Friction and electromagnetism integrated brake with double disk structure

An electromagnetic brake and brake technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of easy loss of braking performance, potential safety hazards, slow response speed, etc., and achieve improved braking safety performance , Improve economy and environmental protection, and prevent the reduction of braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

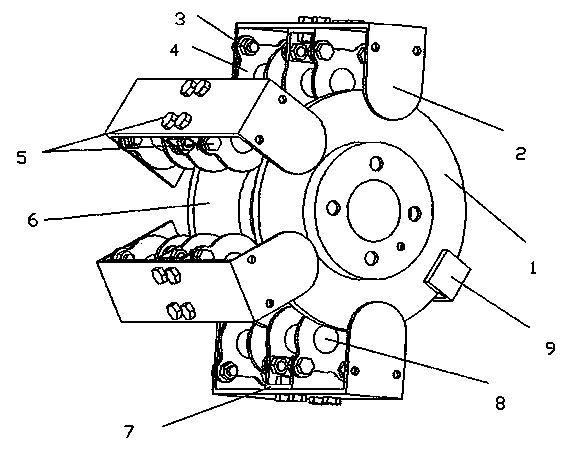

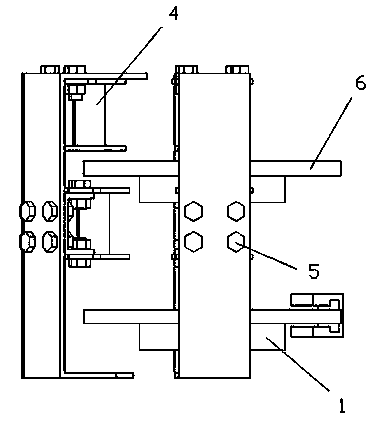

[0016] Such as figure 1 As shown, the present invention has two brake discs, which are respectively the first brake disc 1 and the second brake disc 6, and these two brake discs are used to replace the single disc brake disc of the traditional disc friction brake. , retain the original friction brake assembly (including brake blocks, brake calipers, etc.). The brake caliper 9 is arranged on the first brake disc 1 and is fixedly installed with the vehicle body. Under the control of the hydraulic brake circuit, the brake block presses against the first brake disc 1, and the first brake disc 1 generates frictional braking force.

[0017] An electromagnetic braking device is arranged on the second brake disc 6. The electromagnetic braking device includes several groups of excitation coils, each group of excitation coils is composed of two coil windings 4 and two iron cores 8, and the coil windings 4 are wound on the iron cores. 8, two coil windings 4 and two iron cores 8 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com