Scrapper machine

A technology of scraper machine and lug plate, which is applied in the field of coal mine transportation, can solve the problems of complex structure and time-consuming, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

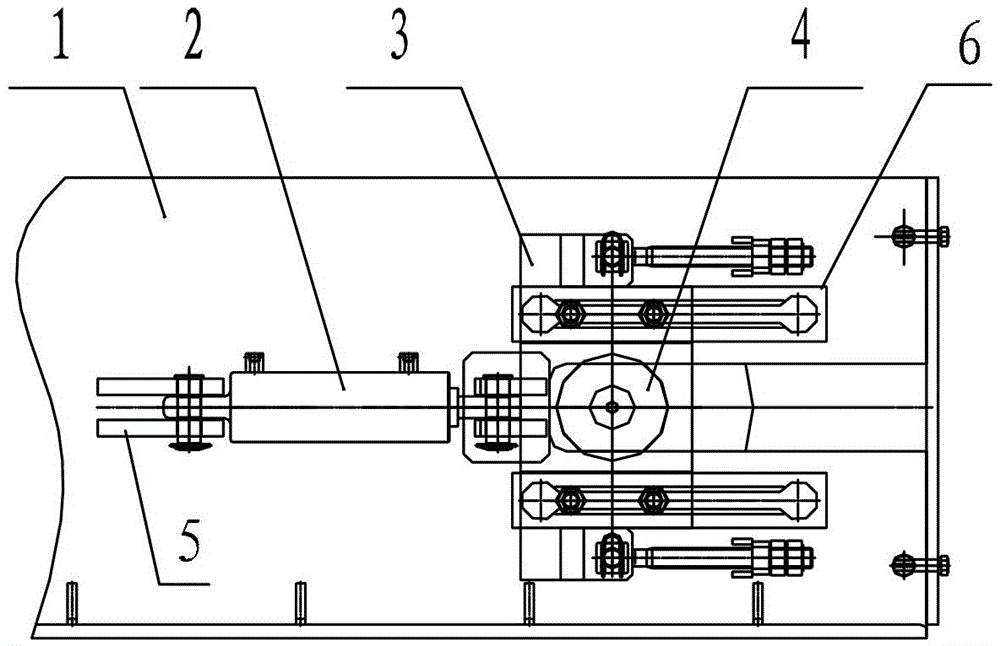

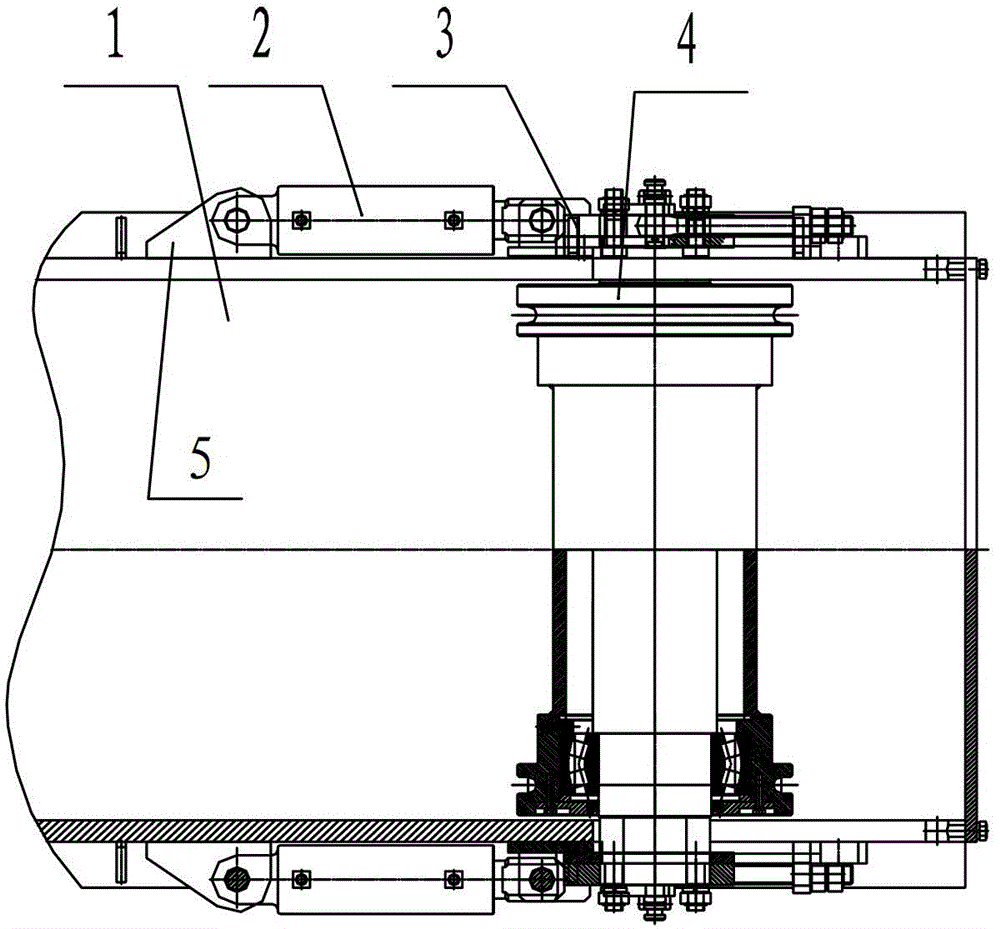

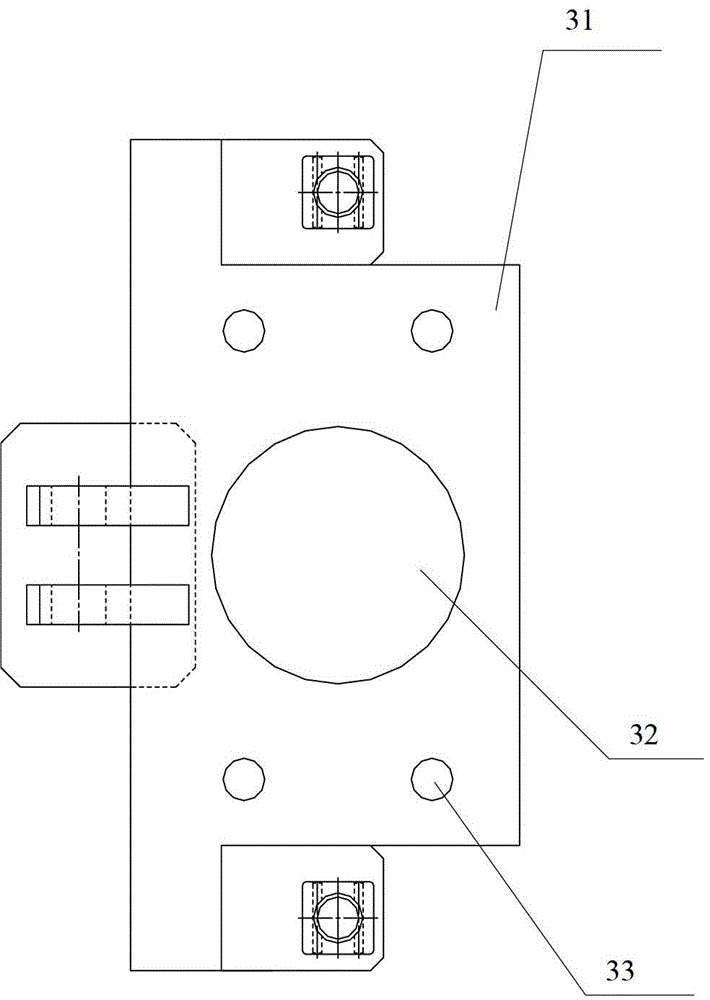

[0019] figure 1 The front view of the partial structure of the scraper machine provided by the embodiment of the present invention, figure 2 for figure 1 According to the top view, the embodiment of the present invention provides a scraper machine, including a tail frame 1 and a tail wheel 4, the tail frame 1 is provided with an open slot, and the tail wheel 4 passes through the open slot and is fixed on the tail frame 1, wherein the scraper machine also includes a linear drive 2 and a push seat 3 fixedly arranged on the tail frame, one end of the push seat 3 is fixedly connected to the linear drive 2, and the body of the push seat 3 is connected to the tail wheel 4 Fixedly connected, it is used to push the tail wheel 4 to move relative to the tail frame 1 under the drive of the linear driver 2; the push seat 3 is provided with a guide rail facing the side of the tail frame 1, and the tail frame 1 is provided with a guide groove 6. The guide groove 6 cooperates with the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com