Method for screening alpha-ketone adipoyl-7-aminocephalosporanic acid acylase-producing bacteria

An aminocephalosporanic acid acylase and aminocephalosporanic acid technology, which is applied in the biological field, can solve problems such as low enzyme activity, and achieve the effects of simple operation, guaranteed growth and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of AKA-7-ACA and its structural analogues:

[0041] Phosphate buffer: Disodium hydrogen phosphate and sodium dihydrogen phosphate are prepared in a buffer solution in a ratio of pH 7.5.

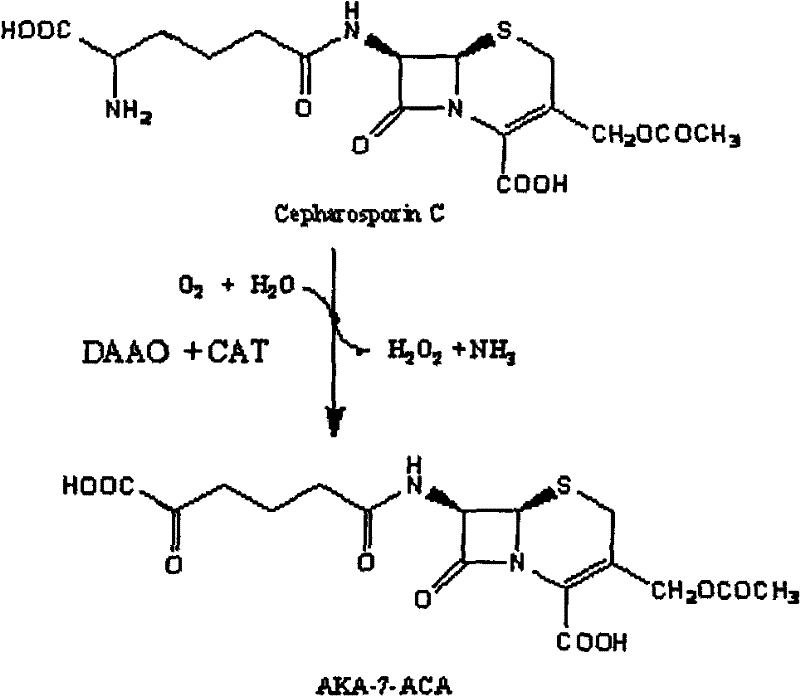

[0042] (1) Preparation of AKA-7-ACA

[0043] 100ml of 2% CPC is dissolved in a phosphate buffer with a concentration of 0.1mol / L and a pH of 7.5, put it into the reactor, and add 3ml of 40U DAAO and 3ml of 2000U CAT. Pure oxygen is introduced during the reaction with constant stirring. The temperature was controlled at 28°C, and the reaction solution was collected by centrifugation after 2h, and the reaction solution was concentrated and crystallized to obtain AKA-7-ACA.

[0044]

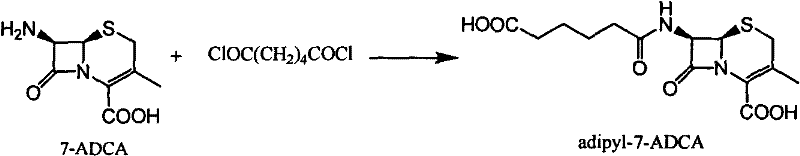

[0045] (2) Preparation of Adipoyl-7-ADCA

[0046] 5~10mL adipoyl chloride (adipoyl chloride) was slowly dripped into 5g of 7-ADCA alkaline solution with a pH value of 8~9, adding baking soda solid while stirring, keeping the pH unchanged, and collecting the reaction after 2h by centrifugation The prod...

Embodiment 2

[0071] 1. Preparation of AKA-7-ACA and its structural analogues:

[0072] Phosphate buffer: Disodium hydrogen phosphate and sodium dihydrogen phosphate are prepared in a buffer solution in a ratio of pH 7.5.

[0073] (1) Preparation of AKA-7-ACA

[0074] 100ml of 2% CPC is dissolved in a phosphate buffer with a concentration of 0.1mol / L and a pH of 7.5, put it into the reactor, and add 3ml of 40U DAAO and 3ml of 2000U CAT. Pure oxygen is introduced during the reaction with constant stirring. The temperature was controlled at 27-29°C, and the reaction solution was collected by centrifugation after 2h, and the reaction solution was concentrated and crystallized to obtain AKA-7-ACA.

[0075]

[0076] (2) Preparation of keto-7-ADCA

[0077] 100ml of 2% deacetylated CPC is dissolved in a phosphate buffer with a concentration of 0.1mol / L and a pH of 7.5, put into the reactor, and 2ml of 40U DAAO and 4ml of 2000U CAT are added. Pure oxygen is introduced during the reaction. With constant sti...

Embodiment 3

[0101] 1. Preparation of AKA-7-ACA and its structural analogues:

[0102] Phosphate buffer: Disodium hydrogen phosphate and sodium dihydrogen phosphate are prepared in a buffer solution in a ratio of pH 7.5.

[0103] (1) Preparation of AKA-7-ACA

[0104] 100ml of 2% CPC is dissolved in a phosphate buffer with a concentration of 0.2mol / L and a pH of 7.5, put into the reactor, 4ml of 40U DAAO and 2ml of 2000U CAT are added, and pure oxygen is introduced during the reaction with constant stirring , The temperature was controlled at 27-29°C, the reaction solution was collected by centrifugation after 2.5h, and the reaction solution was concentrated and crystallized to obtain AKA-7-ACA.

[0105]

[0106] (2) Preparation of Adipoyl-7-ADCA

[0107] 5~10mL adipoyl chloride (adipoyl chloride) was slowly dropped into 5g of 7-ADCA alkaline solution with pH 8~9, and baking soda solid was added while stirring, keeping the pH constant, and the reaction product was collected by centrifugation after 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com