Wheel type polishing machine

A polishing machine and wheel-type technology, which is applied in the preparation of test samples, etc., can solve the problems of compound grinding and other problems, and achieve the effect of smooth transmission, no noise, and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

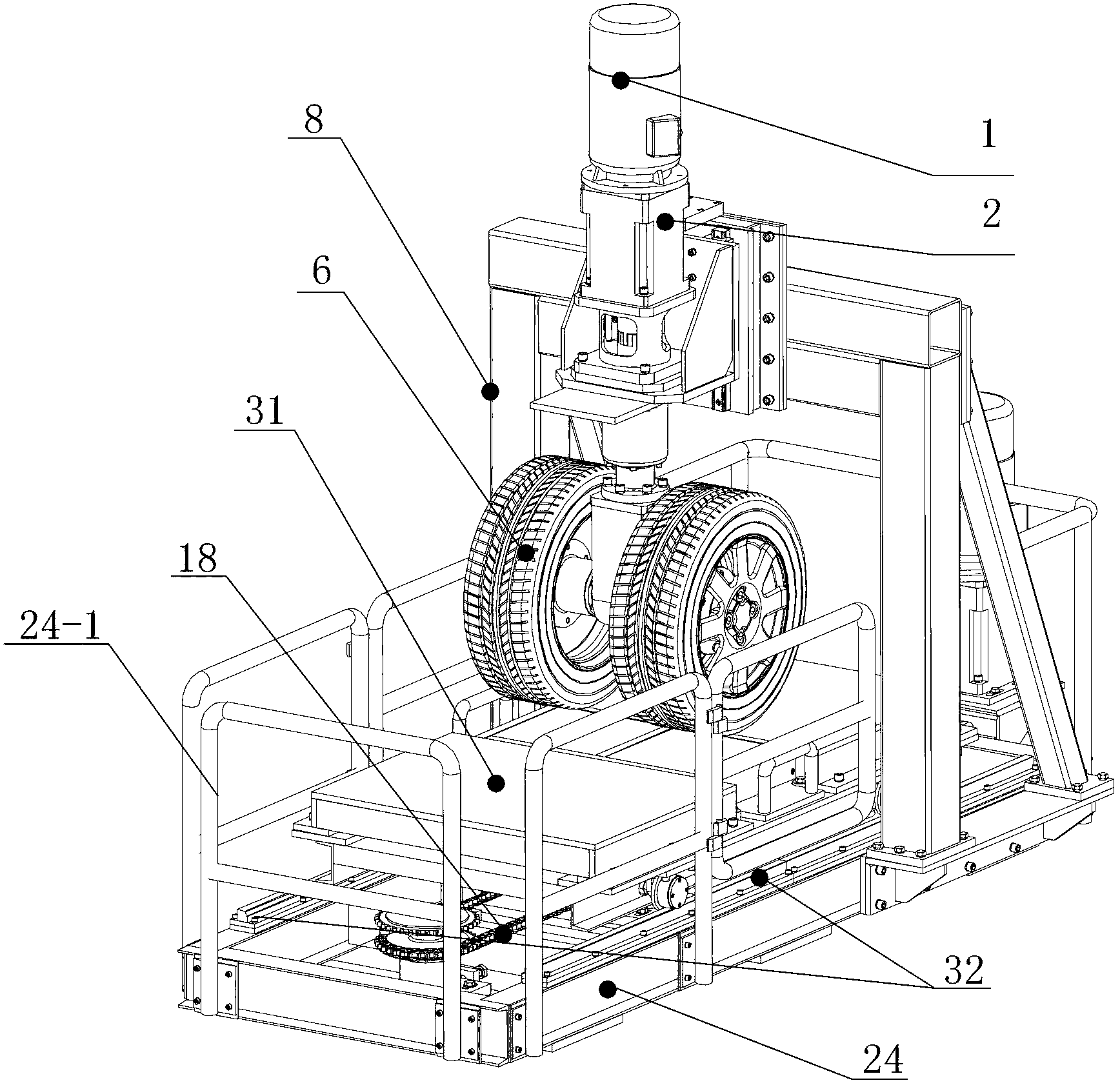

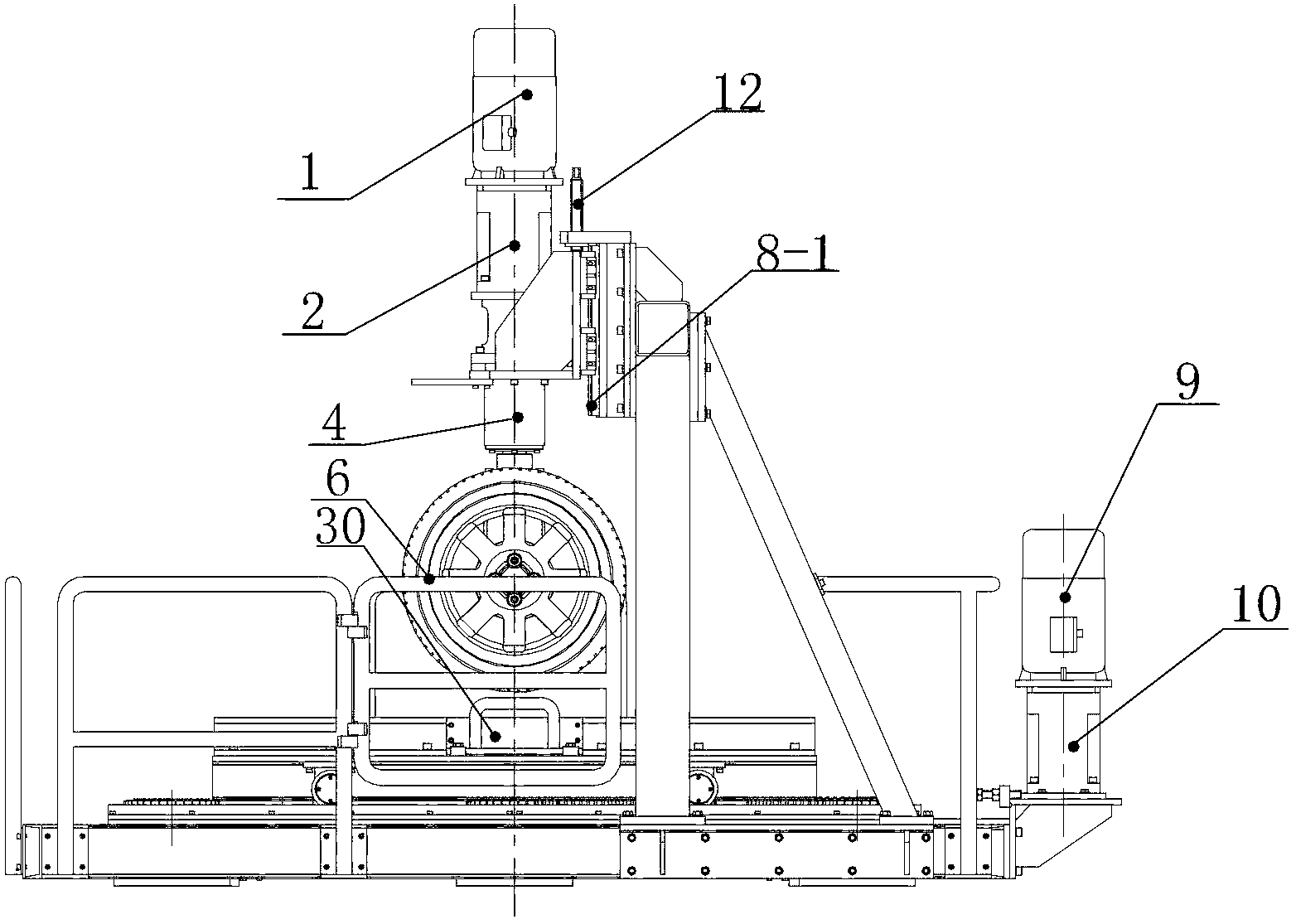

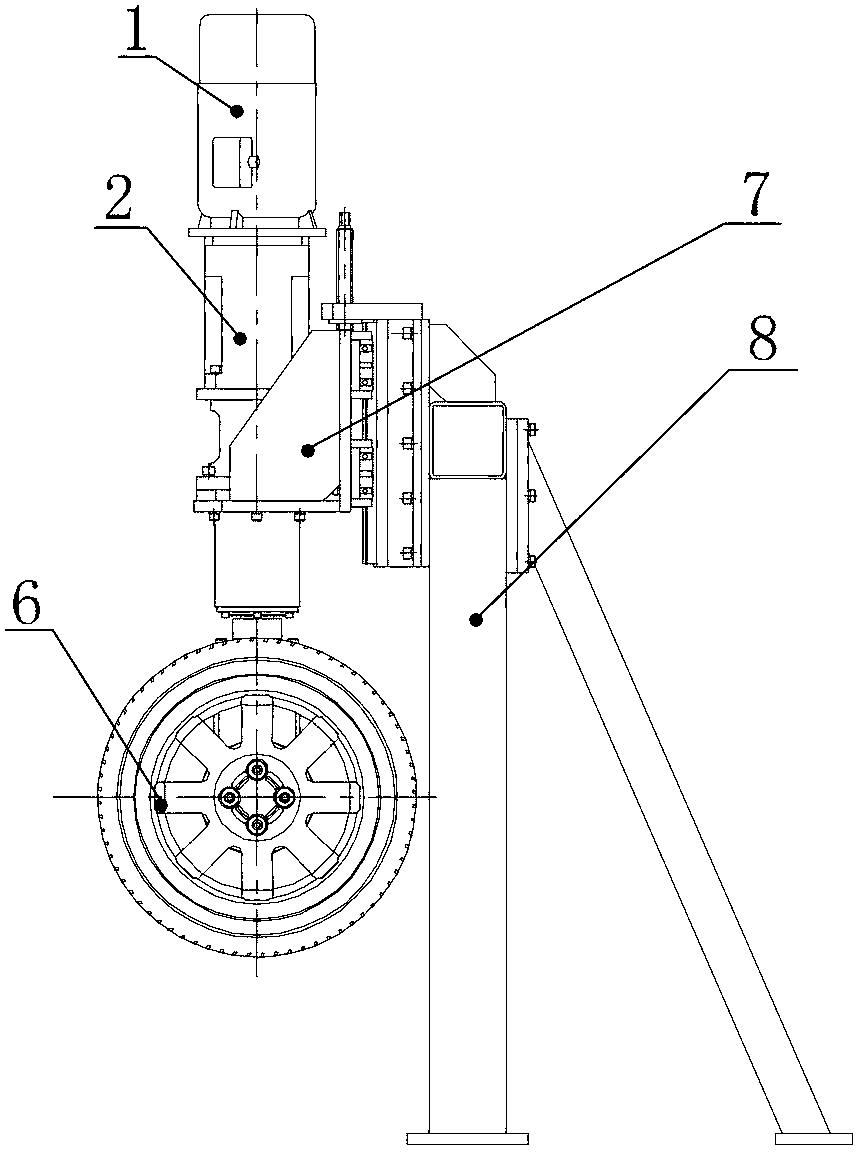

[0012] Specific implementation mode one: combine Figure 1-Figure 8 Describe this embodiment, the grinder of this embodiment comprises a first motor 1, a first reducer 2, a shaft coupling 3, a main shaft 4, a wheel shaft 5, a first reducer frame 7, a side frame 8, a second Motor 9, second reducer 10, belt transmission mechanism 11, second wheel 13, first shaft 14, first chain 15, third wheel 16, fourth wheel 17, second chain 18, fifth wheel 19, the first Triaxial 20, second reducer base 23, base 24, vehicle frame 25, two first wheels 26, two second wheels 27, first iron stopper 28, second iron stopper 29, specimen fixture 30, The second shaft 33, two first stoppers 21, two second stoppers 22, two tires 6, two transition plates 31 and two first guide rails 32, the output shaft of the first motor 1 and the first deceleration The input shaft of the machine 2 is connected by transmission, the output shaft of the first reducer 2 is connected by transmission with one end of the mai...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 4 and Figure 6 Describe this embodiment, the described grinder of this embodiment also comprises adjustment pad 35 and force sensor 36, and adjustment pad 35 is contained on the vehicle frame 25, and force sensor 36 is contained on the first speed reducer frame 7, The load cell 36 is provided with four pressure contacts 36-1, the four pressure contacts 36-1 are located between the test piece fixture 30 and the adjustment pad 35 and the four pressure contacts 36-1 are all in contact with the two, The load cell 36 at the bottom can accurately measure whether the pressure of the tire 6 on the test piece meets the test requirements. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 2 Describe this embodiment, the grinder of this embodiment also comprises screw rod 12 and two second guide rails 8-1, two second guide rails 8-1 are arranged in parallel on side frame 8, first speed reducer support 7 and The two second guide rails 8 - 1 are slidingly connected, and one end of the screw rod 12 abuts against the base 7 of the first reducer. This structure is used to adjust the positions of the first motor 1 and the first reducer 2 . Other implementation manners are the same as the third embodiment.

[0020] working principle:

[0021] Place the prepared test piece 34 in the test piece fixture 30, use a wrench tool to twist the screw 12, so that the tire 6 is lowered to the surface of the test piece 34, and at this time, four pressure contacts 30-1 are used to detect that the tire 6 is in contact with the sample The pressure on the surface, so that according to the test requirements, the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com