Texturing component of thin-film solar glass substrate texturing unit

A thin-film solar and glass substrate technology, applied in electrical components, semiconductor devices, final product manufacturing, etc., can solve the problems of uneven thickness of texturing, inability to realize automatic production, poor etching quality, etc., to improve the etching quality and The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

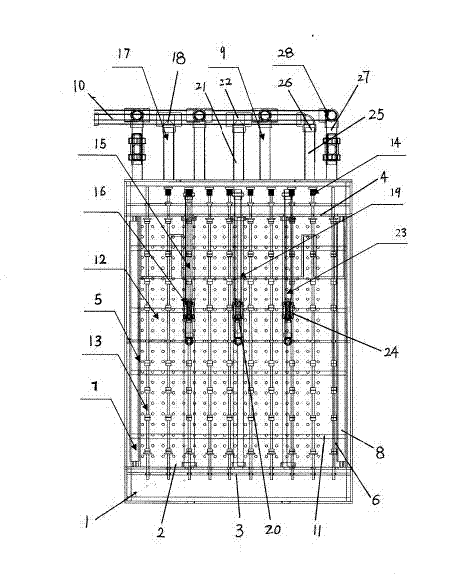

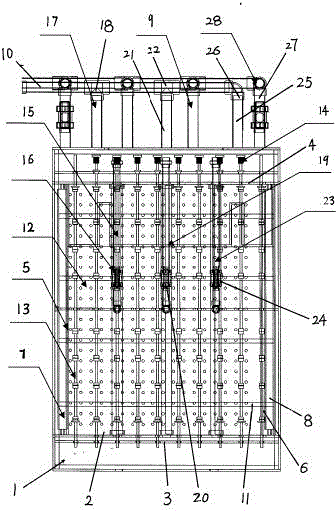

[0011] A texturing component of thin-film solar glass substrate texturing equipment, including a PLC and a rectangular bottom tank 1, an elevated etching tank 2 is nested in the rectangular bottom tank 1, and the outer bottom surface of the etching tank 2 is connected to the rectangular bottom The etchant discharge area is formed between the inner bottom surfaces of the tank 1, and the etching tank 2 is composed of a front baffle 3, a rear baffle 4, a left texturing liquid height adjustment plate 5, a right texturing liquid height adjustment plate 6 and an etching tank. The bottom plate forms a closed etching area, and a skeleton 11 is arranged at the bottom of the etching tank 2, and a water uniform plate 12 is arranged on the skeleton 11, and holes are evenly distributed on the water uniform plate 12, and engraved holes are arranged on the bottom plate of the etching tank. The bottom inlet of the etching solution is connected with one end of the etching liquid inlet pipe 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com