T-type high energy beam welding joint shear strength test piece and manufacturing method thereof

A high-energy beam welding, shear strength technology, applied in the direction of using a stable shear force to test the strength of materials, preparation of test samples, etc., can solve problems such as shear resistance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described by examples below, but it should be noted that the purpose of announcing the embodiments is to help further understand the present invention, but those skilled in the art can understand: without departing from the spirit of the present invention and the appended claims Various substitutions and modifications are possible within the scope. Therefore, the present invention should not be limited to the content disclosed in the embodiments, and the protection scope of the present invention is subject to the scope defined in the claims.

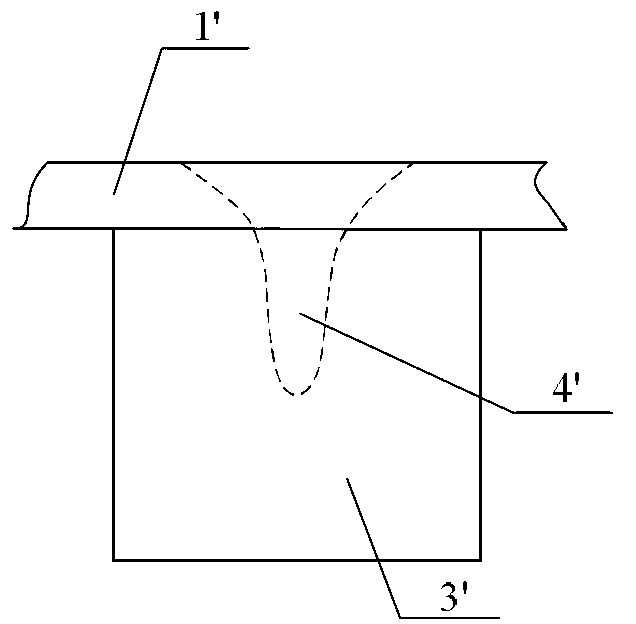

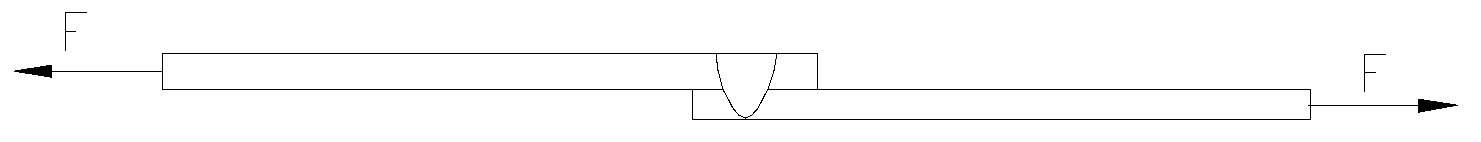

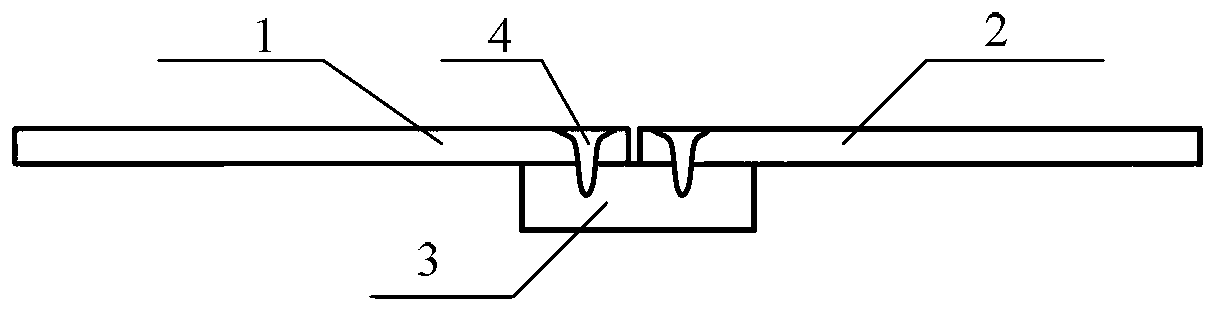

[0026] A shear strength test piece of a T-shaped high-energy beam welded joint, such as image 3 As shown, it includes two upper plates 1 and 2 of the test piece and one lower plate 3 of the test piece. The upper plates of the two test pieces are made of the same thickness and on the same plane. The test piece is placed on the lower plate 3, and the two welds 4 are parallel.

[0027] A method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com