Rope-wheel type electric glass lifter

A glass lifter and rope pulley technology, which is applied in the direction of power control mechanisms, buildings, door/window accessories, etc., can solve the problems affecting the expansion of the interior space of the car, and achieve the effect of simple structure, increased interior space and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

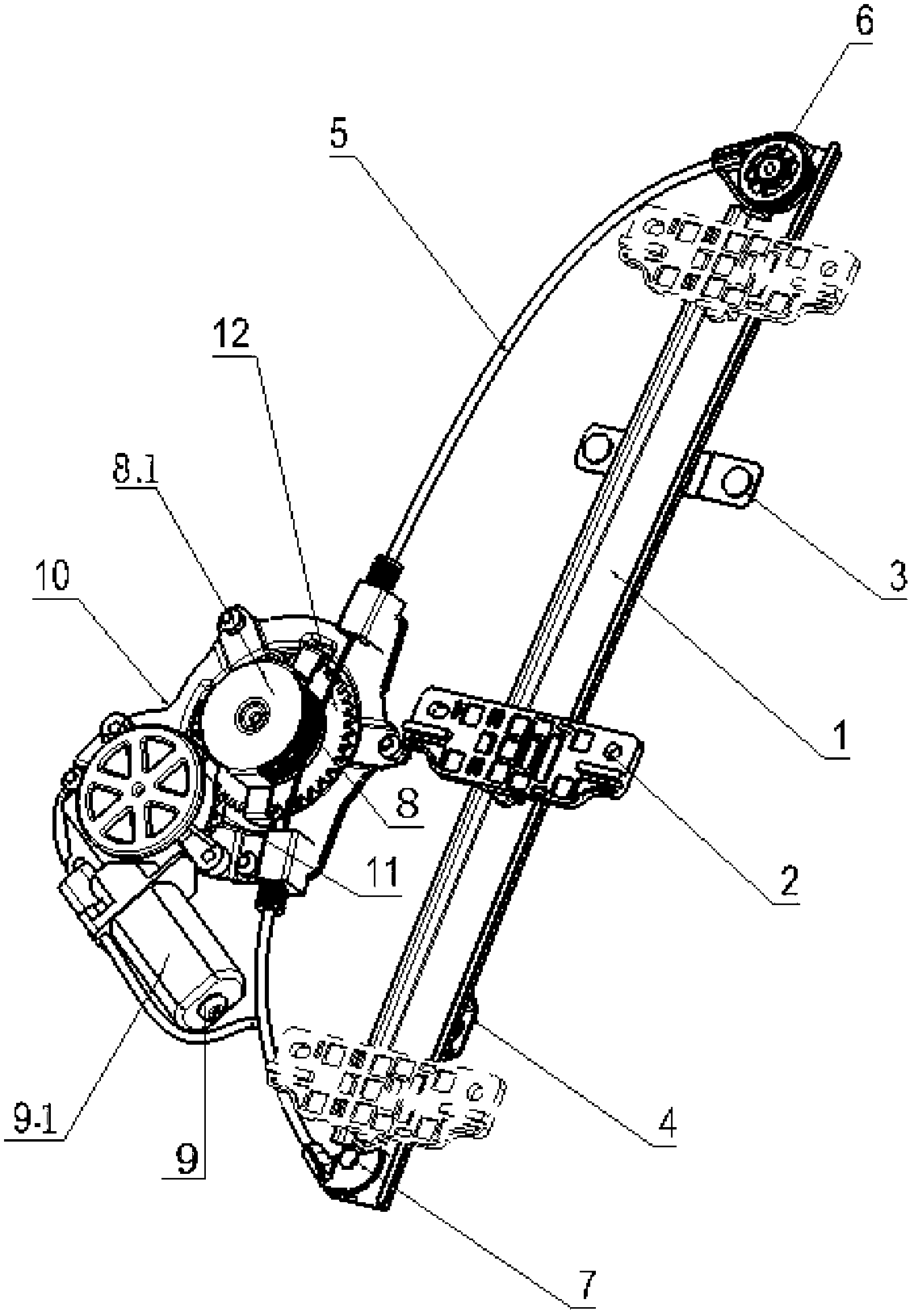

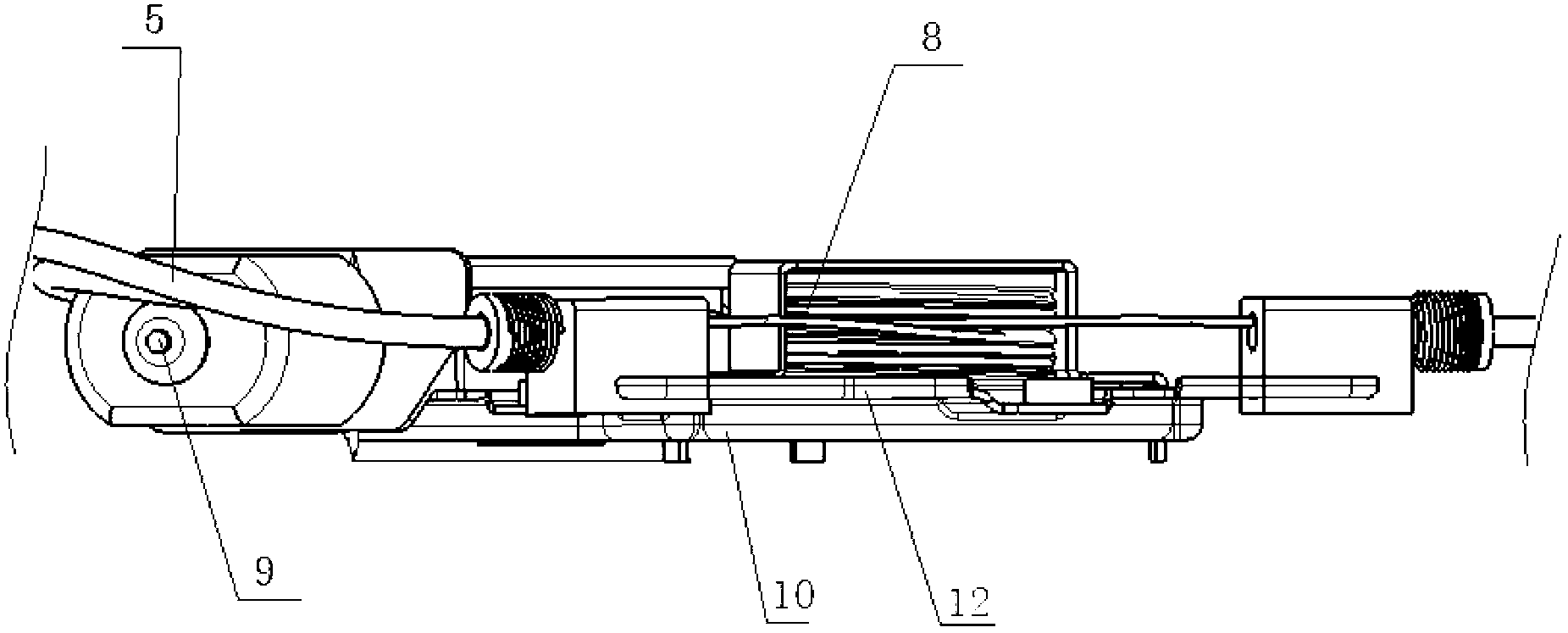

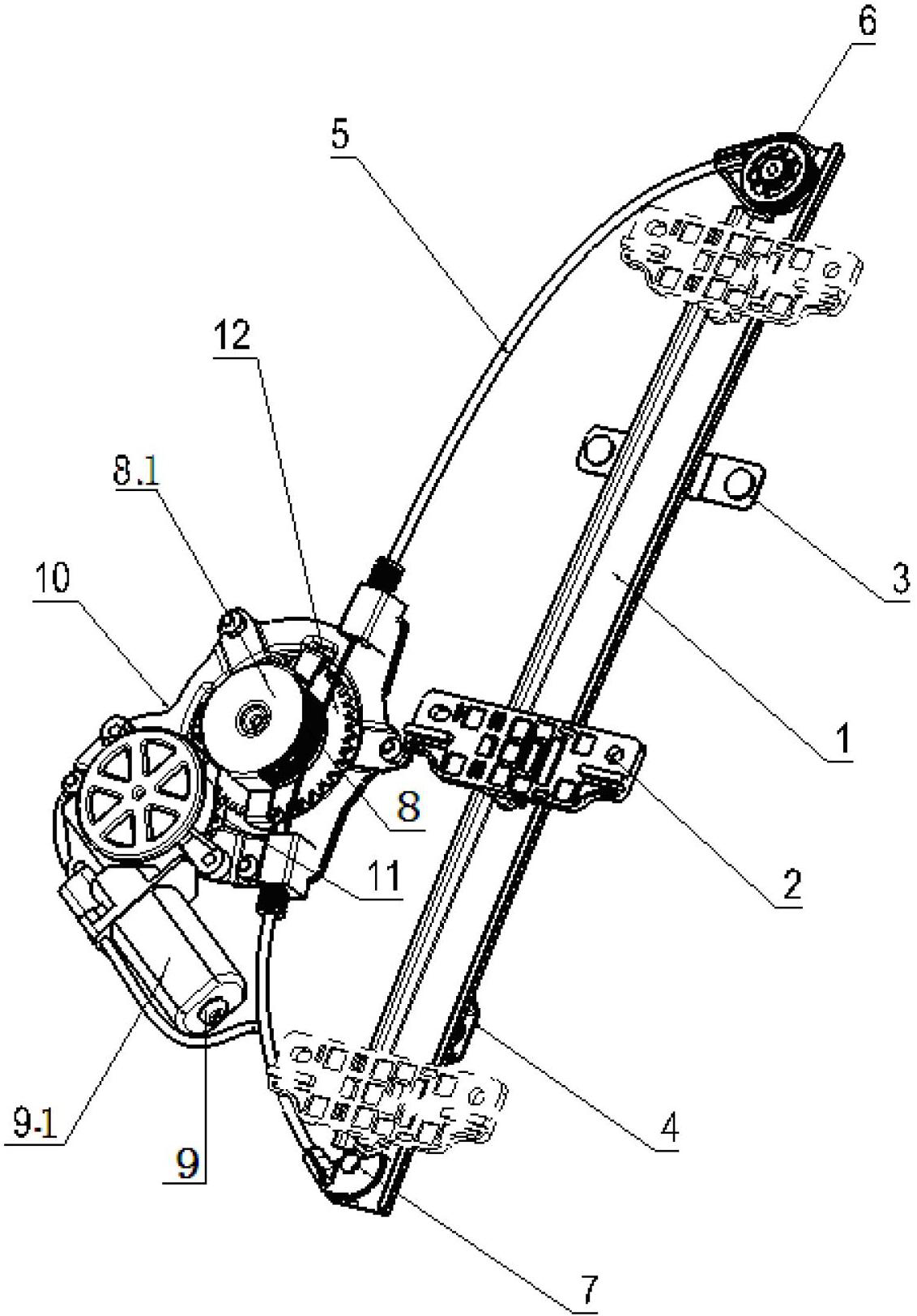

[0013] Such as figure 1 and figure 2 The rope-wheel type electric window lifter shown includes a guide rail 1, a slide plate 2 set on the guide rail 1, an upper wire pulley 6 and a lower wire pulley 7 respectively located at both ends of the guide rail 1, a reel 8, and a winding wire The wire rope 5 and the motor 9 on the barrel 8, the two ends of the wire rope 5 respectively go around the upper guide wheel 6 and the lower guide pulley 7 to connect with the slide plate 2, and also include the driving wheel 11 connected to the output shaft of the motor 9 and mesh with the driving wheel 11. The driven wheel 12, the spool 8 is connected with the output shaft of the driven wheel 12. Motor 9, driving wheel 11 and driven wheel 12 are all installed on the base 10, and base 10 is installed on the car door. The upper surface 8.1 of the reel is on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com