Device for densely loading a divided solid into a chamber

A dense and solid technology, applied in the direction of loading/unloading, transportation and packaging, chemical instruments and methods, etc., can solve the problems of irregular temperature profile, reduced conversion effect, accelerated breakdown of catalytic bed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

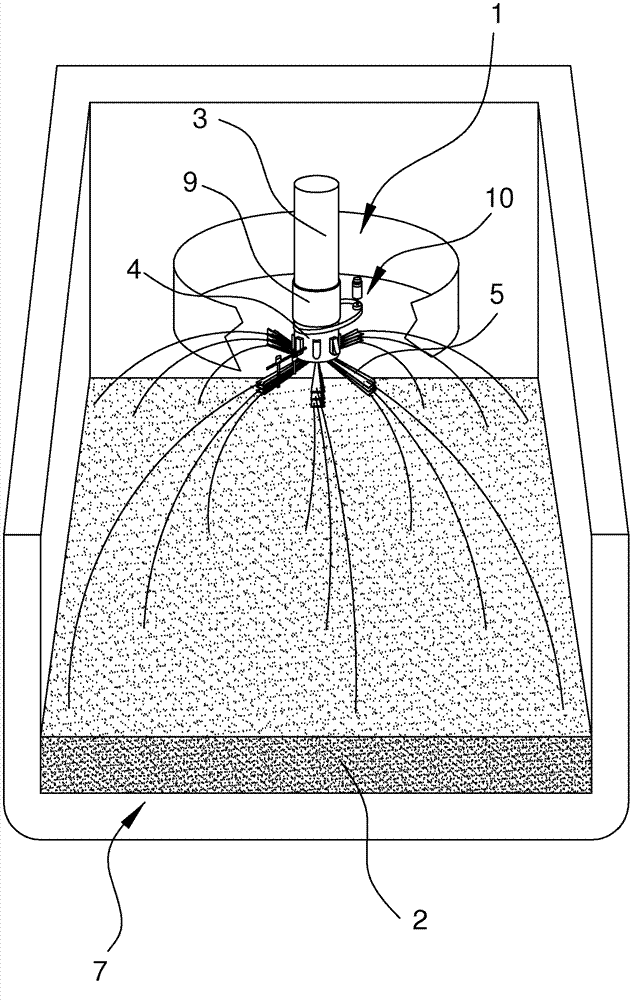

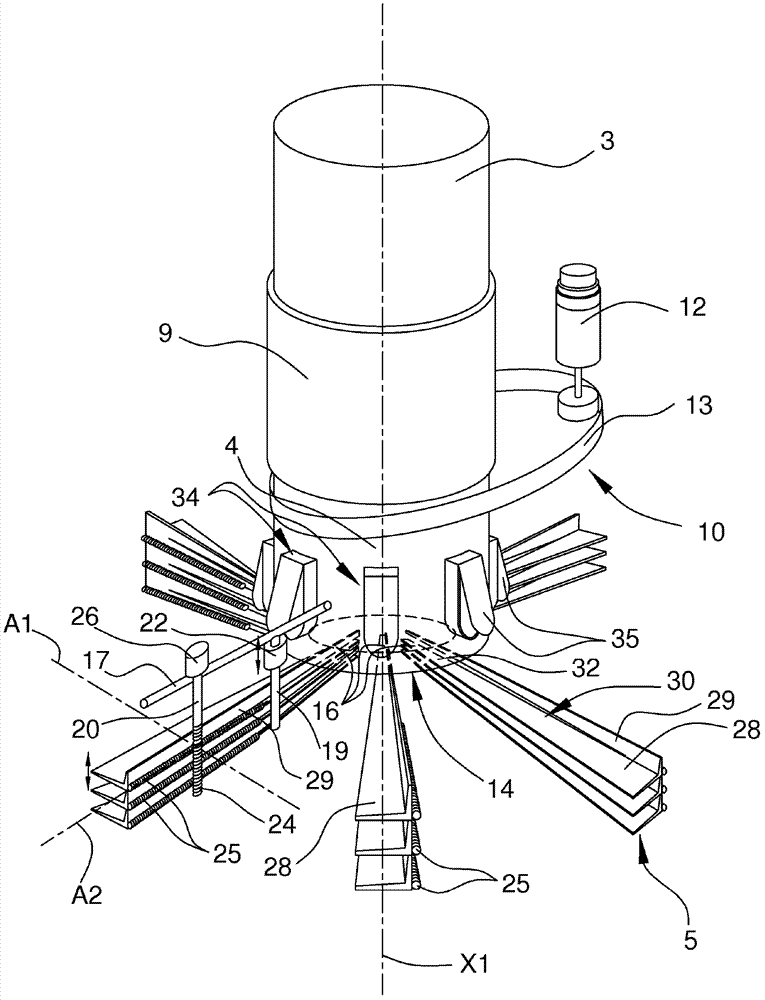

[0033] figure 1 The principle of operation of the dense loading device according to the invention is shown in a non-limiting and schematic manner.

[0034] The dense loading device 1 is supplied with grain pellets 2 : from the initial storage location, usually at a fixed flow rate, via tubes to the trough 3 . It is not beyond the scope of the present invention that conventional surge funnels could be designed to be used between the barrel and the trough.

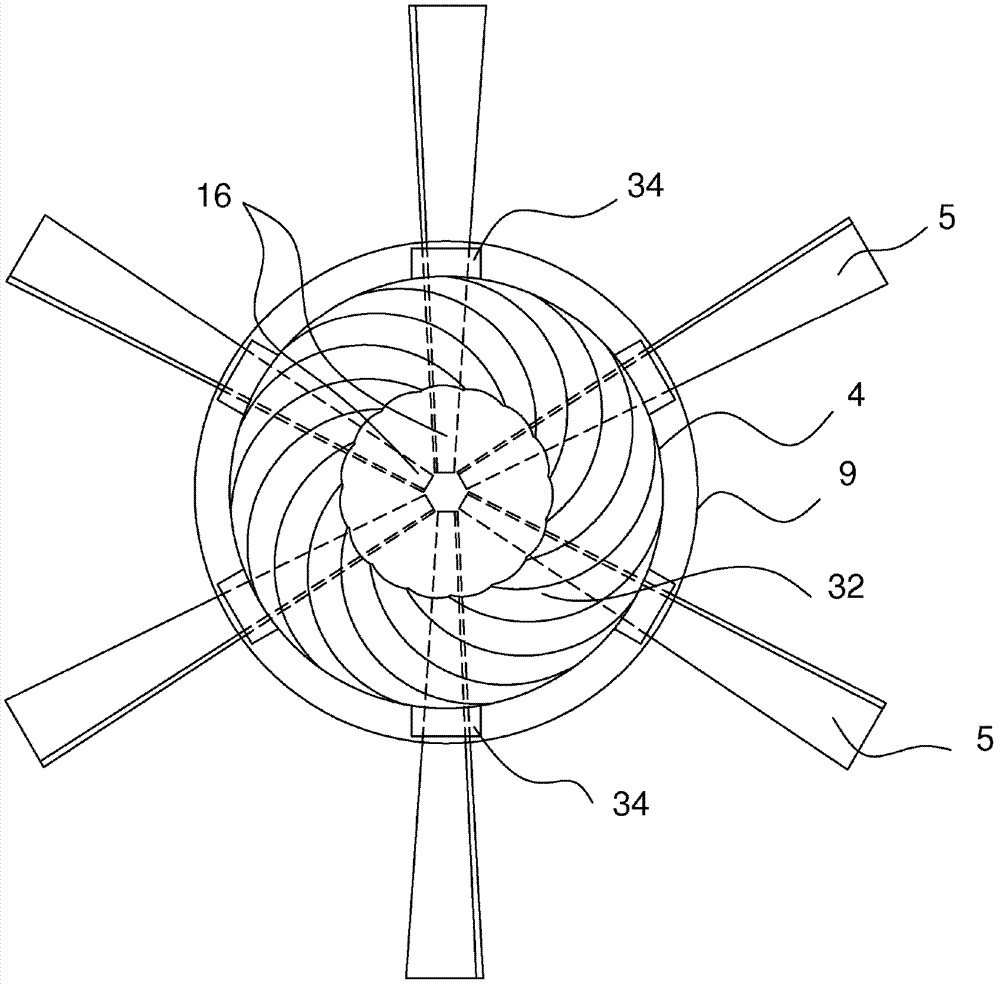

[0035] The loading device 1 arranged in alignment with the trough 3 includes a rotating mechanism 4 for loading particles from the tube, and has a plurality of openings for evenly distributing the particles on the entire set of flow guide elements 5 (to be used with figure 2 are described in more detail together).

[0036] Preferably, the particle jet should be split as much as possible in order to optimize the distribution of the particles before it is loaded by the flow guiding element. The particles thus fall onto the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com