Solid distillation method for making wine and solid distillation device thereof

A solid-state distillation and steam technology, which is applied in the solid-state distillation unit and the field of solid-state distillation of winemaking, can solve the problems of affecting the yield and quality of wine, uneven steam penetration, and missing tails. Guaranteed quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

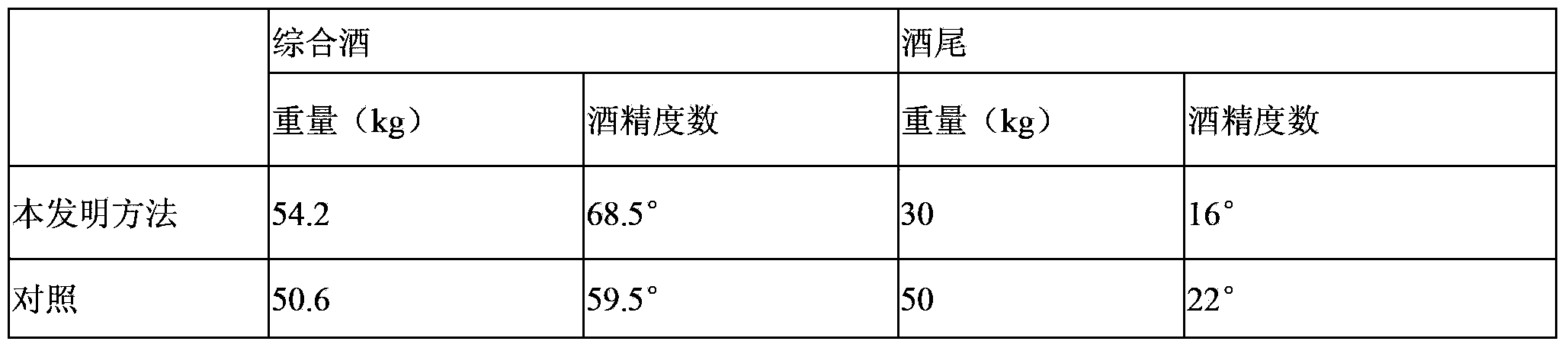

[0023]The same distilled grains fermented for 60 days were used as the research material, and the distillation research was carried out under the same steam condition with a vapor pressure of 0.03Mpa.

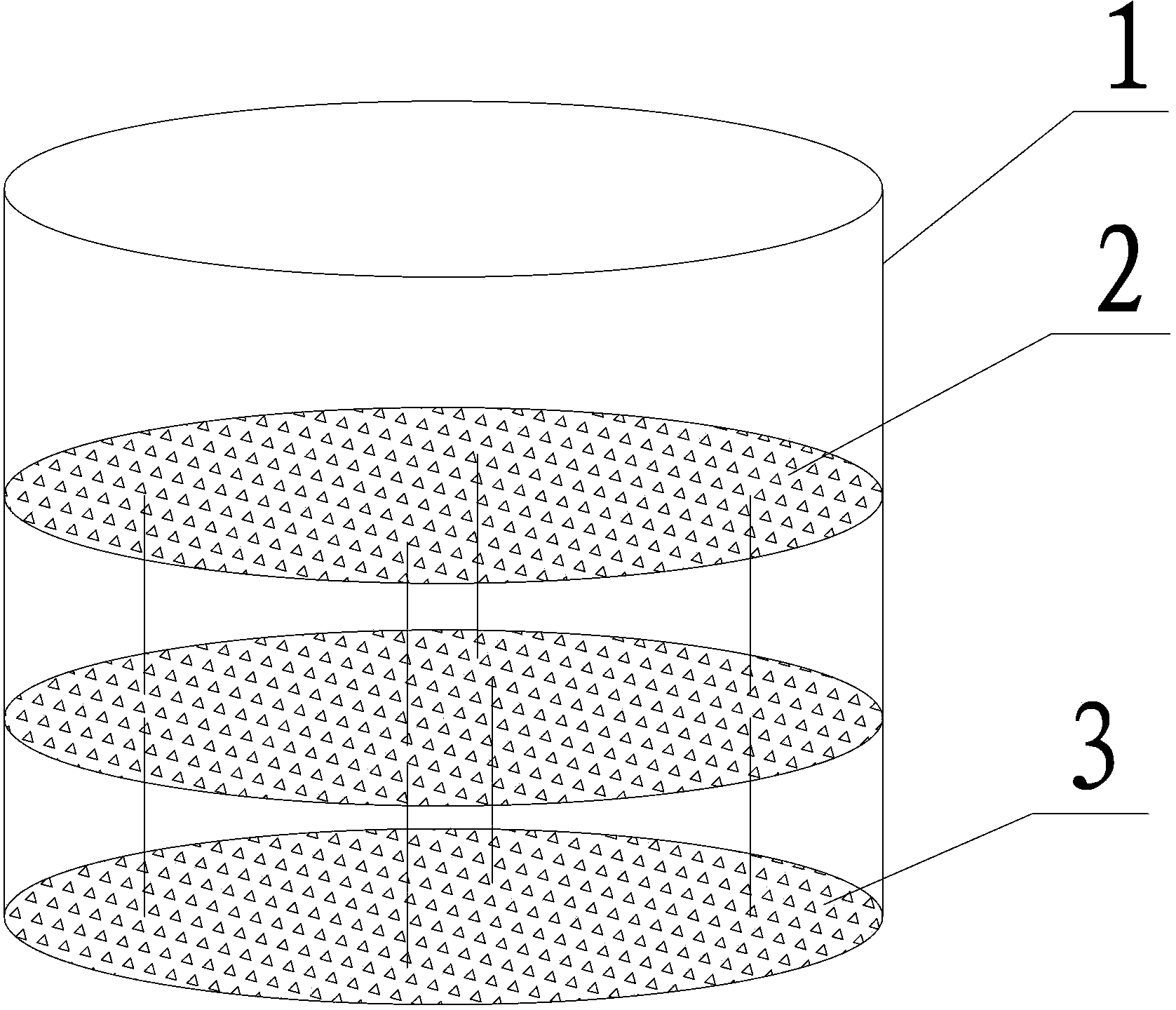

[0024] Adopt the distillation method of the present invention, take the solid-state distillation device of the present invention as the distillation device, and the capacity of the retort bucket 1 is 2.00m3. During the upper retort process, turn on steam in the bottom pot of retort bucket 1, and spread a layer of cooked bran evenly on the bottom hole plate 3 at the same time, with a thickness of 0.5-1cm, and then evenly spread the fermented grains on the hole bottom plate 3; Place supporting orifice plates 4 layer by layer on the bottom plate 3, and in the same manner spread cooked bran and unstrained grains successively and evenly on each support orifice plate 4, the height of each layer of unstrained grains is 25cm, place four sets of support orifice plates, There are 5 layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com