Thermal power plant, in particular solar thermal power plant

A technology of solar energy and thermal power plants, which is applied in the fields of solar thermal power plant equipment and gas turbine devices, and can solve the problems of scarcity of natural water resources, poor cooling effect, and reduced power plant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

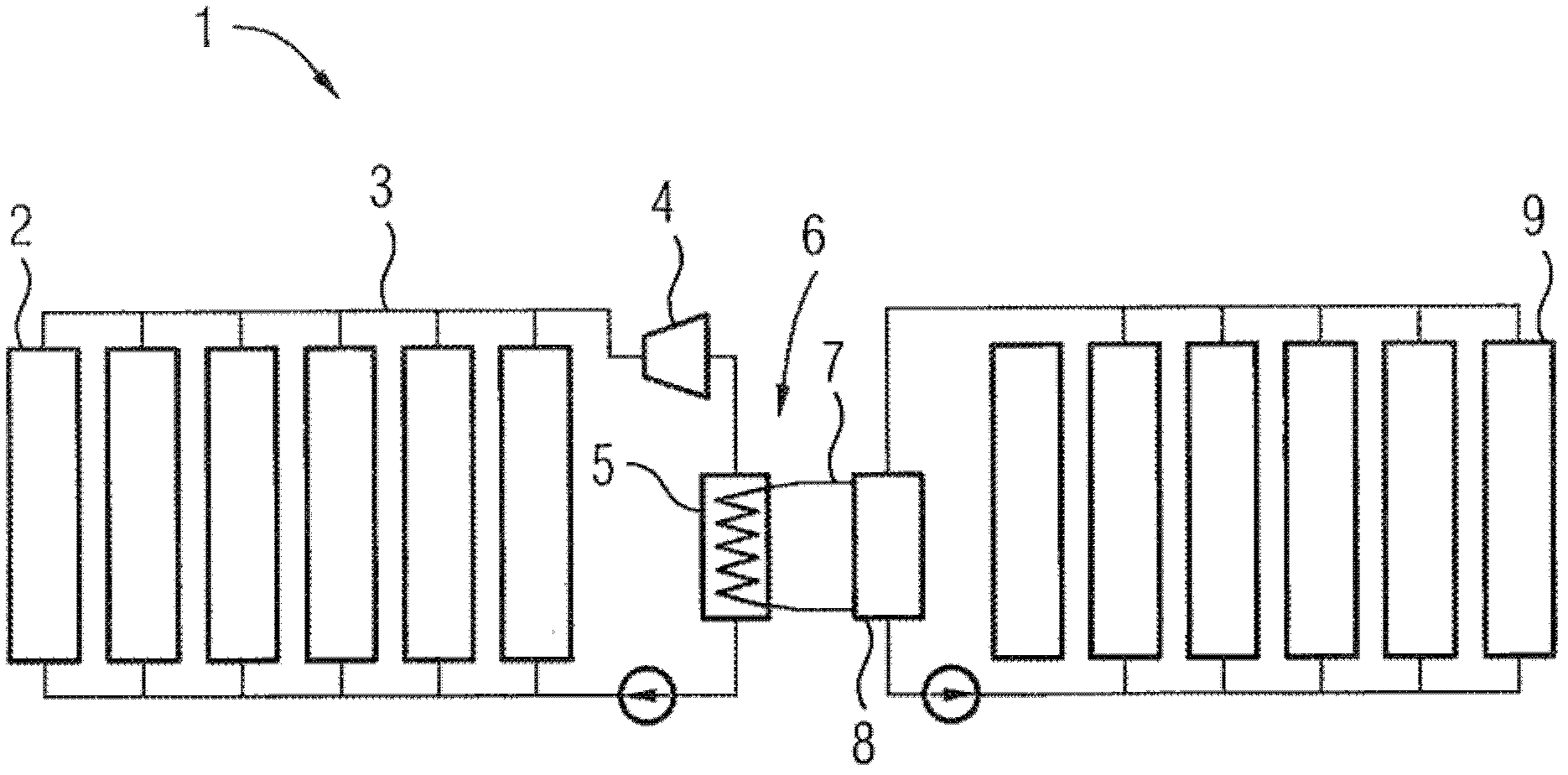

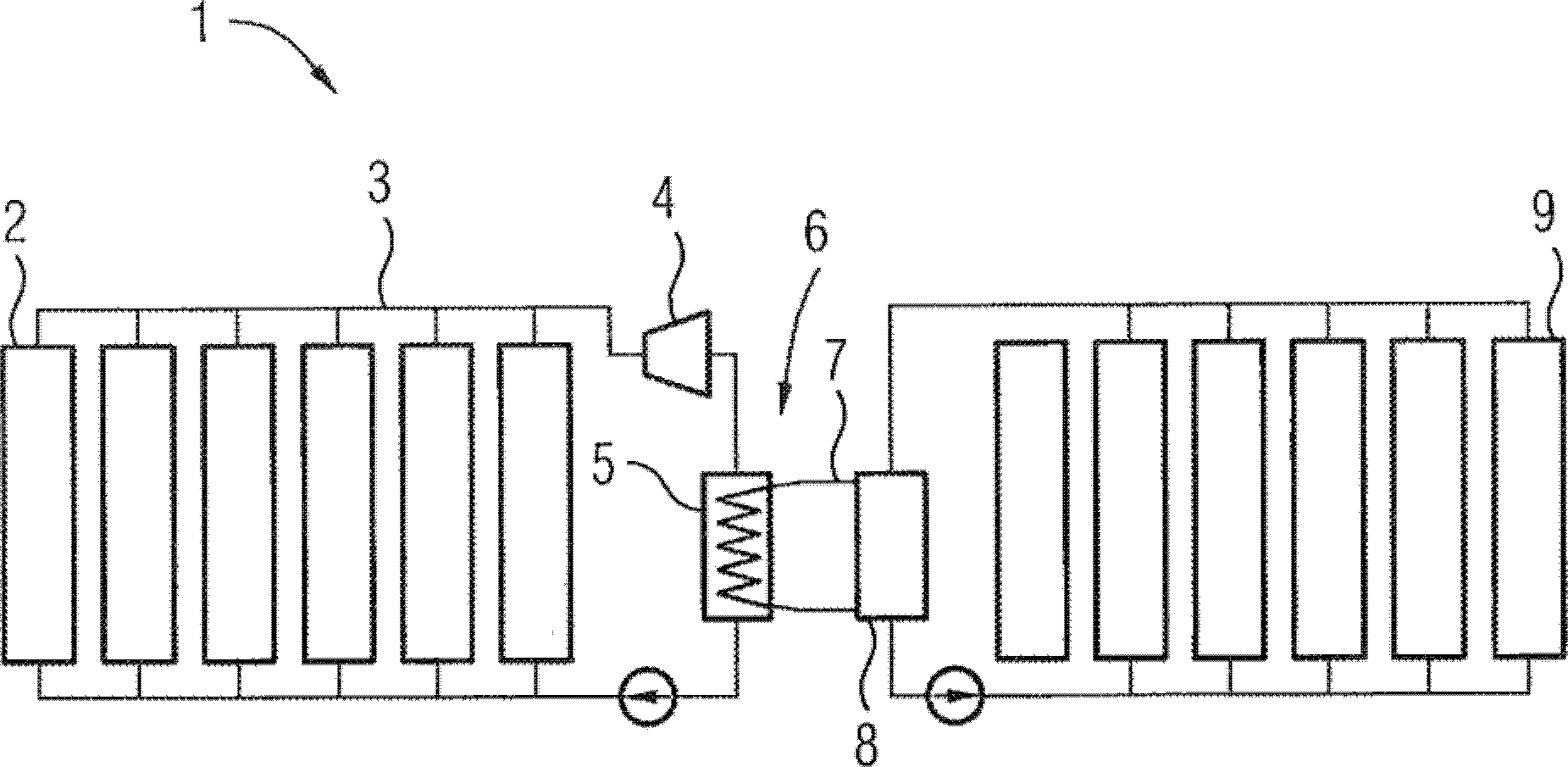

[0017] The drawing shows an exemplary embodiment of a solar thermal plant installation 1 according to the invention. The solar thermal power plant installation firstly comprises a solar collector 2 for power plant operation, which is here designed as a parabolic trough. The solar heat concentrated by the parabolic trough in the central area thus directly heats and vaporizes the medium circulating in the circuit 3 via said parabolic trough, wherein the steam produced is converted into electrical energy in the turbine 4 . The medium is liquefied again in the condenser 5 , wherein the condenser is cooled by a solar-operated cooling device 6 . The liquefied medium is then vaporized again, thus closing circuit 3 . It should be noted here that, obviously, only the schematic diagrams of the most important components are involved here; the principles of thermal power plant equipment are well known and need not be explained in detail here.

[0018] Alternatively, in addition to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com