Tensioning tool for simultaneously manufacturing prestressed concrete pipe piles

A technology of simultaneous manufacturing of concrete pipe piles, applied in the direction of reinforcement molding, etc., can solve the problems that the area of the tensioning tool cannot be sealed, affects the disassembly of the tensioning tool, and low production efficiency, and achieves convenient and quick disassembly of the tensioning tool and simple structure , the effect of a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

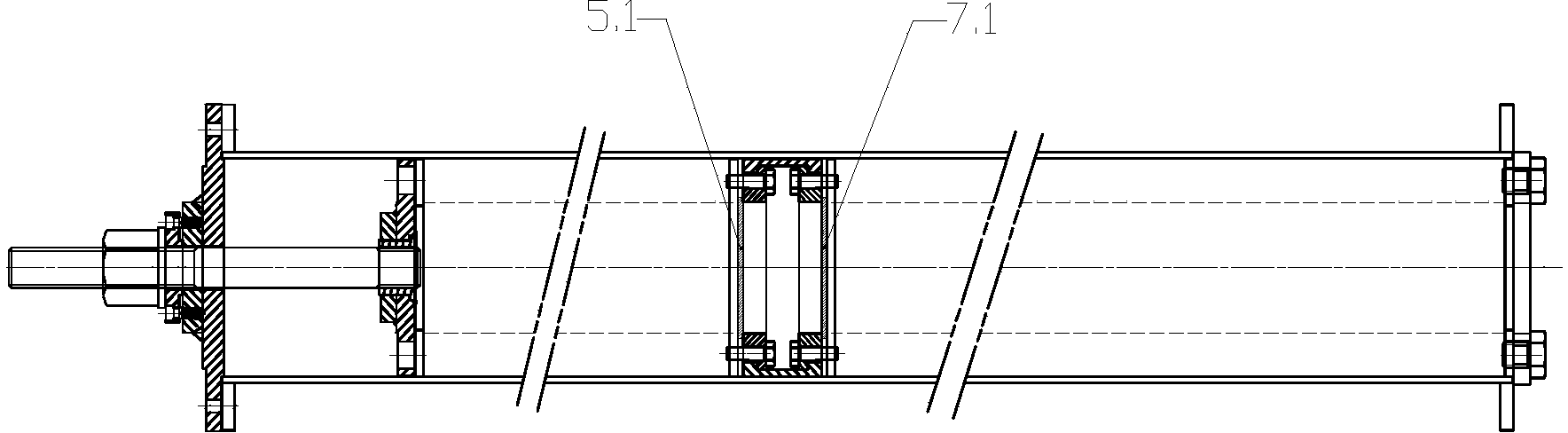

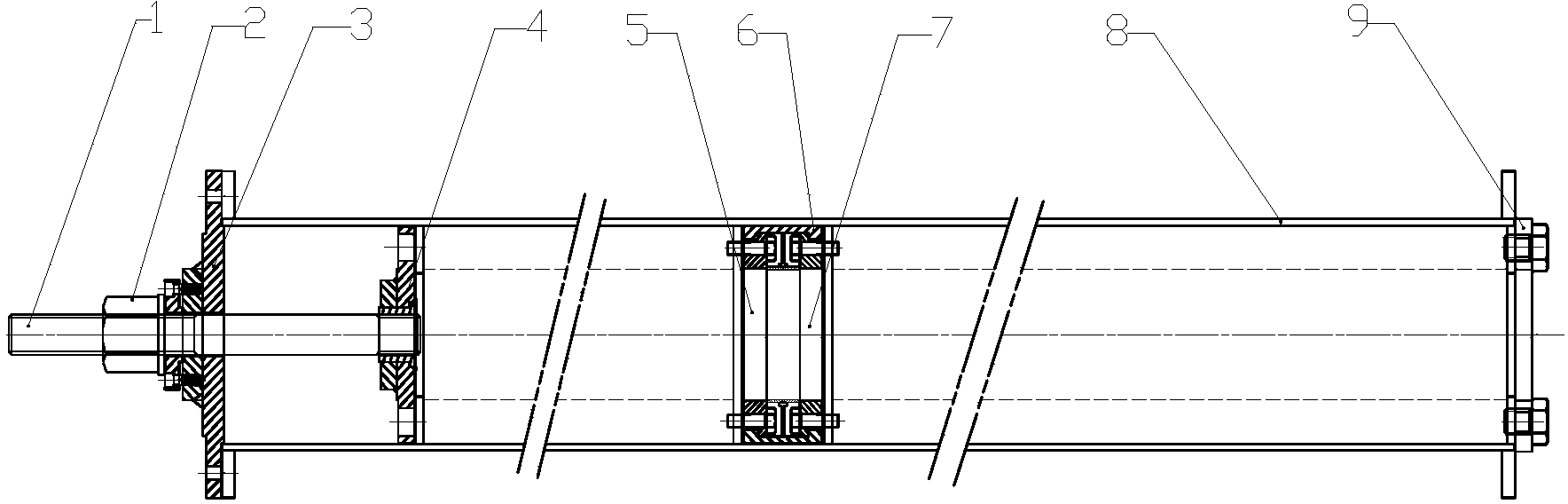

[0015] as attached Figure 1~6 As shown, a tensioning tool for manufacturing multiple prestressed concrete pipe piles at the same time includes fixing plates 9 and locking plates 3 respectively arranged at both ends of the pipe pile mold 8, and the fixing plates 9 and locking plates 3 are both The flanges at both ends of the pipe pile mold 8 are bolted to the pipe pile mold 8, and the locking plate 3 is provided with a screw 1 for tensioning, and the screw 1 passes through the lock through the through hole in the middle of the locking plate 3. Tightening plate 3, a part of the screw 1 is located outside the pipe pile mold 8, and a part is located in the pipe pile mold 8, the axis of the screw 1 is coaxial with the axis of the pipe pile mold 8, and the screw 1 is provided with a screw for locking the screw. 1 lock nut 2, when locked, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com