Method and device for measuring movement locus of automatic tool changing mechanical arm

A technology of mechanical arm and motion trajectory, which is applied in positioning devices, measuring/indicating equipment, metal processing machinery parts, etc., can solve the difficulty of reliability detection methods, the closedness of the overall structure increases the difficulty of motion state detection, and the assembly accuracy has a great impact on terminal motion. The impact of errors is difficult and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

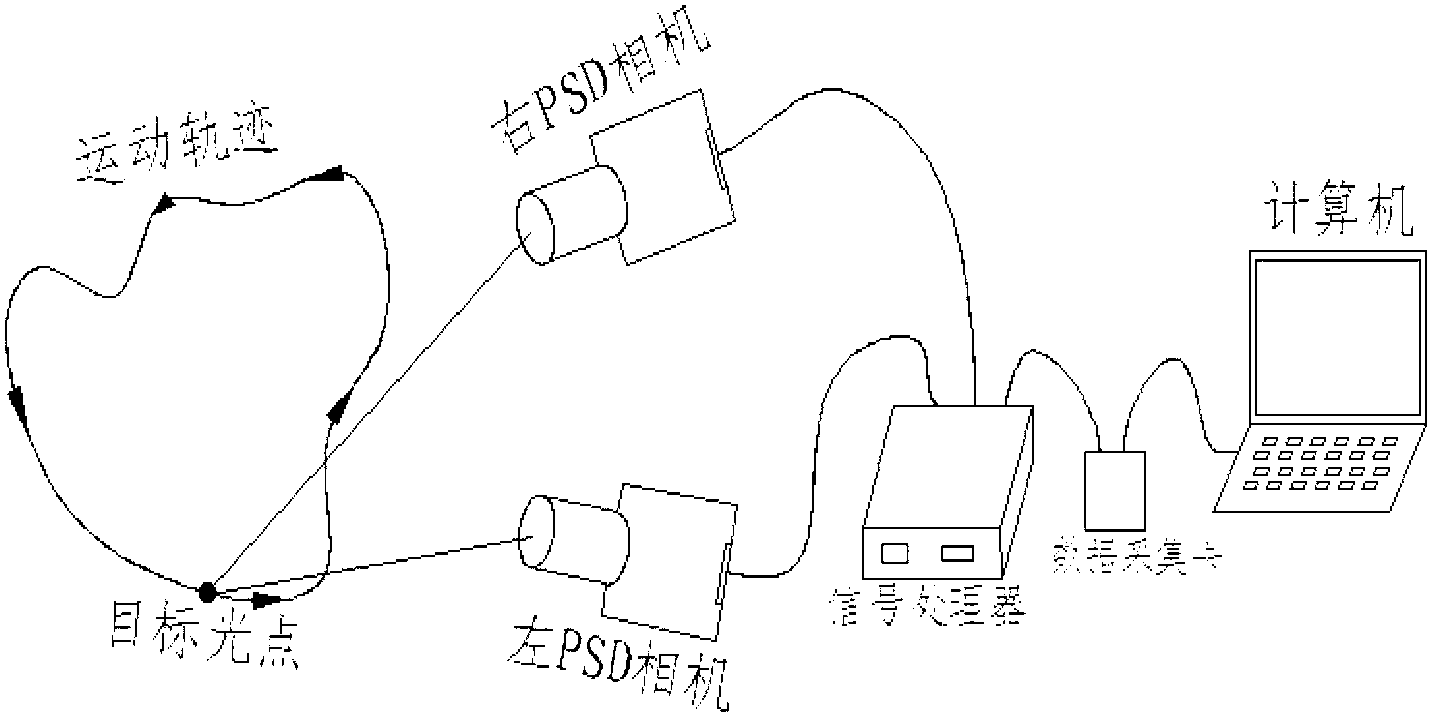

[0041] The present invention is used for on-line measurement of the motion trajectory during the ATC working process. Two LED light sources are installed on the ATC mechanical arm as the tracking target, and two two-dimensional position sensitive detectors are used to detect the projected spot coordinates, and then the three-dimensional position of the target point is calculated. coordinate value. This kind of measuring device measures the target point on the arc cam type ATC mechanical arm, obtains the actual motion state of the automatic tool change mechanism, and compares it with the ideal motion state, so as to "drop the tool", "jitter" and "not moving" "In place" and other abnormal phenomena are predicted and evaluated, forming a means of ATC reliability detection.

[0042] The concrete implementation of the present invention is described in detail below in conjunction with accompanying drawing and technical scheme:

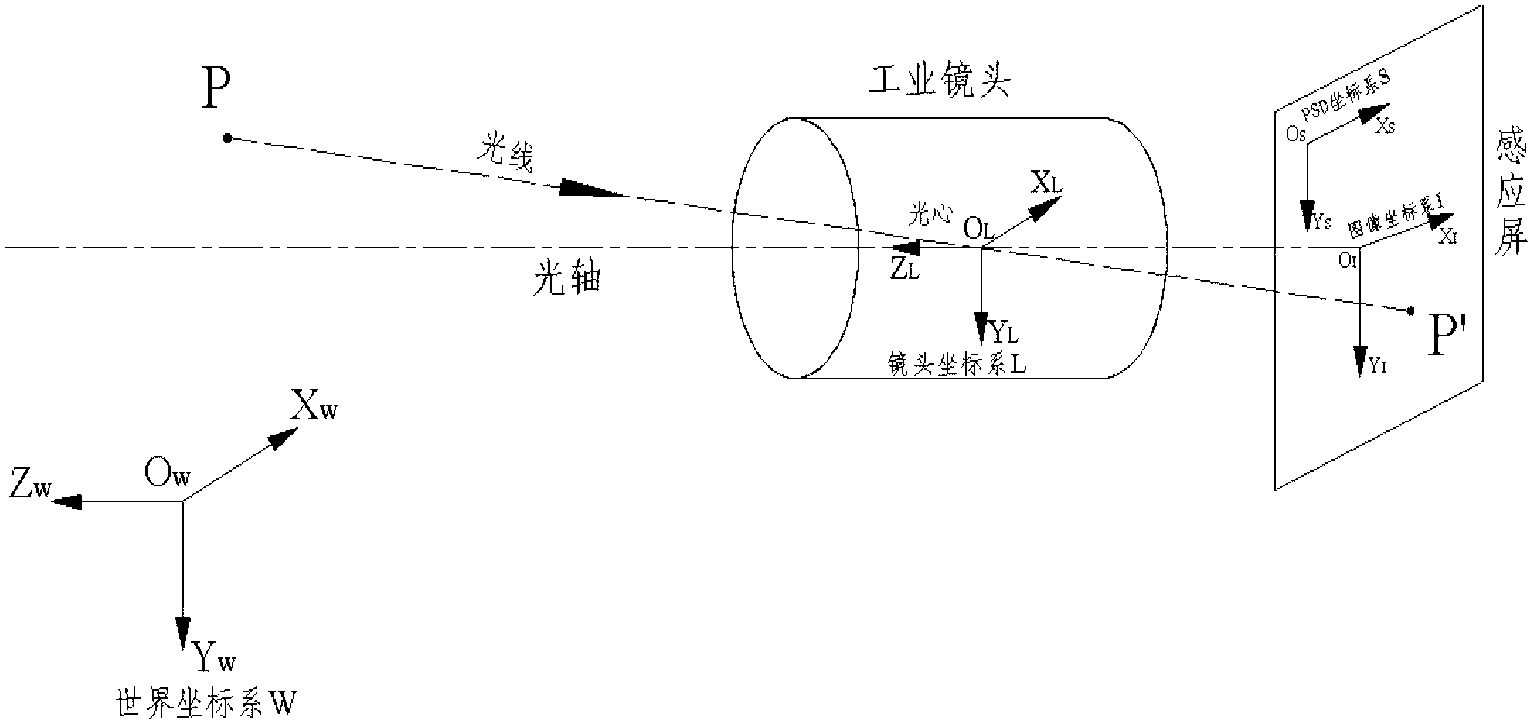

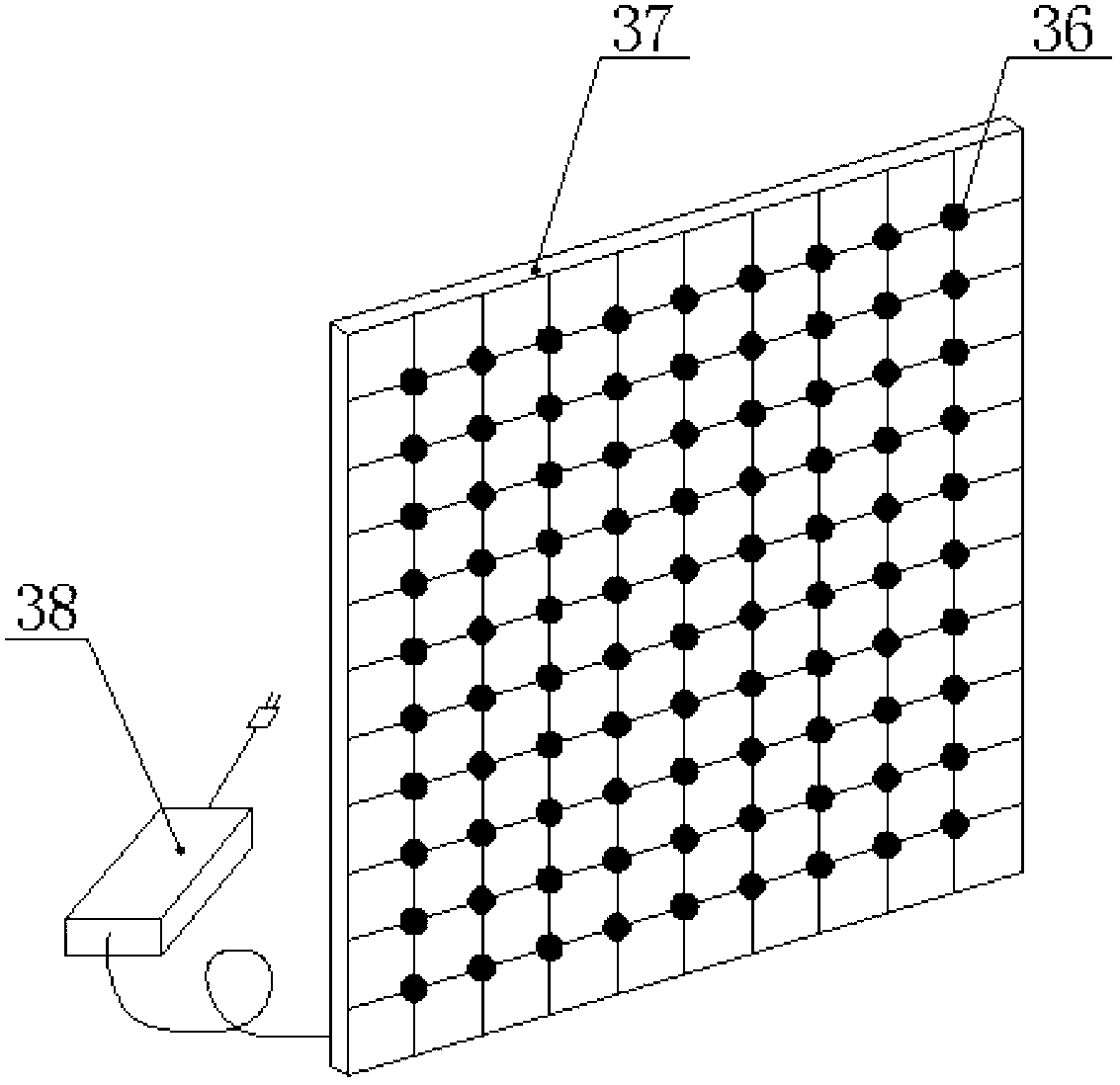

[0043] (1) The overall structure of the 2D PSD camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com