Digging and anchoring machine integrated with digging, anchoring and drilling

A technology of bolter miners and advanced drilling rigs, which is applied to cutting machinery, earthwork drilling, bolt installation, etc. It can solve the problems of small effective working time ratio, complex structure, and time waste, so as to save bolting time, The effect of increasing the operating space and improving the tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

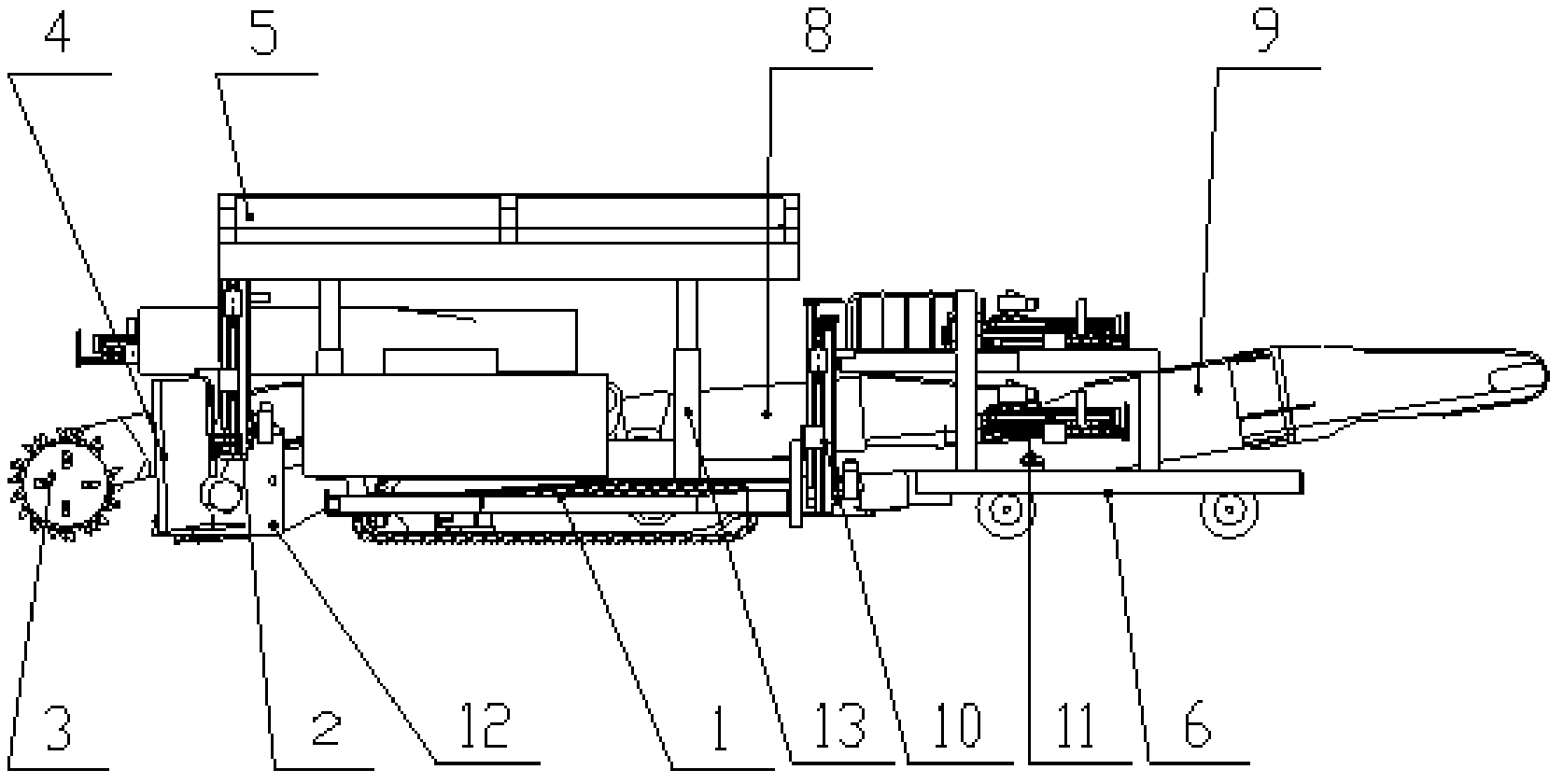

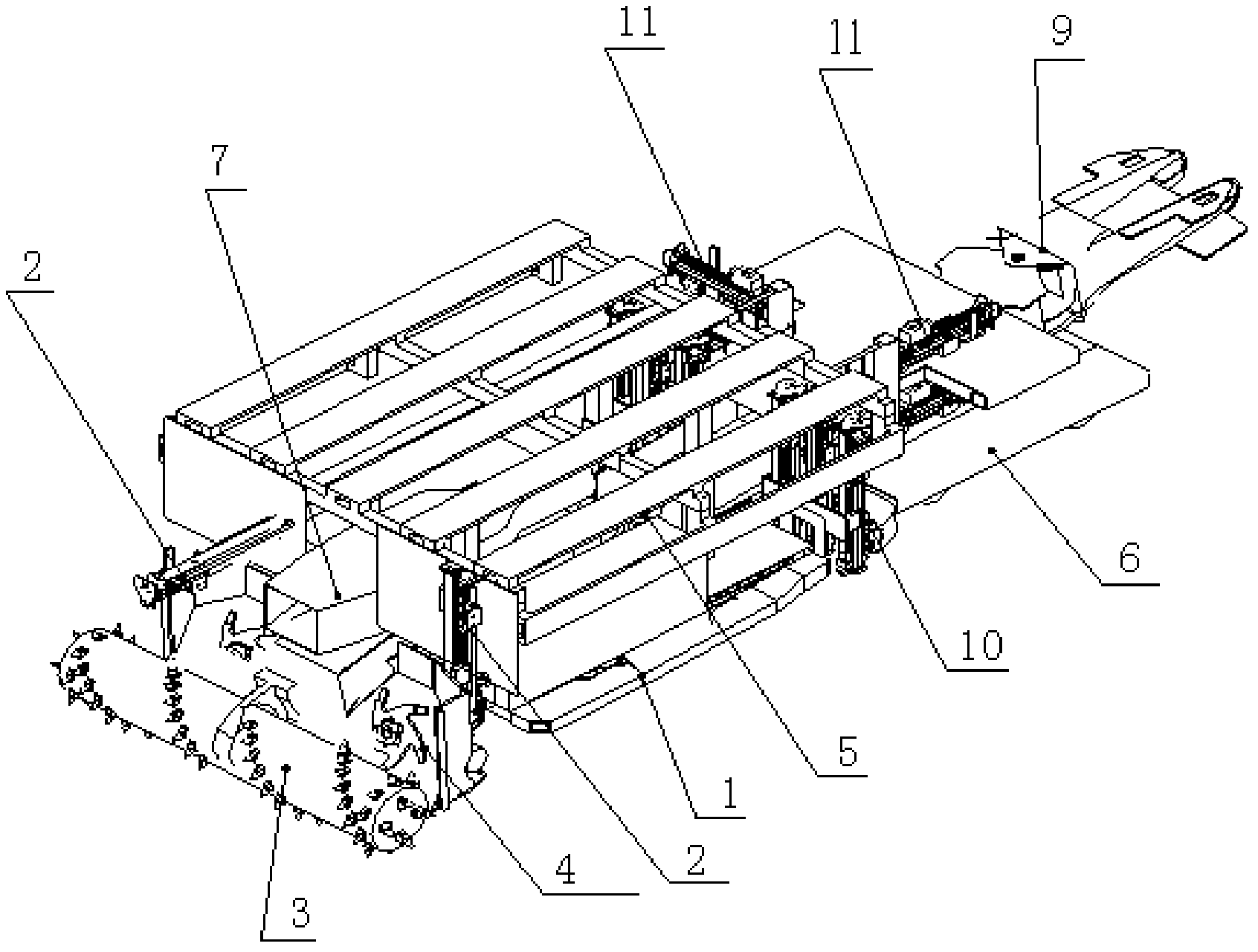

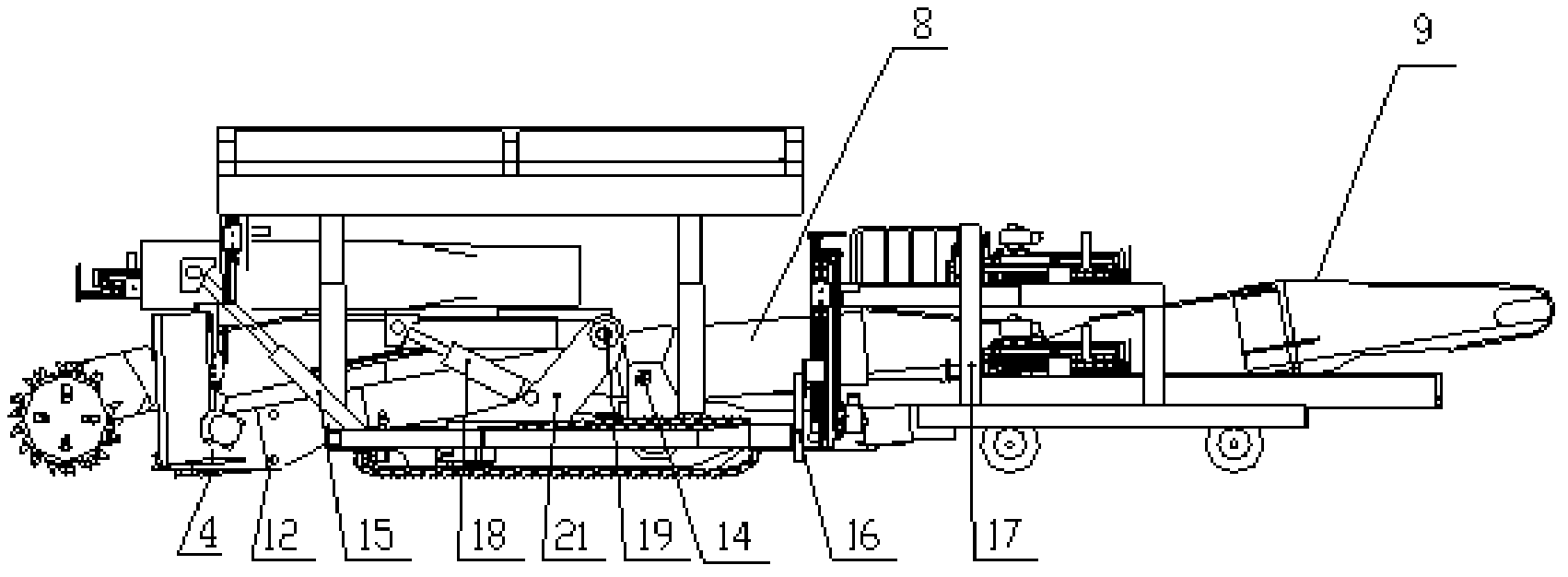

[0023] See figure 1 — image 3 , the integrated bolter drilling machine includes a chassis 1, a cutting device 3 located on the chassis 1, a top bolter 10, an advanced drilling rig 2, a loading device 4, a shield 5, a ventilation and dust removal device 7, and a conveying mechanism 8; It also includes a matching trolley 6 connected to the rear end of the chassis 1; the cutting device 3 is arranged at the front end of the chassis 1, and the shield 5 is arranged above the chassis 1 and behind the cutting device 3; At the rear end of the chassis 1, the loading device 4 is arranged below the cutting device 3, the advanced drilling machine 2 is arranged on the loading device 4, the ventilation and dust removal device 8 is arranged above the loading device 4, and the conveying mechanism 8 is arranged on the loading device 4 , the supporting trolley 6 is provided with a transfer conveyor 9 and a side bolter 11 connected with the conveying mechanism 8 on the chassis 1 .

[0024] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com