Six-degree-of-freedom parallel and oscillating guide bar mechanism combined knee-replacing prosthesis abrasion tester

A knee joint replacement and swing guide rod technology, applied in the direction of testing wear resistance, etc., can solve the problem of unsatisfactory use of the knee prosthesis, and achieve the effects of easy control, low wear and low friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

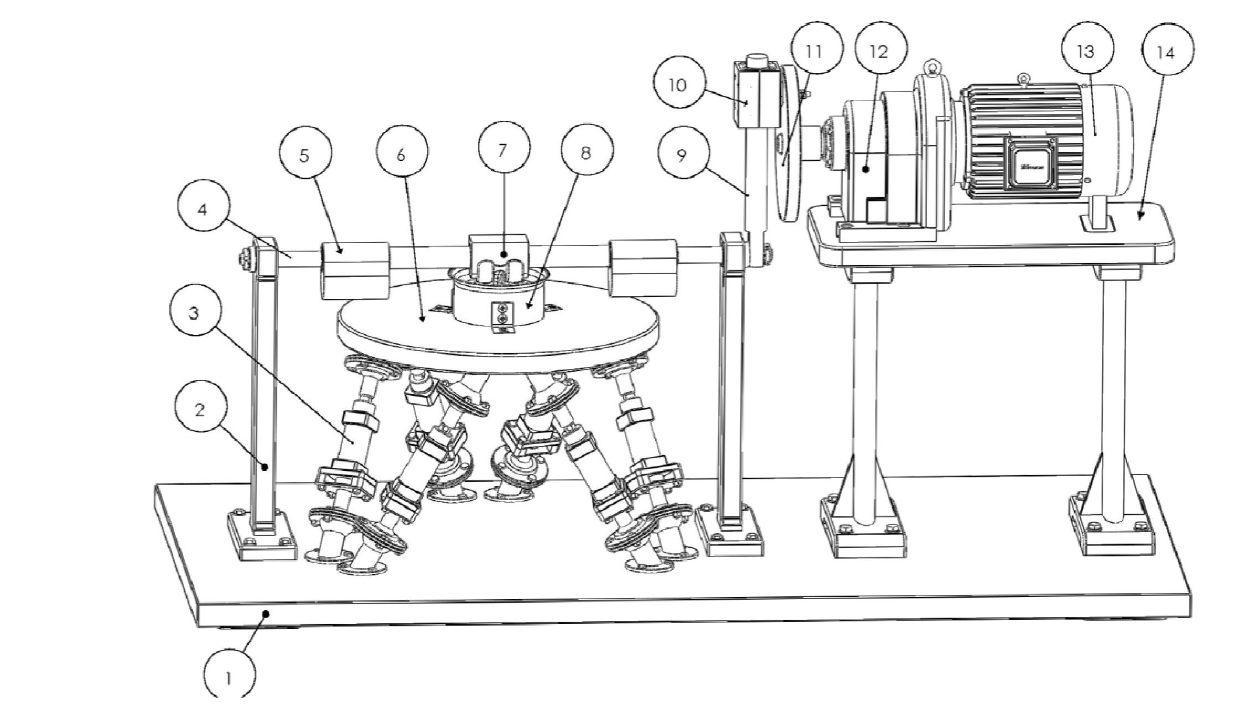

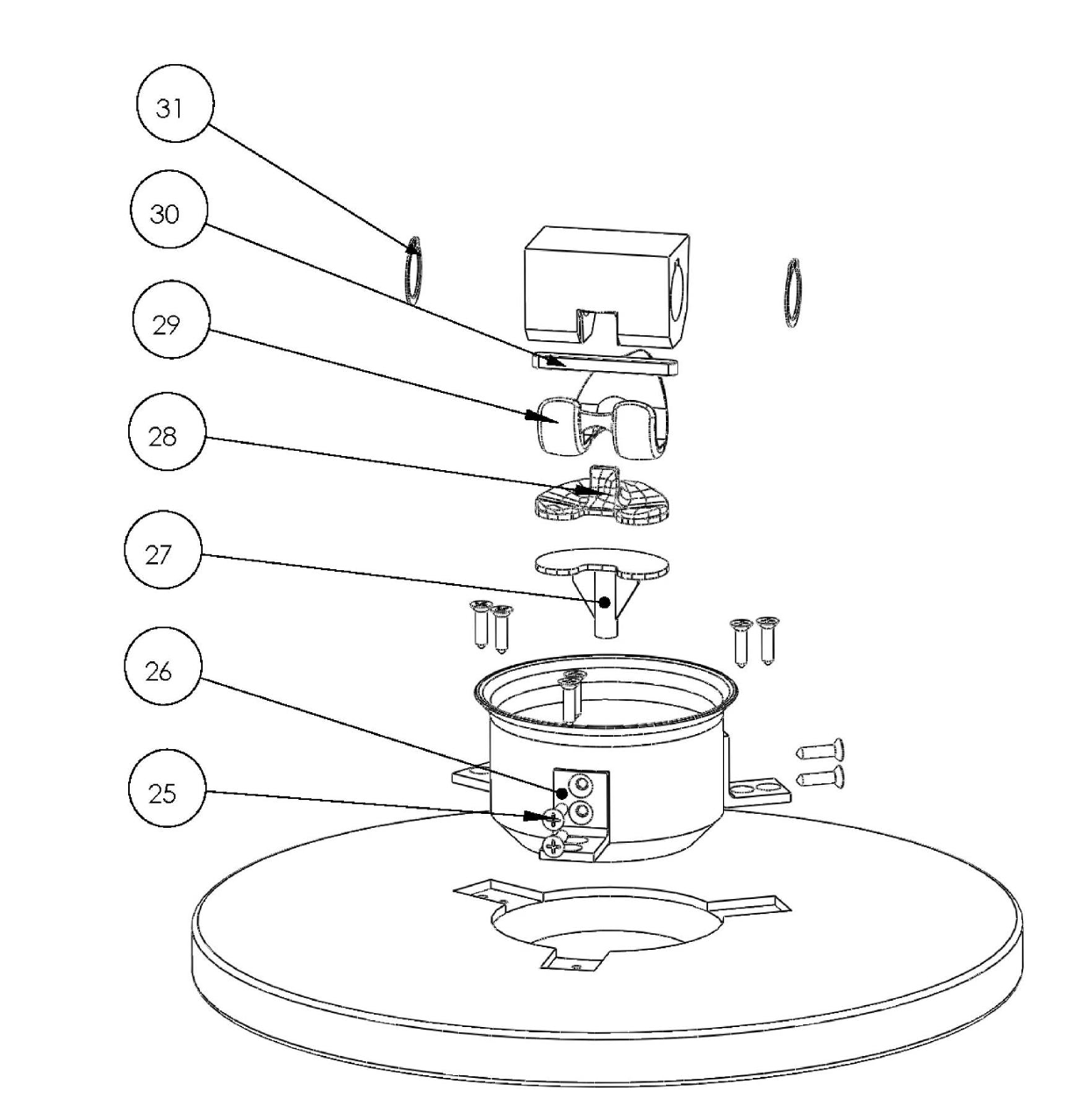

[0040] Such as figure 1 Shown, the present invention is made up of right part, left part and base 1, and right part is the driving device of wear machine, on the right side of whole device, and left part is the actuator of wear machine, on the left side of whole device. The two are connected through a swing guide rod mechanism, so that the rotary motion of the motor 13 is converted into the swing and flexion motion of the long axis 4 and the femoral prosthesis 29 . Both the right part and the left part are installed and fixed on the base 1.

[0041] For the actuator of the wear machine, the specific description is as follows:

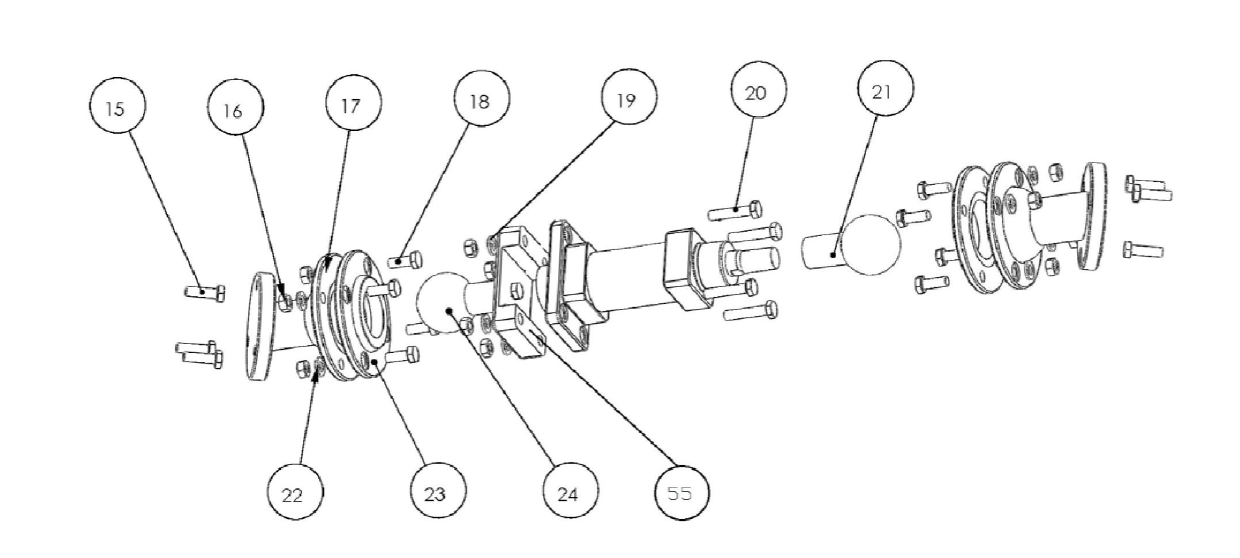

[0042] The spherical hinge base 17 is connected to the groove in the base 1 through the hex head bolt 15, and the installation requirements are as follows: figure 1 As shown, two adjacent ball joint bases 17 located farther away are relatively installed. And when the spherical hinge base 17 is designed, the angle between its axis and the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com