Drawing machine

A technology of drawing machine and frame, applied in the field of drawing machine, can solve the problems of poor stability of drawing operation and achieve the effect of smooth drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

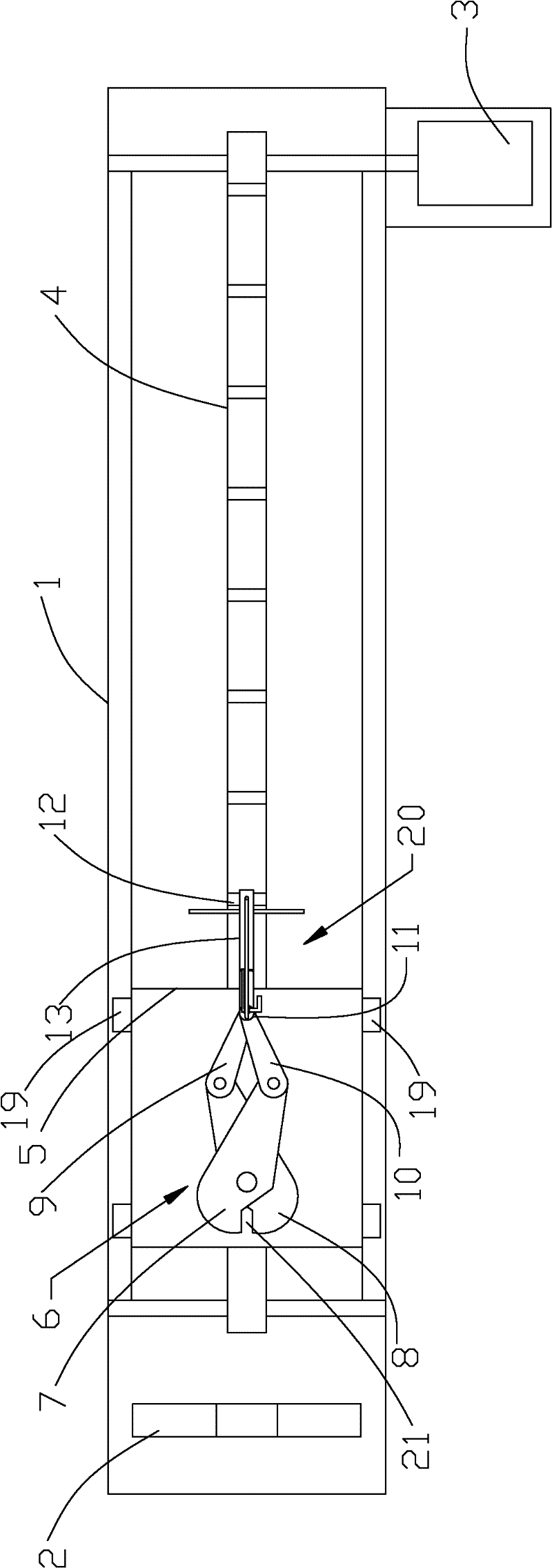

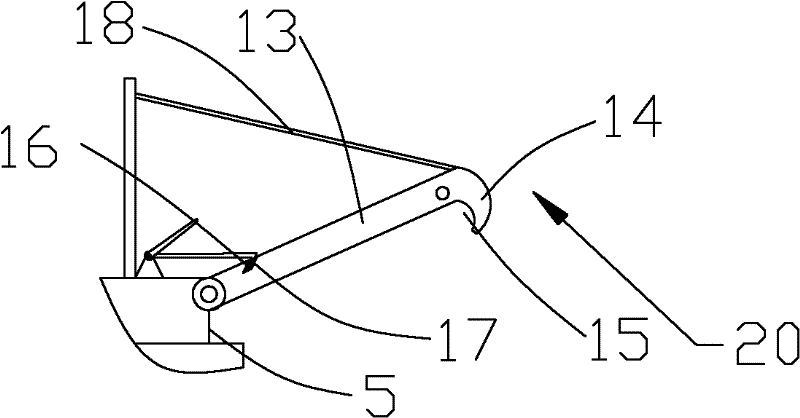

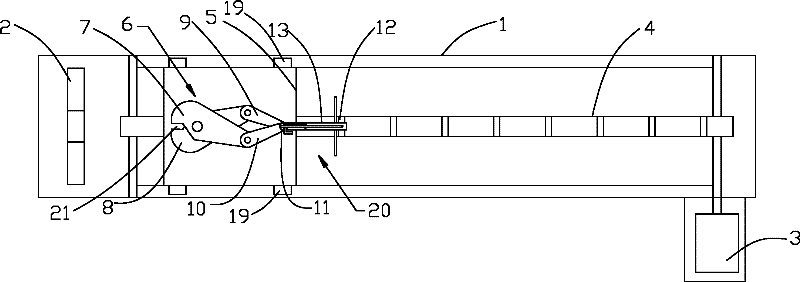

[0014] exist figure 1 and 2 Among them, a drawing machine includes a machine base 1, a mold mounting seat 2 arranged on the machine base 1 for installing a mould, a driving sprocket and a driven sprocket arranged on the machine base 1, and a transmission connection driving sprocket and the drive chain 4 of the driven sprocket, the clamp seat 5 arranged on the machine base 1 to move along the moving direction of the drive chain 4, and the clamp seat 5 arranged on the clamp seat 5 for clamping the drawn piece passing through the mold. The clamp 6 at one end of the object, the connection mechanism 20 used to connect the clamp seat 5 to the transmission chain 4, the driving sprocket is driven to rotate by the motor 3, and is driven by the driven sprocket with the chain 4, and the connection mechanism 20 The chain 4 moves together with the clamp seat 5, and the clamp 6 includes a first clamp block 7 and a second clamp block 8 which are arranged to cross and rotate, and an end por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com