H-shaped steel structural part and production method thereof

A production method and a technology of structural parts, which are applied in the direction of building construction and construction, and can solve problems such as difficulty in ensuring the use effect, deformation, and excessive webs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific structure of the present invention is illustrated below in conjunction with the embodiment given with accompanying drawing.

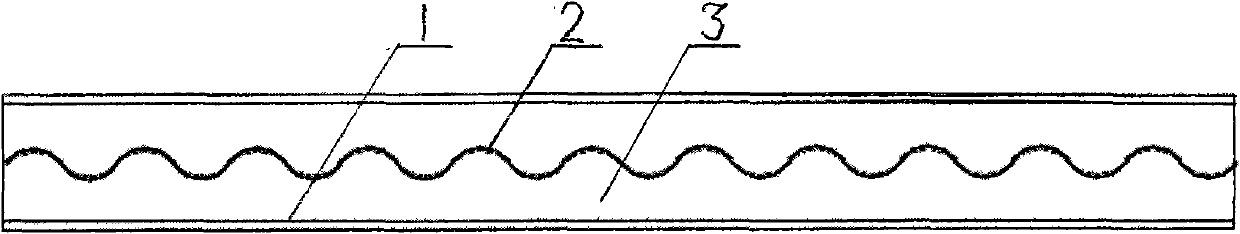

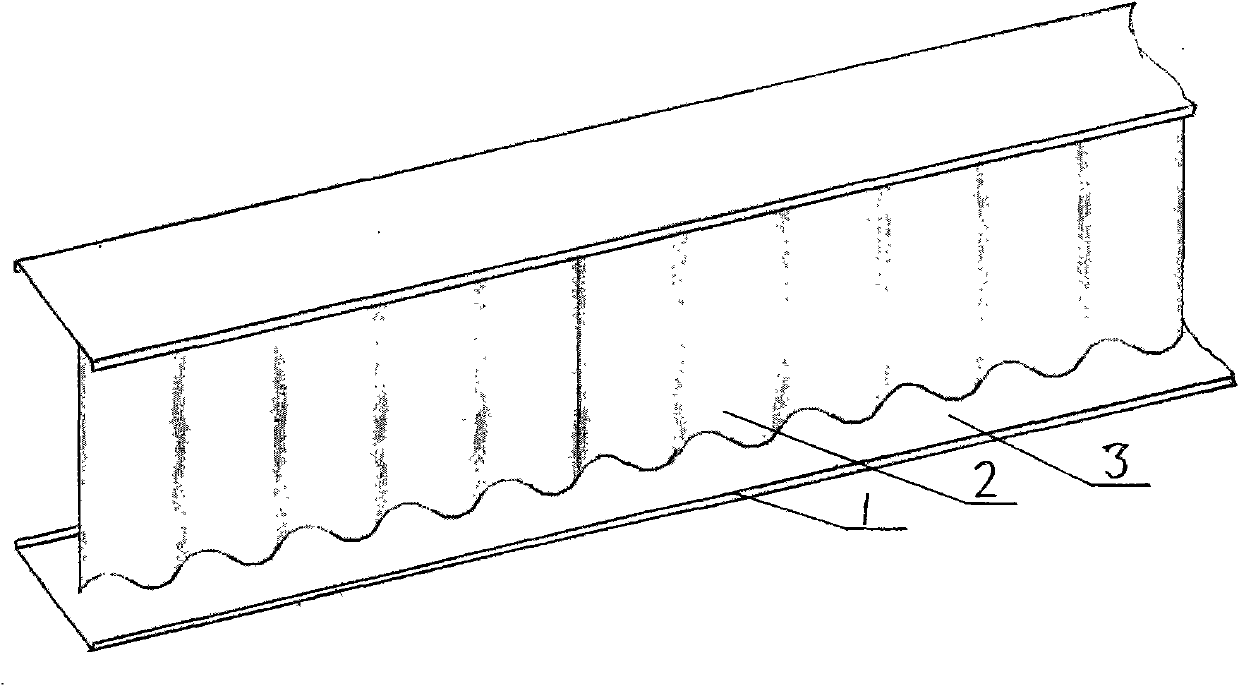

[0023] As shown in the accompanying drawings, an H-shaped steel structure of the present invention has two opposite flange plates 3, and a web 2 with a wavy cross-section is fixed longitudinally between the middle parts of the two flange plates. There are inwardly folded flanges 1 at both edges of the .

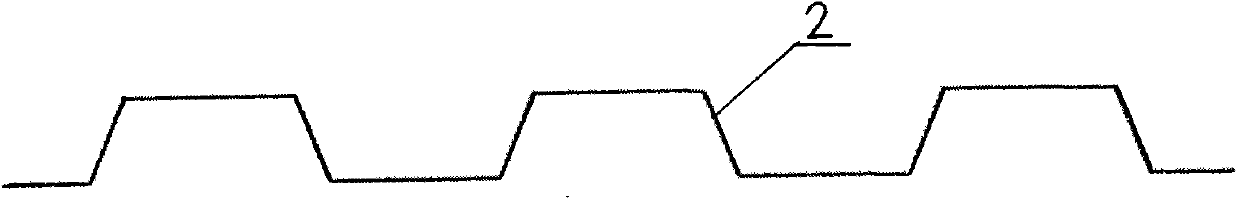

[0024] The wave shape is sine wave or trapezoidal wave, or a combination of sine wave and trapezoidal wave. figure 1 The wave shape of the cross-section of the web in is a sine wave. image 3 The cross-section of the web shown is trapezoidal. When the combination of sine wave and trapezoidal wave is used, one section of the web is a sine wave cross section and the other section is a trapezoidal wave cross section, or the two cross sections are arranged alternately.

[0025] Weld and fix the connection plate 4 at the two ends of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com