Multi-station trepan boring machine

A multi-station, hole-sleeve technology, used in work accessories, manufacturing tools, stone processing tools, etc., can solve problems such as the influence of the service life of the inner bearing of the clamping device and the unsatisfactory sealing effect of the clamping device, so as to prevent entry Effects inside the clamping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

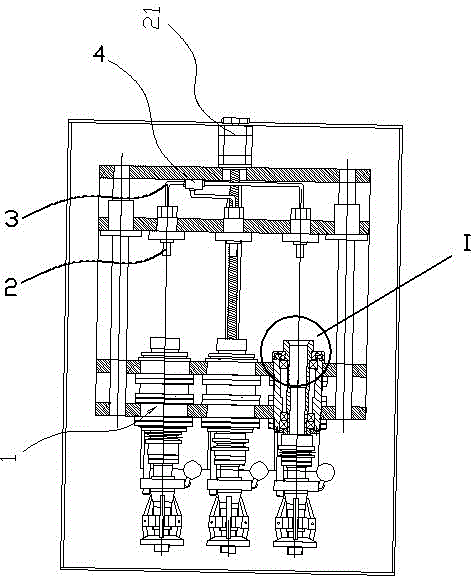

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a multi-station trepanning machine, including a clamping device 1 for clamping and rotating a workpiece to be processed, a cutting head 2, and a driving device 21 for moving the cutting head 2 along a certain straight line, said The rear end of the cutting head 2 is connected with a coolant water pipe 3 , the coolant water pipe 3 is connected with a water pump 4 , and also includes a labyrinth waterproof disk 5 , and the labyrinth waterproof disk 5 is arranged at the front end of the clamping device 1 .

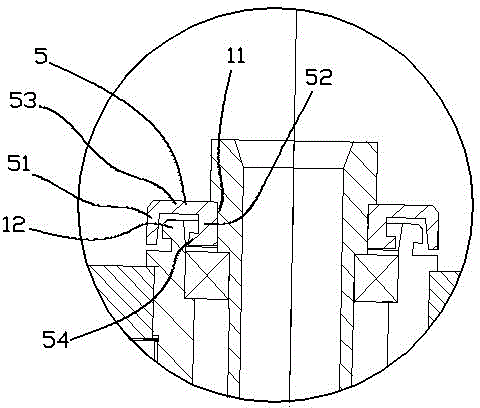

[0011] see figure 2 , the cross-section of the labyrinth waterproof disk 5 is not completely closed rectangle, including a first ring 51, a second ring 52 is arranged at the parallel position of the first ring 51, and the first ring 51 It is fixedly connected with the second ring 52 through the third ring 53, and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com