Tissue paper and method of manufacturing tissue paper

A manufacturing method and technology of tissue paper, applied in the direction of tissue/absorbent paper, skin care preparations, paper, etc., can solve the problems of low strength, slow water absorption of moisturizing tissue paper, sticky feeling of users, etc., and achieve pull The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

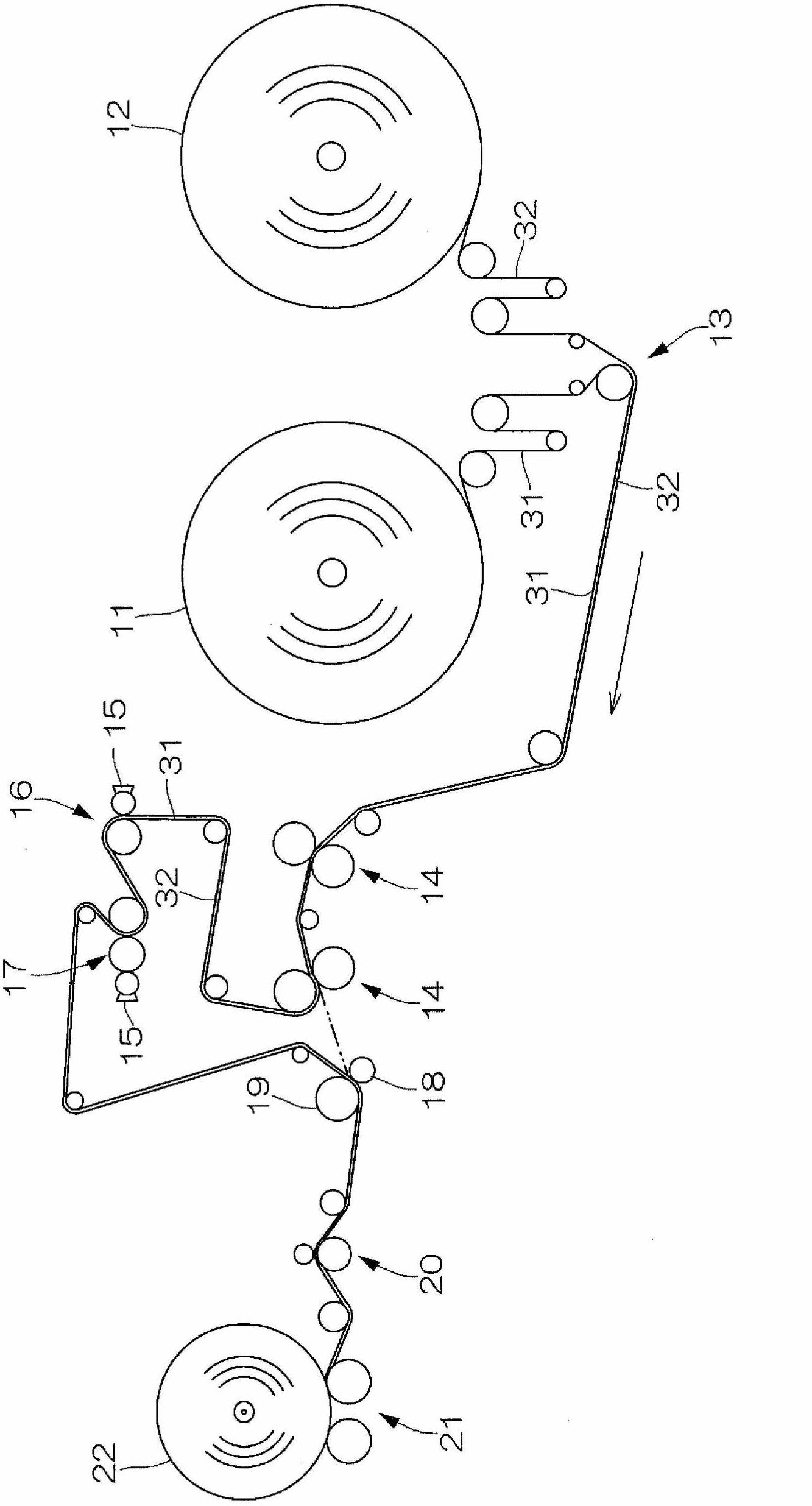

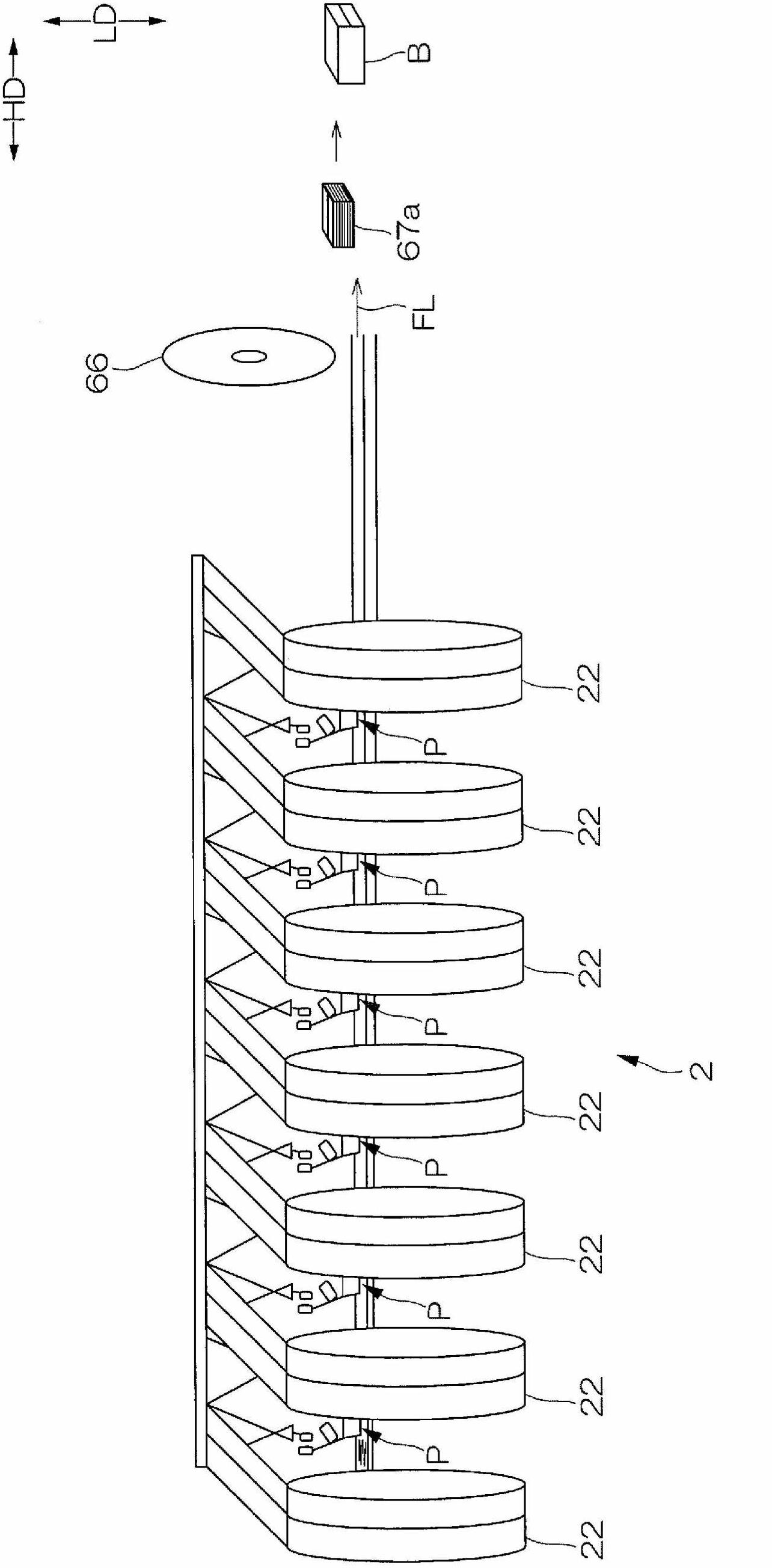

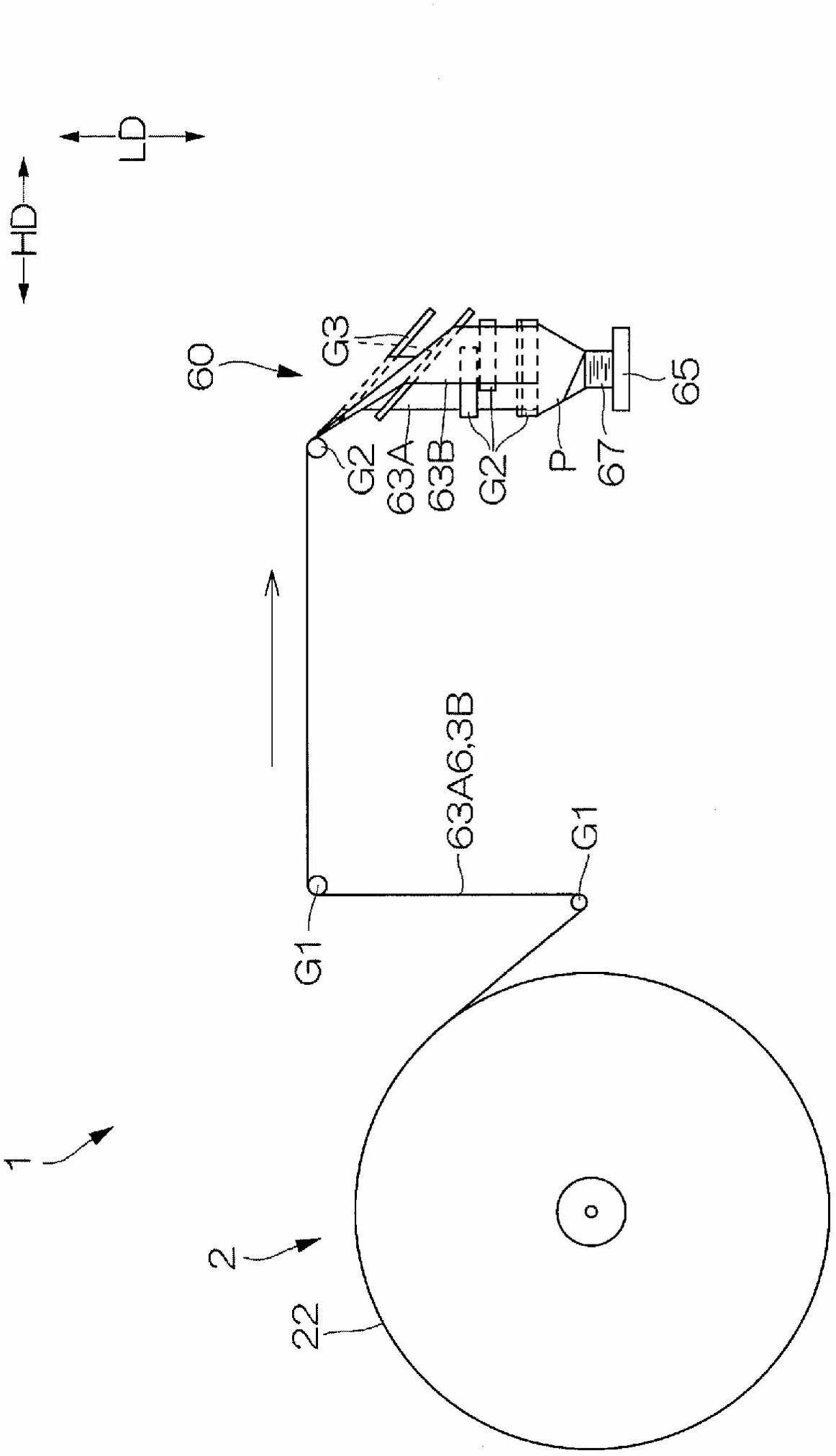

Method used

Image

Examples

Embodiment

[0124] In order to confirm the effect of this invention, the evaluation of the paper quality of a product was performed about the Example of this invention and a comparative example, and the result is shown in Table 1. Comparative Example 1 is a common non-moisturizing tissue paper, Comparative Examples 2, 5, and 6 are moisturizing tissue papers, and Comparative Examples 7 and 8 are non-moisturizing high-grade tissue papers with high basis weight and paper thickness. In Comparative Example 3, the oily component in the chemical solution was more than the predetermined tissue paper sample, and in Comparative Example 4, the organic silicon content in the chemical liquid was more than the predetermined tissue paper sample.

[0125] The measurement methods of basis weight, paper thickness, tensile strength, elongation, softness, water absorption, and water content are as described in the detailed description.

[0126] While evaluating the quality of the paper, for Examples 1 and 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com