Application of hydrophilic Ge-ZSM-5 molecular sieve membrane to separation of organics/water system

A technology of ge-zsm-5 and organic matter, which is applied in the field of separation of organic matter/water system by hydrophilic molecular sieve membrane, can solve the problems of low separation efficiency, separation factor and permeation flux cannot be large enough at the same time, and achieve good separation Effect, large permeation flux, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] Add 20% tetrapropylammonium hydroxide (TPAOH) into a 100 mL three-necked flask containing deionized water, and vigorously stir at room temperature for 10 minutes. Silica sol (Ludox AS-40) was slowly added dropwise to the aforementioned sol, tetraethoxygermanium (Ge(C 2 h 5 O) 4 ) was dissolved in isopropanol, slowly added dropwise to the aforementioned colloid in an ice-water bath, and vigorously stirred for about 20 minutes. Move the colloid into the water bath, heat up to 80°C, stay at this temperature for about 10 minutes to remove the alcohol in the colloid, then remove the water bath, and replenish the water lost in the evaporation process. Remove from the water bath, and continue vigorously stirring at room temperature for 3 hours to age to obtain a milky white synthetic solution. The molar composition of the synthetic solution is 0.195 Ge(C 2 h 5 O) 4 : 19.5 SiO 2 : 1.0 TPAOH : 438 H 2 O. Synthetic solution and α-Al 2 o 3 The carrier is placed togeth...

Embodiment approach 2

[0019] Apply the Ge-ZSM-5 molecular sieve membrane prepared in Embodiment 1 of the present invention, before performing the pervaporation experiment, first pass a single-component permeation test to check the compactness of the molecular sieve membrane, and pass 0.3 MP on the front side of the membrane. h 2 , test the pressure of the gas on the back side of the membrane, the pressure is 0.0 MP, it is considered that the membrane layer is relatively dense and has no defects.

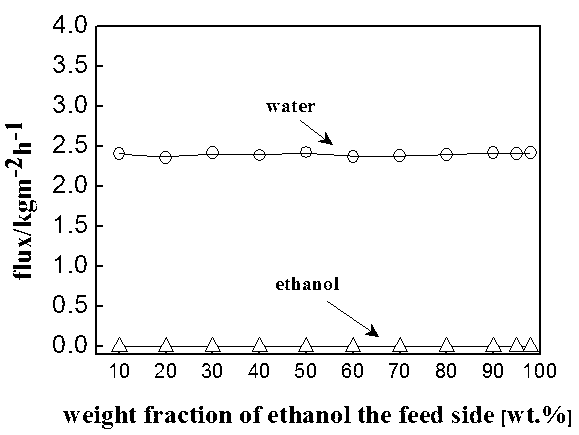

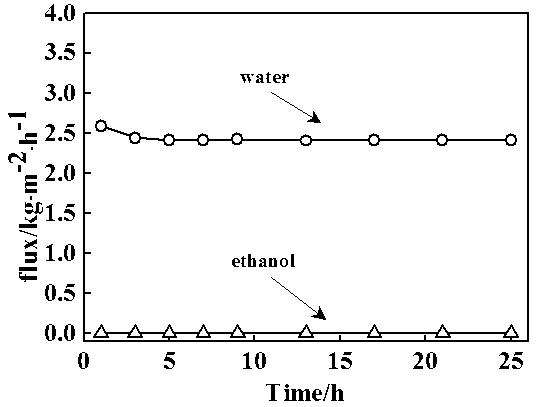

[0020] 10-98 wt.% ethanol aqueous solution is used as the raw material solution, and the temperature of the raw material solution is kept at 353 K. The permeate side is evacuated by a vacuum pump, and the permeate through the membrane layer is collected by condensation with liquid nitrogen. Samples are taken every hour, and the GC-950 gas chromatograph is used to detect the change of the permeate composition, and the quality of the permeate is weighed. Calculate the separation factor and permeation flux,...

Embodiment approach 3

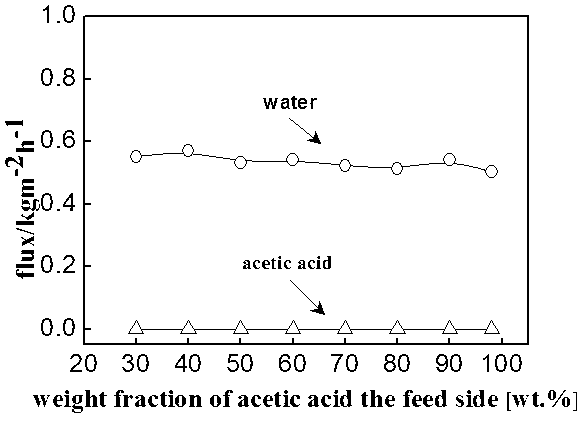

[0022] Applying the Ge-ZSM-5 molecular sieve membrane prepared in Embodiment 1 of the present invention is based on Embodiment 2, and 30-98 wt.% acetic acid aqueous solution is used as the raw material liquid, and the constant temperature of the raw material liquid is 343 K. The permeate side is evacuated by a vacuum pump, and the permeate through the membrane layer is collected by condensation with liquid nitrogen. Samples are taken every hour, and the GC-950 gas chromatograph is used to detect the change of the permeate composition, and the quality of the permeate is weighed. Calculate separation factors and permeate fluxes. The separation factor is ∞, and the permeate flux reaches 0.57 kg / m 2 h, achieving high efficiency separation. After 25 hours of pervaporation, the separation factor and permeation flux remained basically unchanged, indicating that the membrane layer had stable performance and good acid resistance. The results obtained are listed in the attached figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com