Coating process for vehicle armrest

A technology of automobile handrails and craftsmanship, which is applied in special positions of vehicles, vehicle parts, transportation and packaging, etc., can solve the problems of long research and development cycle, long working hours, high cost, etc. The effect of reducing the investment in foaming equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

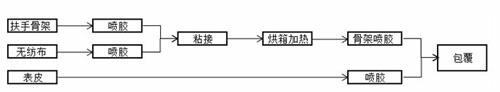

[0016] see figure 1 , the invention provides the cladding process of automobile handrail, comprises the following operation steps:

[0017] a. Spray glue on the surface of the car armrest skeleton and the surface of the non-woven fabric;

[0018] b. Bond the non-woven fabric to the surface of the car armrest skeleton, and then trim the edge of the non-woven fabric with a utility knife;

[0019] c. Put the car armrest skeleton bonded with non-woven fabric into the oven for baking and heating, and then spray glue on the surface after taking it out;

[0020] d. Spray glue on the inside of the epidermis;

[0021] e. The epidermis is coated on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com