage rate reaches 85%. Shake the sieve machine for 2 times; then use a tea dryer at 110°C for the initial drying, until the hand is clumped into a mas...

Embodiment 2

[0035] Choose the fresh leaves of one-bud three-leaf tea in autumn as the raw material.

[0036] After spreading the fresh leaves of one bud and three leaves autumn tea of tea plant populations at a relative humidity of 75% and an ambient temperature of 20°C for 12.5 hours, they were cured with a roller curing machine at an inlet temperature of 110°C and an outlet temperature of 70°C for 1 min, and then cooled to Room temperature; mix Gynostemma pentaphyllum extract with 60% gypenoside content, licorice extract, and stevioside extract with 60% stevioside content in a weight ratio of 1:2:2, and then add 1kg of chilled leaves after cooling The ratio of 25 grams of the above extract mixture, mix the two evenly, use a tea kneading machine to knead until the leaf formation rate reaches 75% and the cell damage rate reaches 65%, and then use a three-mesh shaker to deblock 1 Second; the first kneaded leaves are initially dried at 90°C with a tea dryer, until the hands are clumped into ...

Embodiment 3

[0038] Choose fresh tea leaves with one bud and one leaf in autumn as raw materials.

[0039] After the autumn one bud and one leaf tea leaves of the tea plant population are spread for 16 hours at a relative humidity of 80% and an ambient temperature of 22°C, they are cured with a roller curing machine at an inlet temperature of 125°C and an outlet temperature of 80°C for 1.5 minutes, and then cooled to Room temperature; mix Gynostemma pentaphyllum extract with 70% gypenoside content, licorice extract, and stevioside extract with 75% stevioside content in a weight ratio of 1:2:2, and then add 1kg of chilled leaves after cooling The ratio of the mixture of 30 grams of the above-mentioned extracts, mix the two evenly, use a tea kneading machine to knead until the leaf formation rate reaches 85% and the cell damage rate reaches 75%, and then use a three-mesh shaker to deblock 1 Second; the first kneaded leaves are initially dried at 100℃ with a tea dryer, until the hands are clumpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com