Shield structure formed by shallow tunneling method in air-pressure mode

A technology of shallow buried underground excavation and air pressure mode, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as excessive wear of cutter heads, unsuitable manual excavation, poor geological stability, etc., to reduce maintenance rate, The effect of improving working time and work efficiency and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

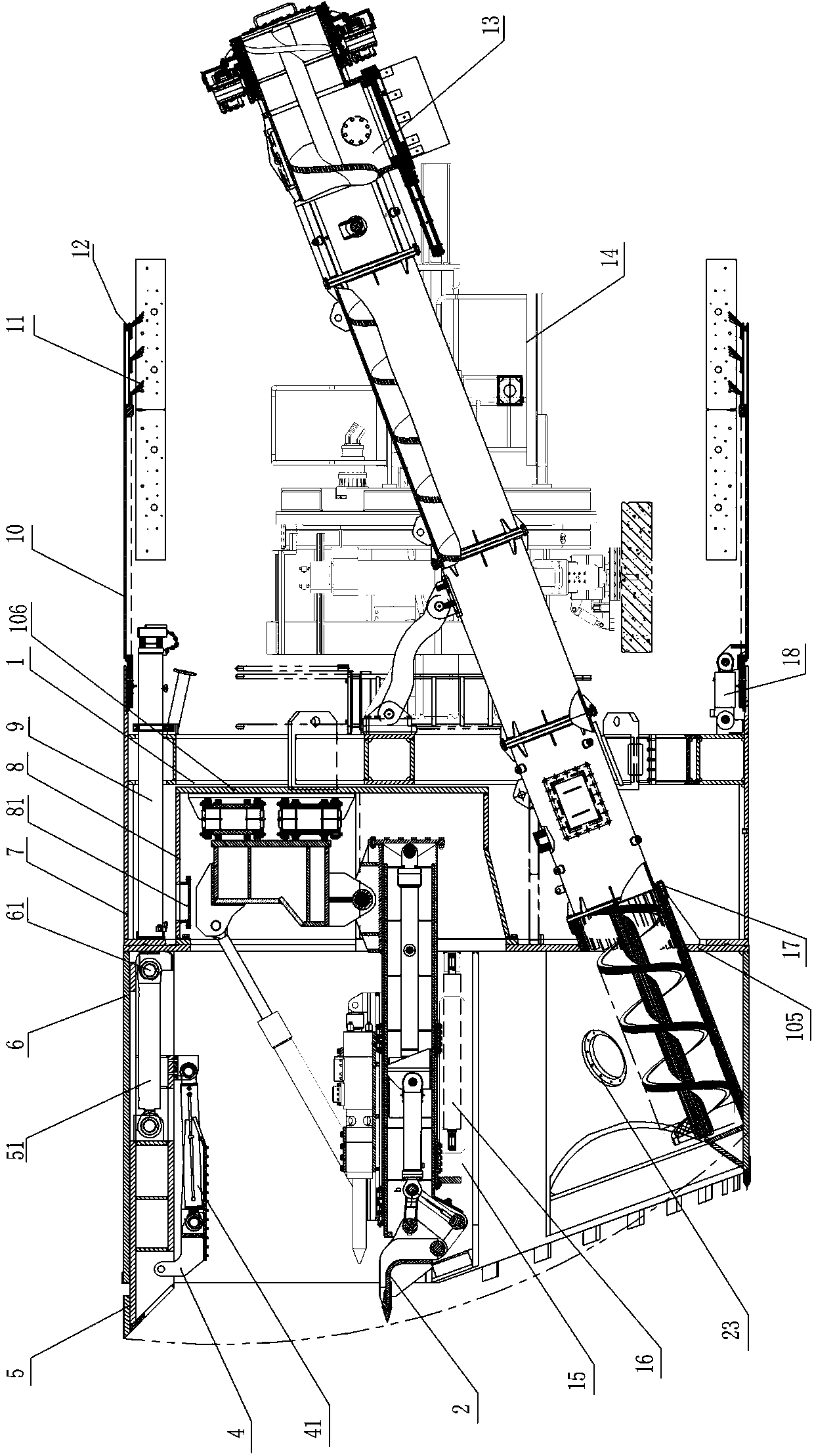

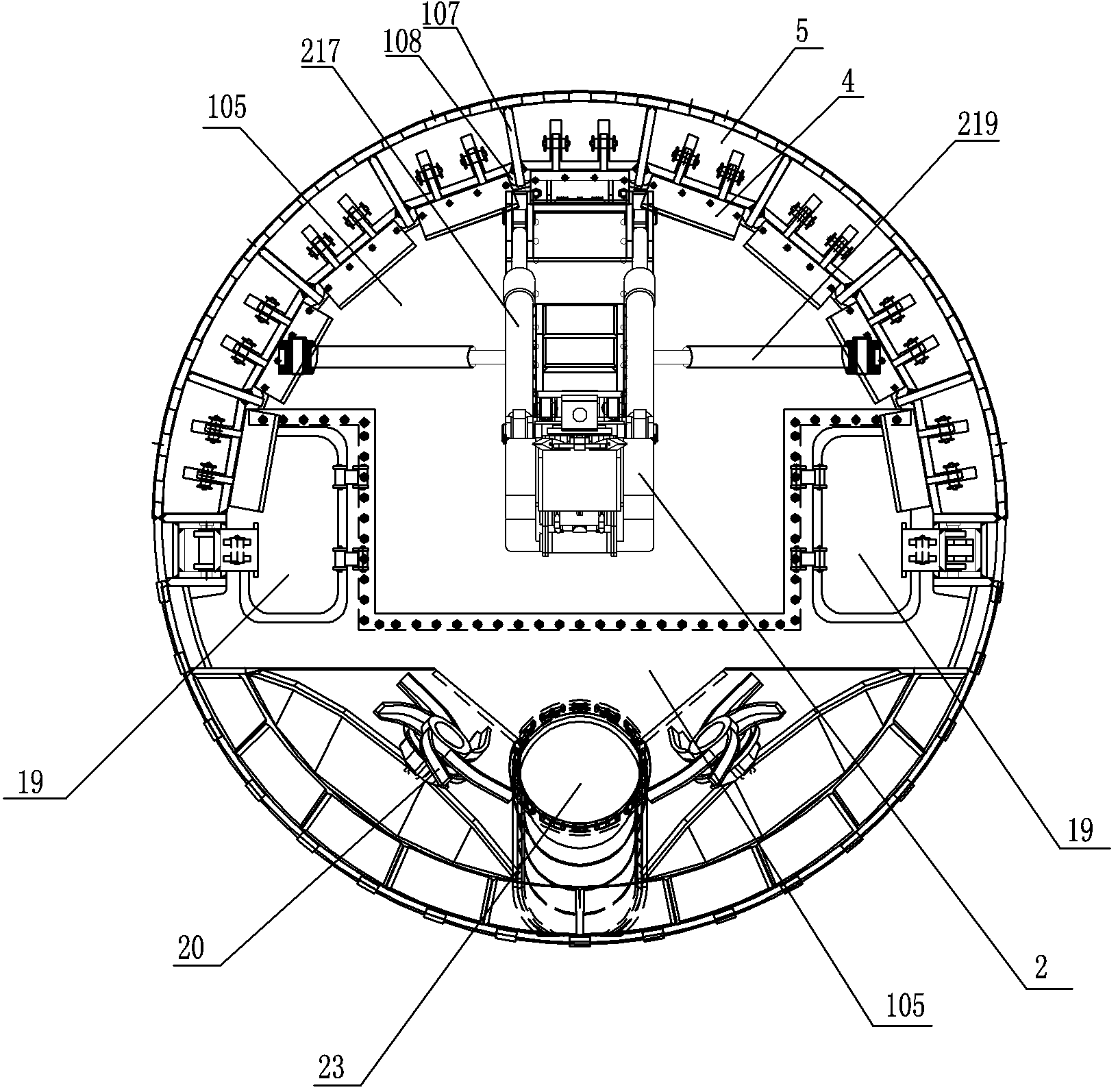

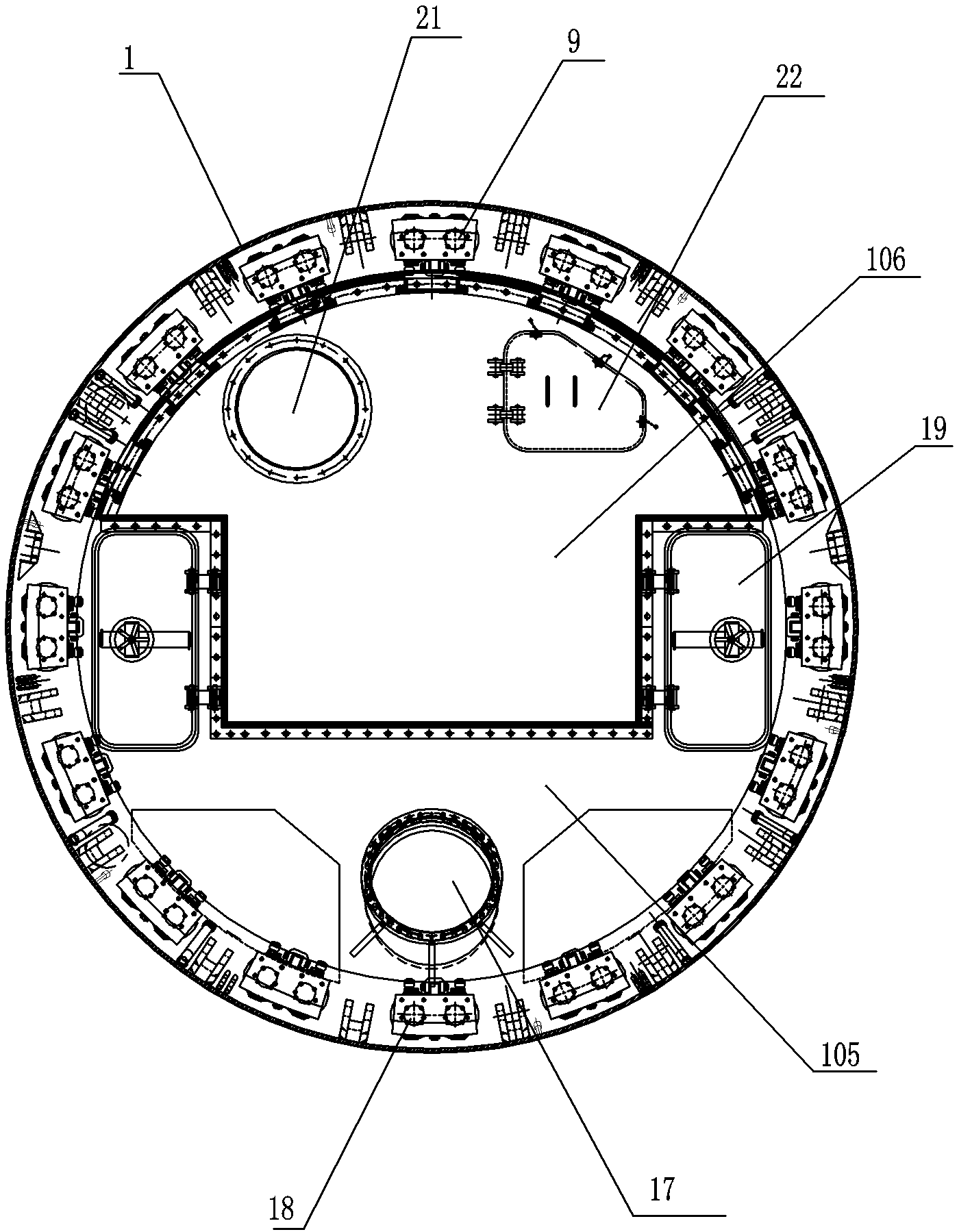

[0027] Embodiment one: see figure 1 , figure 2 and image 3 , the air pressure mode shallow buried undercover excavation method shield includes a cylindrical front shield 6, a cylindrical middle shield 7 and a cylindrical back shield 8. The support shell 1 inside the cylindrical middle shield 7 drives the cylinder The propulsion system 9 etc. that the shield advances in shape. Wherein, a support partition is provided at the junction of the cylindrical front shield 6 and the cylindrical middle shield 7 , and the support partition is divided into a front partition 105 and a rear partition 106 . The front partition 105 is located between the cylindrical front shield 6 and the cylindrical middle shield 7, and the rear partition 106 is located inside the cylindrical middle shield. The front bulkhead 105 and the rear bulkhead 106 are sealed and fixed together to form a sealing device 8 , a through hole 81 is arranged on the top plate of the sealing device 8 and an openable and c...

Embodiment 2

[0042] Embodiment two: accompanying drawing is not drawn, can refer to Figure 4 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the excavator is only mounted on the rear bulkhead in an up-and-down mode, that is, the rear end of the outer sleeve of the excavator is hinged on the rear bulkhead Or be hinged on the fixed bracket that the back bulkhead is provided with, the front end of the outer sleeve is hinged with one or two up and down pulling oil cylinders, and the other section of the up and down pulling oil cylinders is hinged on the back bulkhead or on the fixed bracket that the rear bulkhead is provided with. This solution is suitable for parallel installation of multiple excavators, and each excavator performs up and down excavation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com