Positioning support for dowel bars at concrete pavement joints

A technology for positioning brackets and dowel bars, applied in the direction of road construction reinforcements, etc., to achieve the effects of avoiding poor stability, reasonable design, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

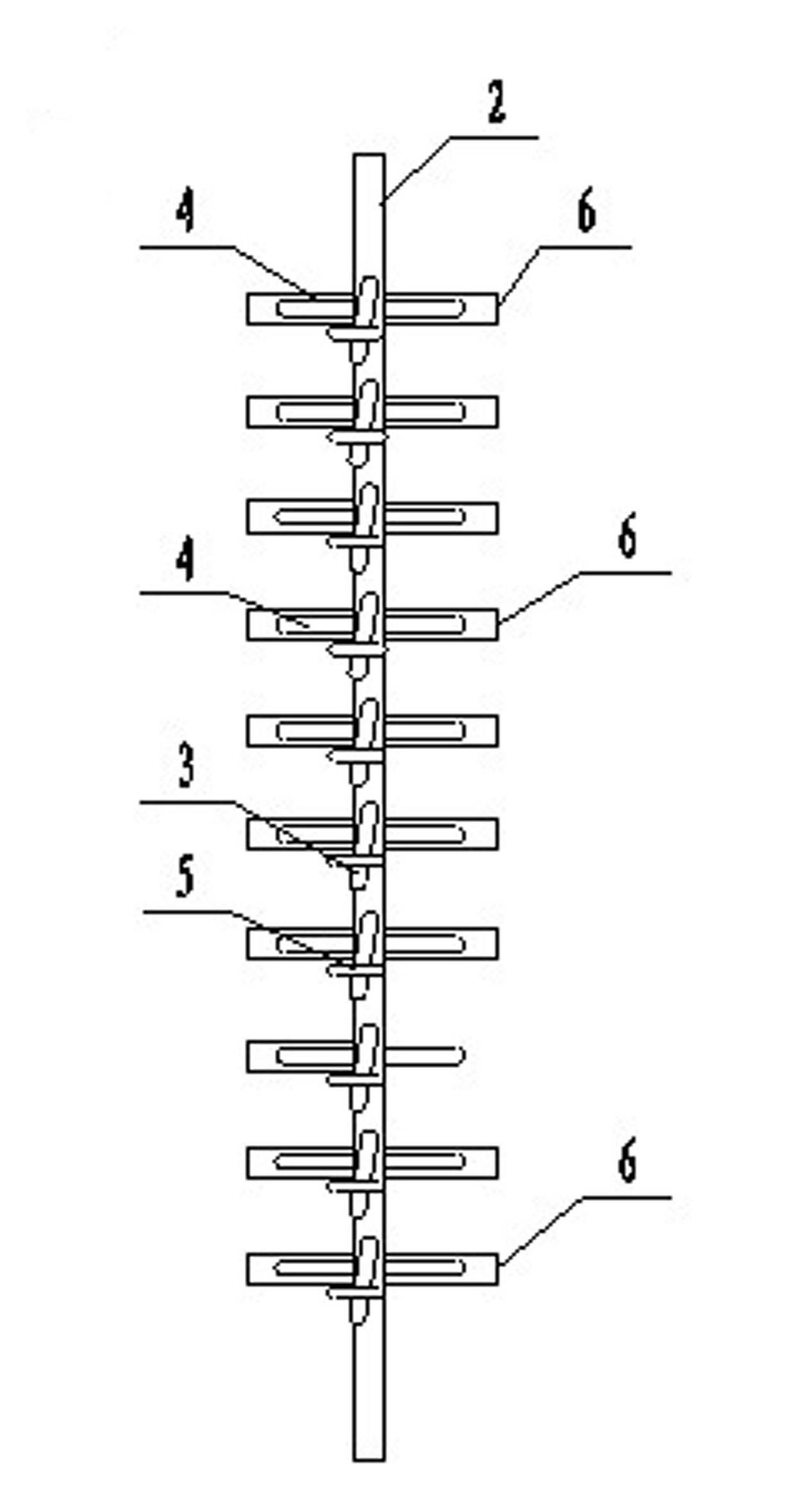

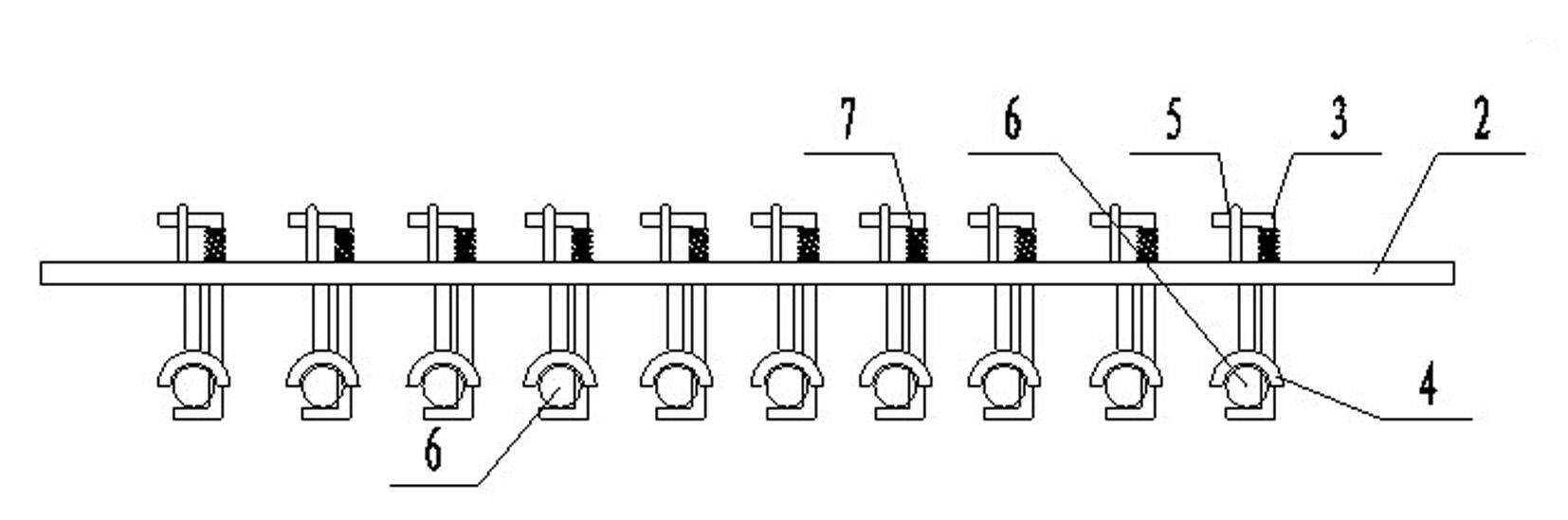

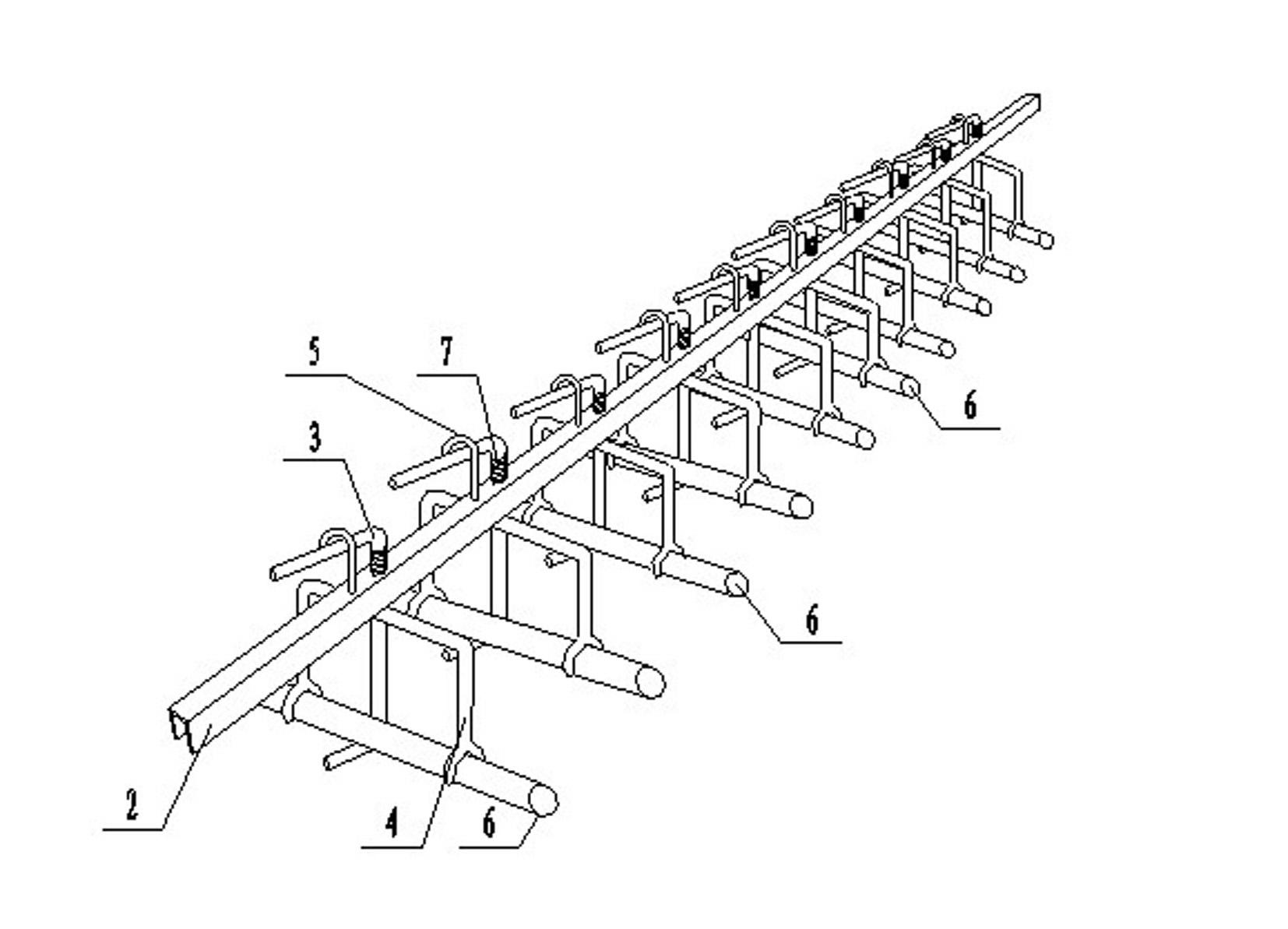

[0025] A concrete pavement joint dowel positioning bracket, such as figure 1 , 2 , 3, including positioning main rods 2 (such as Figure 4 shown), through the fixed rod 3 arranged in each positioning hole, the bracket leg 4 installed under the positioning main rod and on the side of the fixed rod 3, and the lower end is fixed above the positioning main rod 2 and the hook head at the upper end is close to the fixed rod 3 The inverted hook 5 (eg Figure 7 shown); in specific implementation, such as Figure 4 As shown, channel steel can be used for the positioning main rod, and the type of channel steel can be adjusted according to the construction situation. The length L of the positioning main rod is the length of the joint of the concrete plate + 60cm (that is, the two ends of the positioning main rod are increased by 30cm, which is convenient for workers to hold and place). Set up positioning holes on the channel steel according to the number of dowel bars and the designed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com