Interlocking type gear shifting mechanism applied to gear box

A gearbox and locking technology, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of complex shifting mechanisms, many overlapping mechanisms, and difficult maintenance, and achieve safe and reliable shifting. Easy to operate, the effect of changing gears without chaotic gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

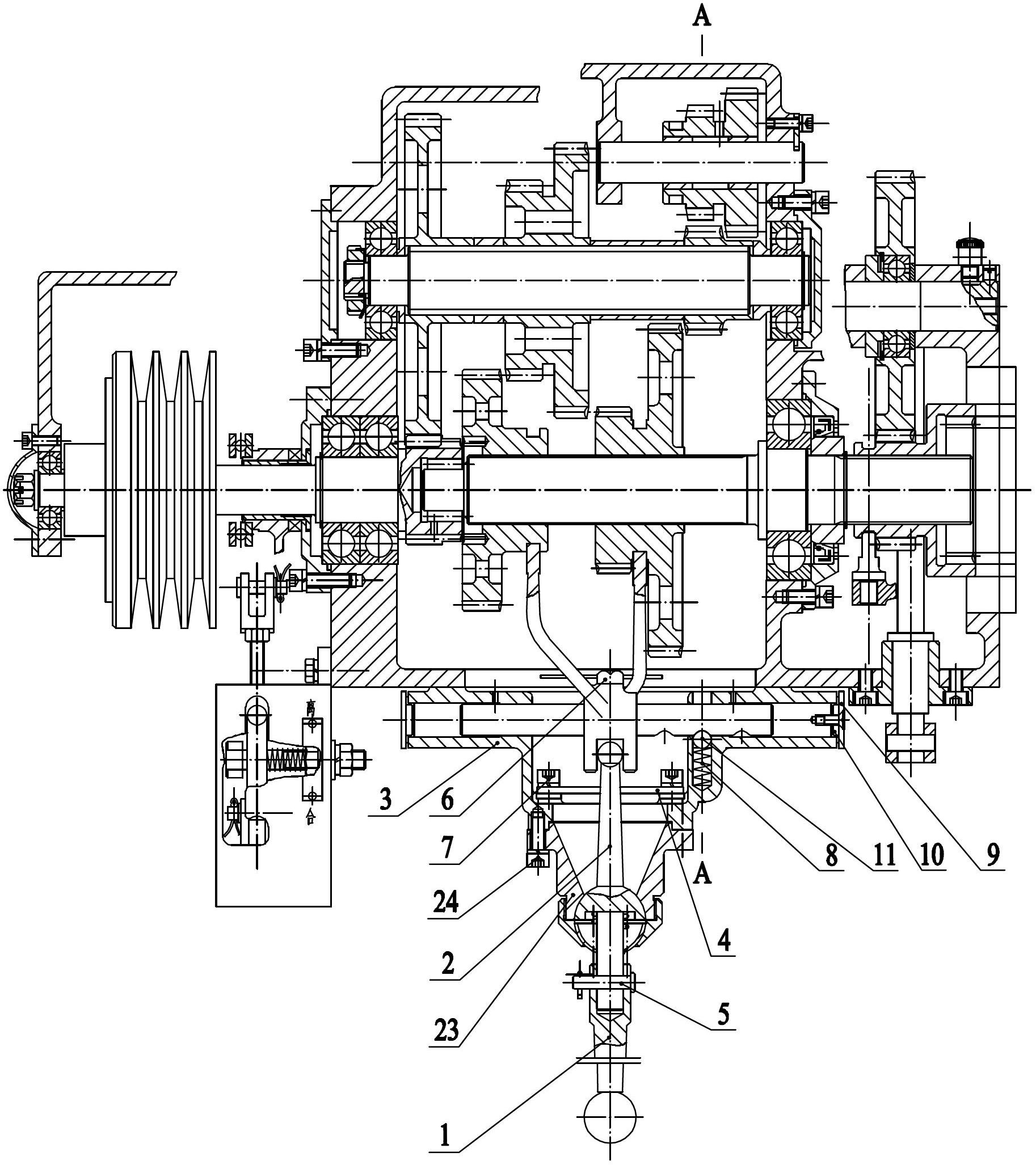

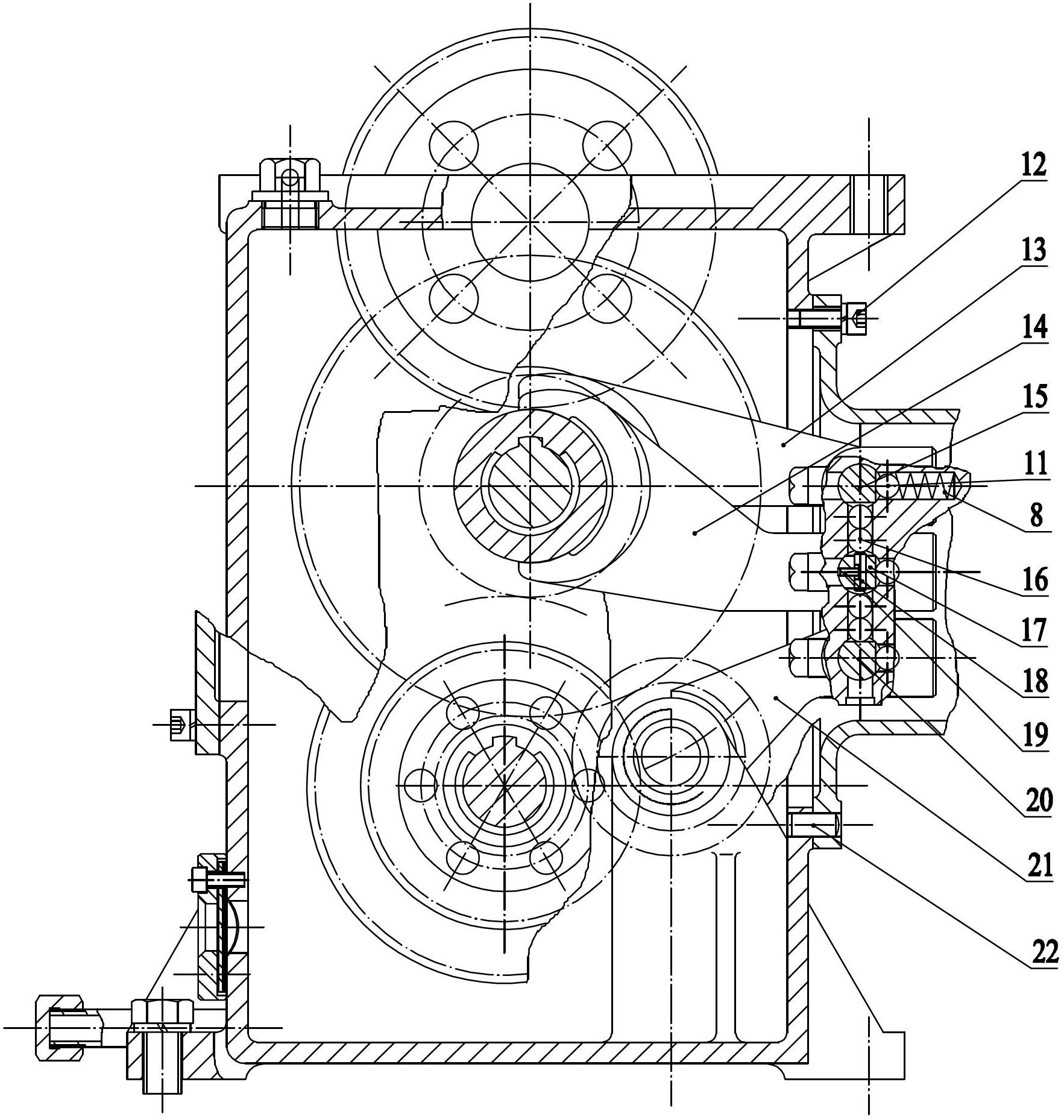

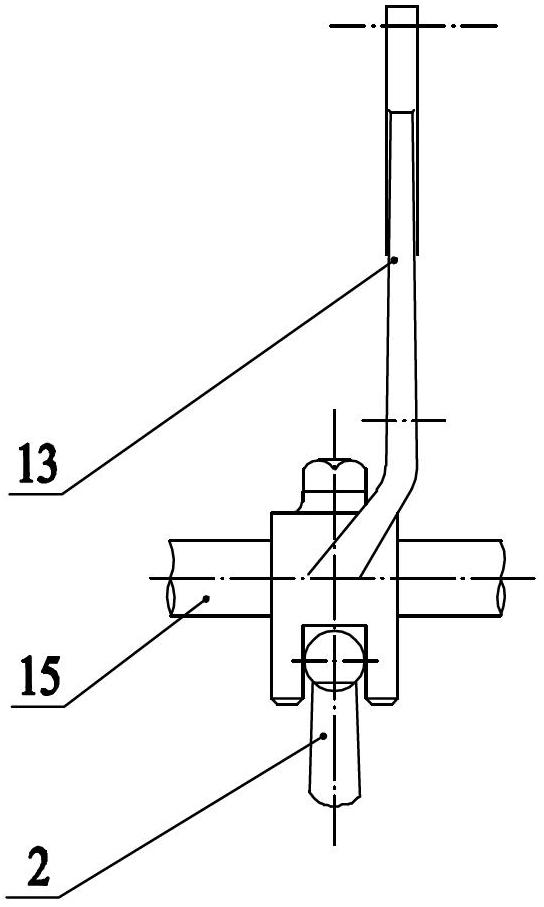

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0023] As shown in the figure: the interlocking shift mechanism in the embodiment is applied to the gearbox, and it mainly consists of an operating lever 1, a shift lever 2, a support seat 3, a limit plate 4, a pin shaft 5, a stop bolt 6, Screw 7, spring 8, cover 9, plugging 10, positioning steel ball 11, screw 12, first and third gear shift fork 13, second and fourth gear shift fork 14, first and third gear shift fork shaft 15, interlocking steel ball 16, Second and fourth gear shift fork shaft 17, stop pin 18, stop pin 19, reverse gear shift fork shaft 20, reverse shift fork 21, pin 22, shift lever seat 23 and screws 24 and other parts are composed.

[0024] Such as Figure 1~Figure 3 As shown, the support base 3 is fixed on the box body of the gearbox by screws 12 and positioned by pins 22, the shift rod 2 is installed in the shift rod seat 23, and the shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com