Intelligent optimal control system for CO2 emission of blast furnace

A control system, intelligent optimization technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problem that the control system cannot provide emission optimization control references, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

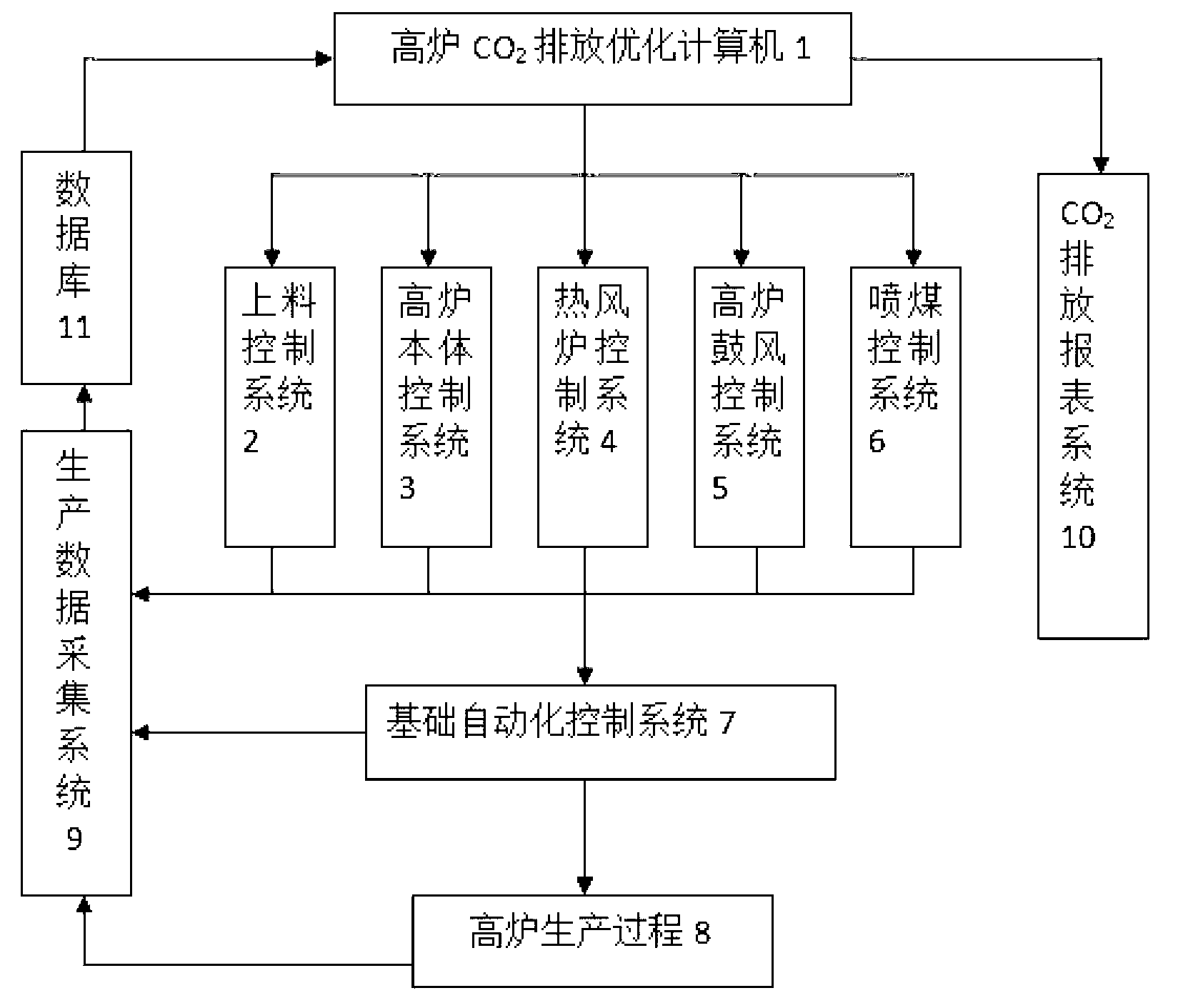

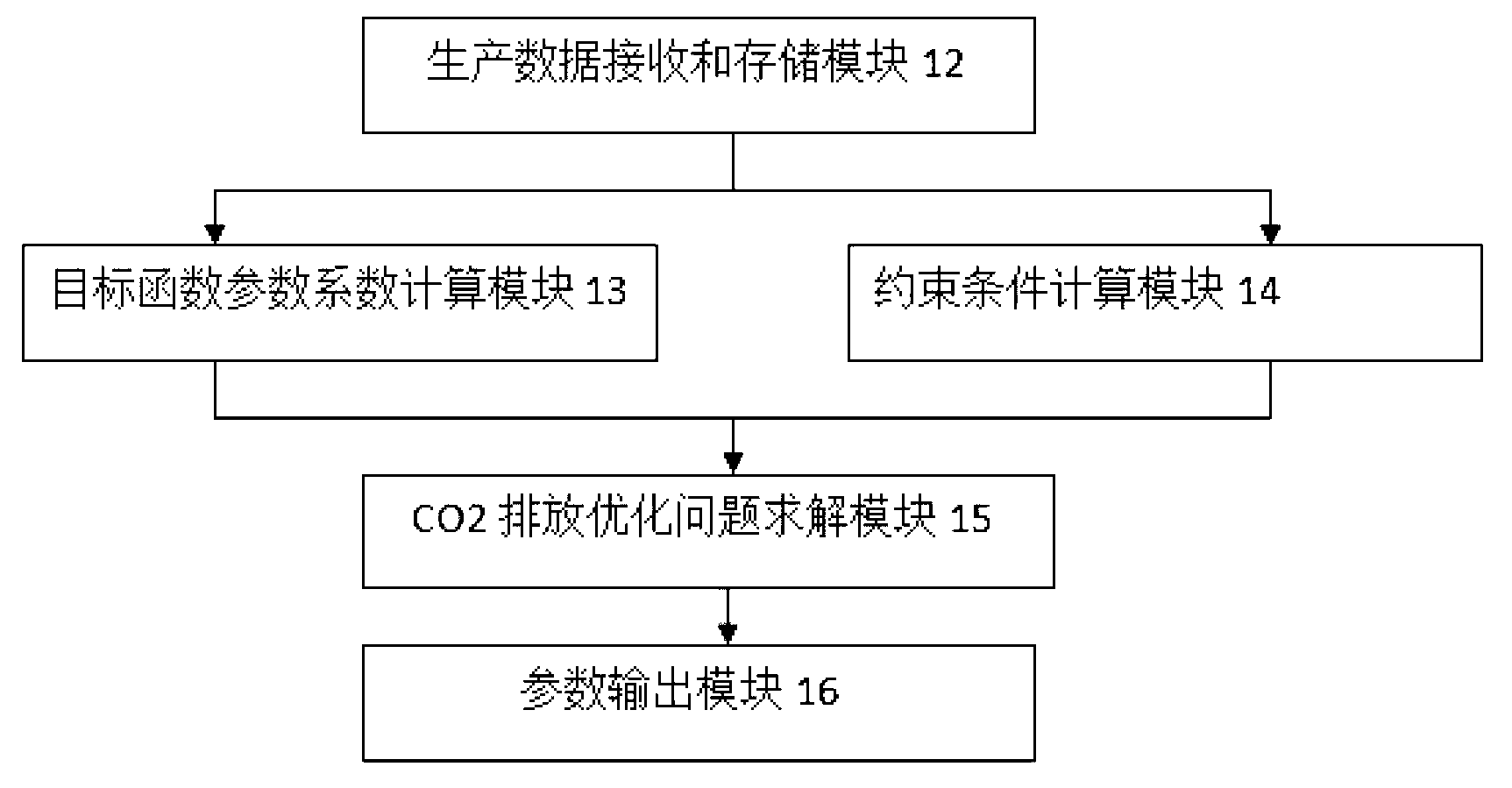

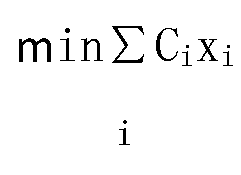

[0019] A blast furnace CO of the present invention 2 The emission intelligent optimization control system consists of blast furnace CO 2 Emission optimization computer 1, material feeding control system 2, blast furnace body control system 3, hot blast stove control system 4, blast furnace blast control system 5, coal injection control system 6, basic automation control system 7, blast furnace production process 8, production data collection System 9, CO 2 Emission statement system 10, database 11; It is characterized in that blast furnace CO 2 Emission optimization computer 1 and database 11 constitute blast furnace CO 2 Emission reduction optimization platform; production data acquisition system 9 and blast furnace production process 8, basic automation control system 7, feeding control system 2, blast furnace body control system 3, hot blast stove control system 4, blast furnace blast control system 5, coal injection control System connection 6, real-time collection of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com