Shift securing device for a multi-speed manual gearbox

A multi-speed transmission and stop device technology, which is applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of unsuitable transmissions and rare transmission structures, so as to save space and avoid stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

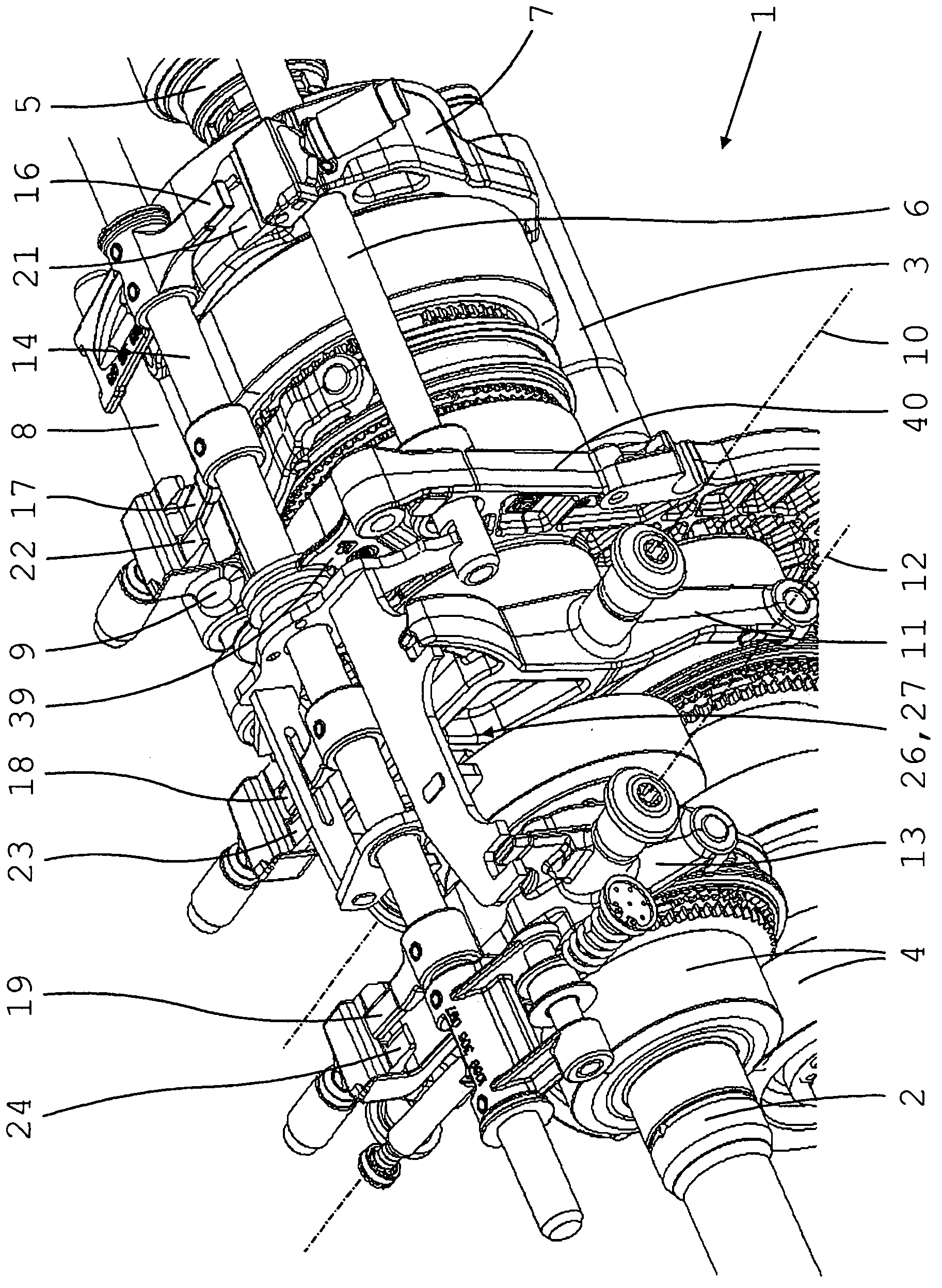

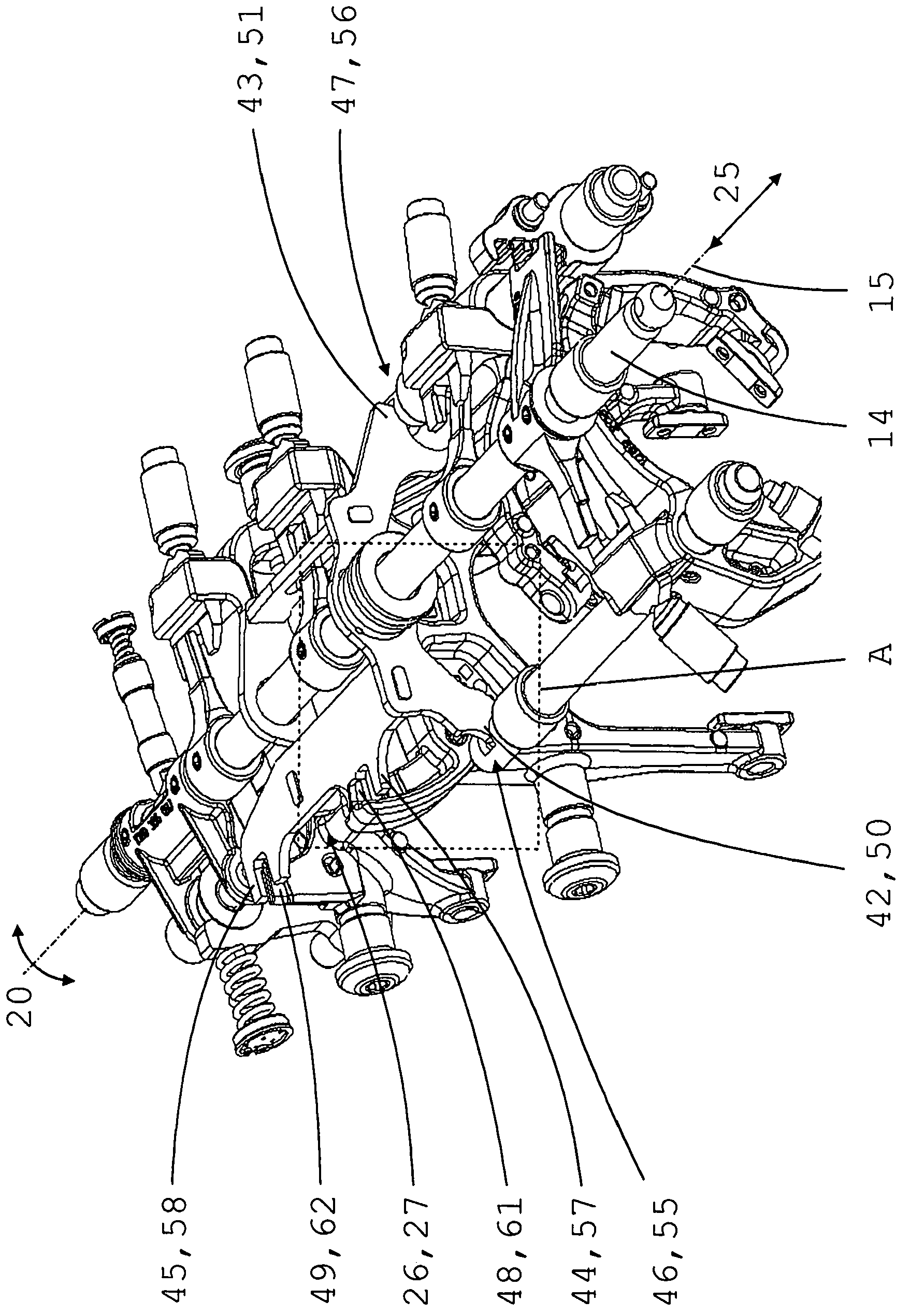

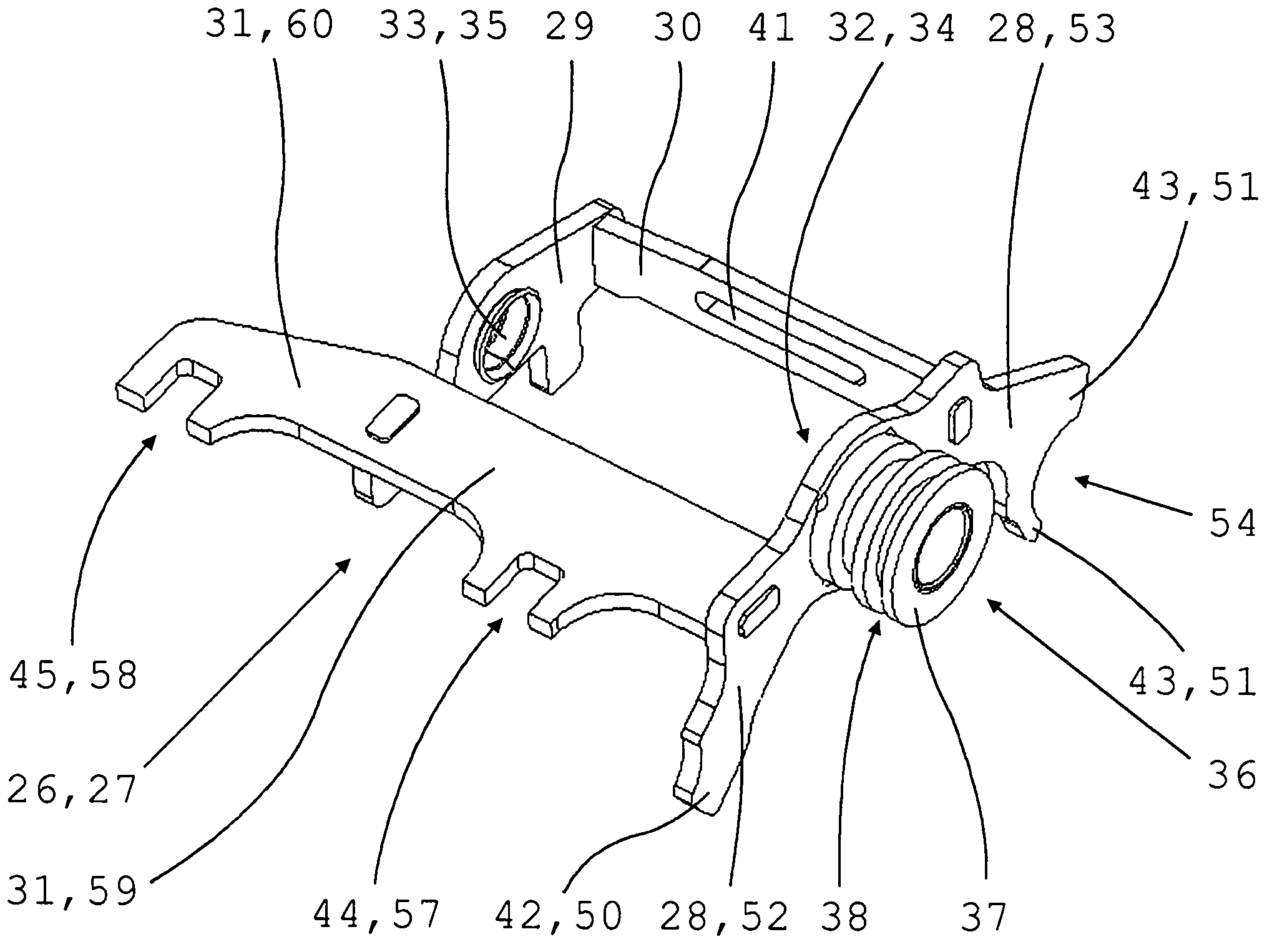

[0033] exist figure 1 with 2 The transmission 1, which is only partly shown in the figure, is designed as a layshaft structure and comprises an input shaft 2, a layshaft 3 arranged axially parallel to the input shaft, and an output shaft 5 arranged coaxially adjacent to the input shaft 2 , the countershaft is drivingly connected to the input shaft 2 via an input constant 4 configured as a pair of spur gears.

[0034] The transmission 1 has a total of seven switchable gears, that is, six forward gears G1 to G6 and one reverse gear R, wherein each of the six gears consists of a gear arranged between the layshaft 3 and the output shaft 5, each with a The fixed gear and a spur gear set with an idler gear that can be connected to the corresponding drive shaft 3, 5 via a gear clutch, and a high forward gear (G5 or G6) is configured as a drive shaft through the input shaft 2 and the output shaft 5 Direct connection to direct gear that can be switched on. The gear clutch of the rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com