Continuous punching mould of movement bracket

A punching die and core technology, applied in the field of continuous punching die for core brackets, can solve the problems of unstable product quality, low work efficiency and high cost of use, reduce labor costs and mechanical costs, and improve work efficiency. Efficiency, the effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

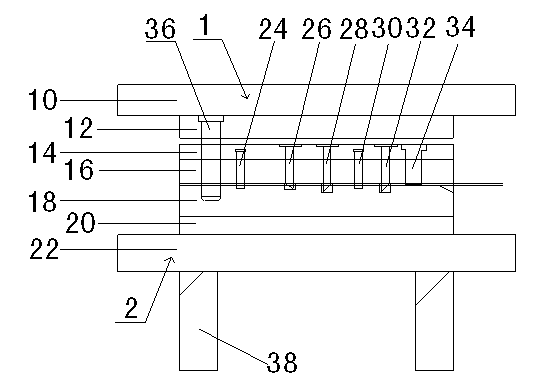

[0012] see figure 1 As shown, a continuous punching die for a core bracket of the present invention includes a corresponding upper mold 1 and a lower mold 2, wherein the upper mold 1 sequentially includes an upper mold frame plate 10, an upper mold backing plate 12, a discharge The plate backing plate 14 and the stripping plate 16, the lower mold includes the lower formwork 18, the lower mold backing plate 20 and the lower mold frame plate 22 in turn, and the special feature of the present invention is that a No. 1 punching hole is sequentially arranged on the stripping plate 16 Die 24, trimming die 26, No. 1 bending die 28, No. 2 punching die 30, No. 2 bending die 32 and forming die 34.

[0013] When making the blanking die of the present invention, preferably a guide post 36 is set in the stripper plate 16, the top of the guide post 36 extends into the upper die backing plate 12, and the bottom end of the guide post 36 extends to the below of the stripper plate 16, Holes (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com