Drain energy utilization system of steam header continuous blowdown flash tank

A technology of blowdown expansion and vessel expansion, which is applied in the field of steam drum continuous sewage blowdown expansion vessel drainage energy utilization system, can solve the problems of unit efficiency reduction, drainage energy waste, and poor energy utilization rate, so as to reduce extraction steam consumption and overall The layout is simple and the effect of reducing coal consumption for power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

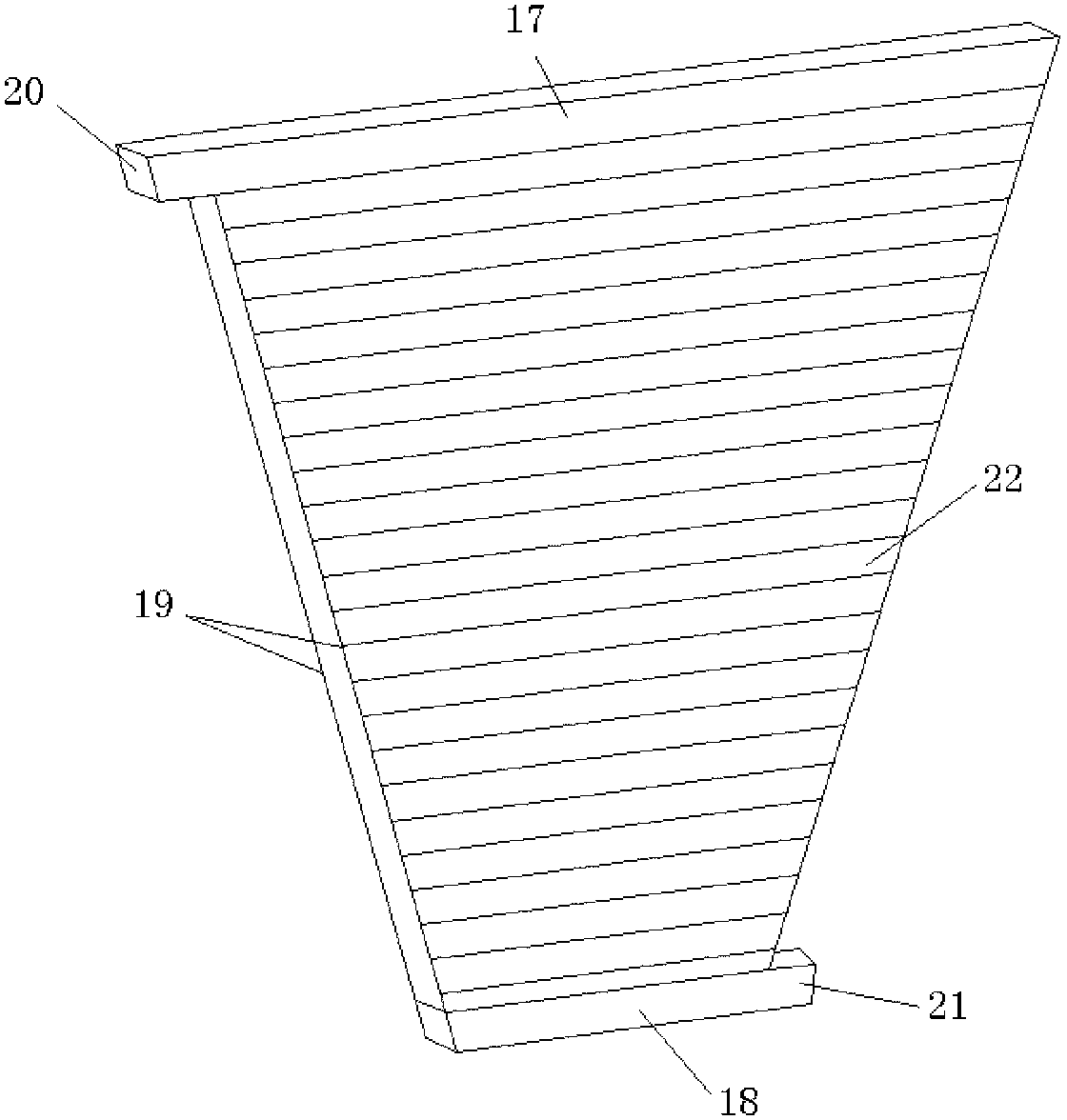

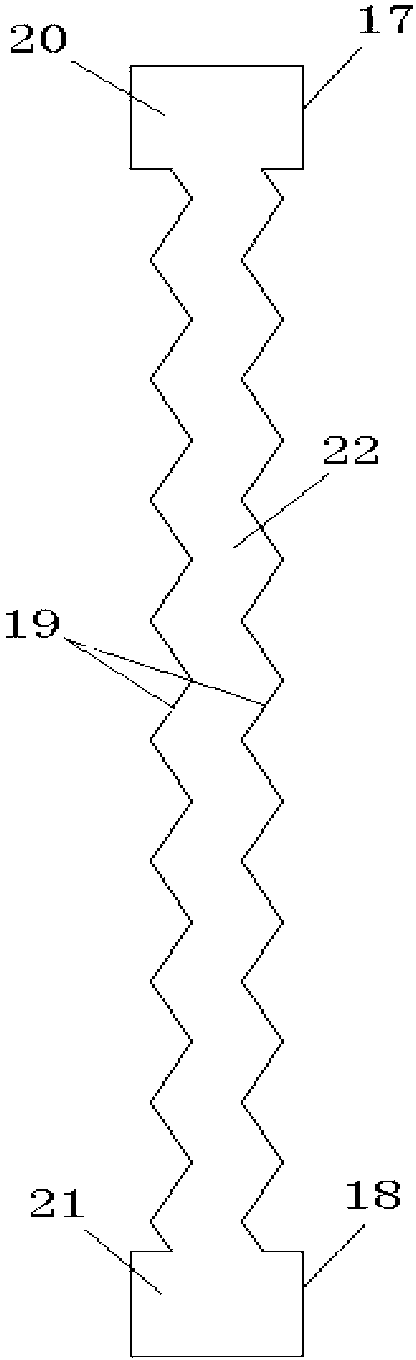

[0022] A steam drum continuous blowdown expansion vessel drainage energy utilization system, such as Figure 1 to Figure 3 As shown, it includes continuous sewage expansion container 12 and regular sewage expansion container 14. Continuous sewage expansion container 12 is connected with regular sewage expansion container 14 through continuous sewage expansion container drainage pipeline 13. 13 is provided with a hydrophobic energy utilization device connected in parallel with the regular sewage expansion vessel 14, and the hydrophobic energy utilization device includes a steam generator 2, a dust collector ash hopper heater 6, a denitrification system liquid ammonia evaporator 11, connecting pipes and valves; The generator 2 is connected to the continuous sewage expansion vessel 12, the steam generator 2 is a vertical structure, the top is a steam outle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap