Constant-temperature water tank for water cooling chiller performance testing system

A chiller and test system technology, which is applied in the field of construction environment and equipment engineering, can solve the problems of redundant and unable to achieve constant water temperature, etc., achieve energy saving, be conducive to energy-saving operation, and solve the effects of water temperature stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

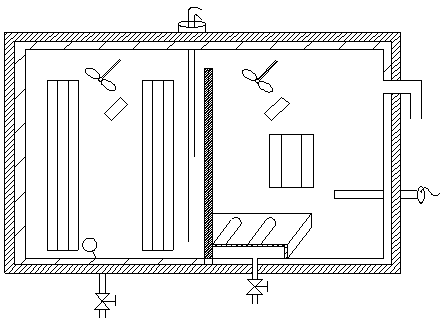

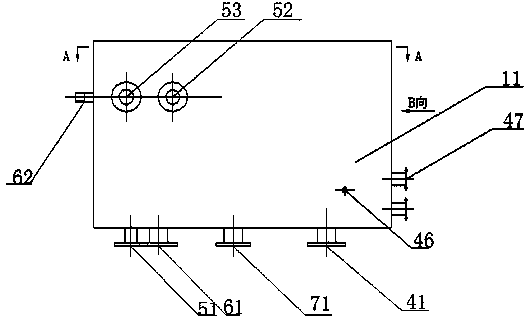

[0032] The constant temperature water tank for the water-cooled chiller performance test system of the present invention includes a box body 1, a longitudinal partition 2, an overflow cavity 7 and a transverse partition 3, and is arranged on the front facade 11 and the rear facade 12 of the box body 1 The longitudinal partition 2 between the box body 1 is divided into left and right two areas, the right area is the constant temperature control area 4, the overflow chamber 7 is arranged in the left area and separated from the longitudinal The plates 2 are connected, and the partition height of the overflow chamber 7 is higher than the height of the longitudinal partition 2 and the transverse partition 3. An overflow hole 71 is arranged on the bottom plate of the overflow chamber 7, and the transverse partition 3 is arranged on the left side. In the area, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com