Method for fixing light calcium carbonate as CO2 byproduct by using humate and desulfurization gypsum

A light calcium carbonate, desulfurized gypsum technology, applied in the directions of calcium carbonate/strontium/barium, chemical instruments and methods, separation methods, etc., can solve the problems of limited industrial application, high cost of reaction raw materials, complicated operation process, etc. Low, simple equipment, high carbon sequestration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

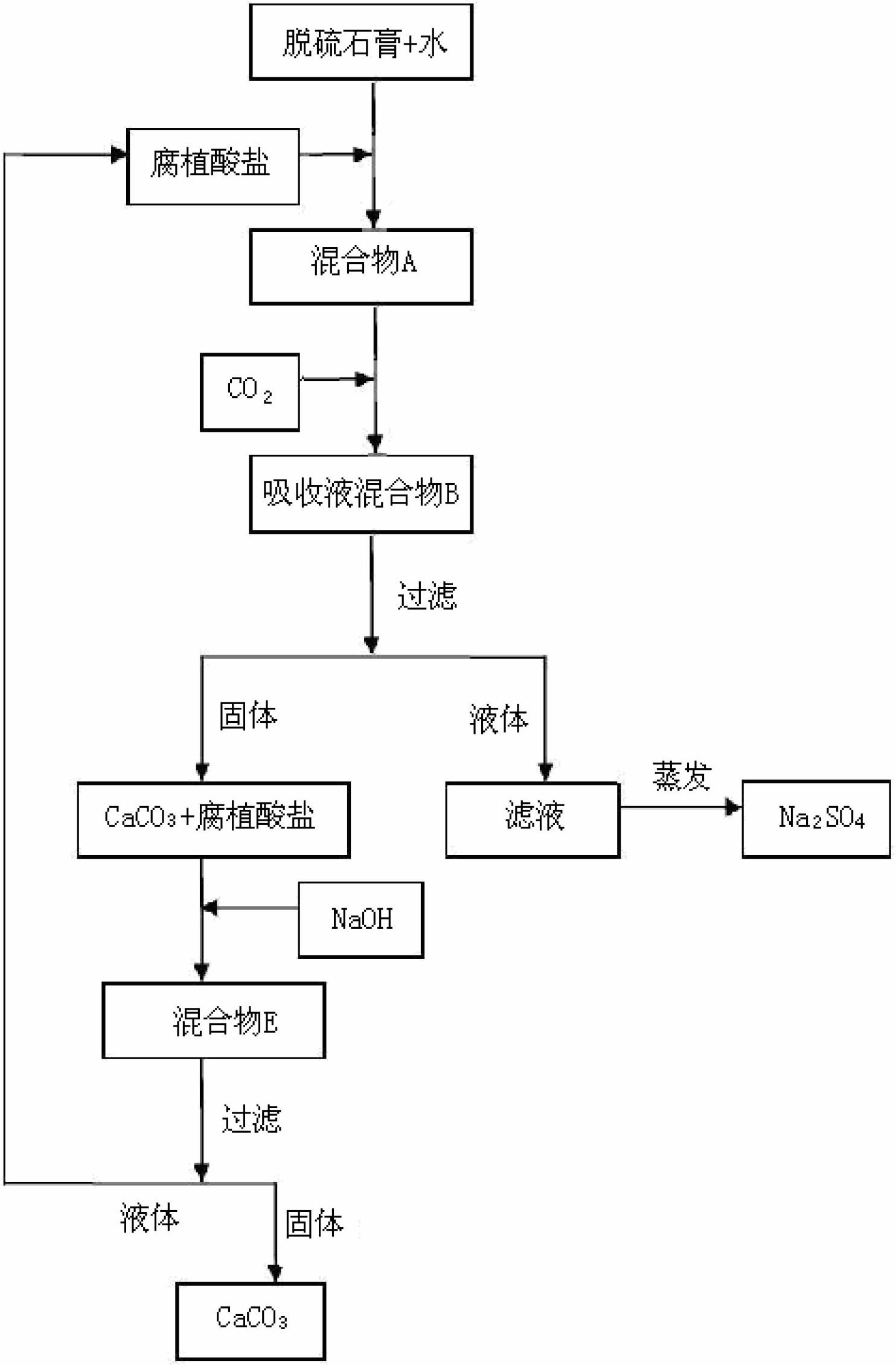

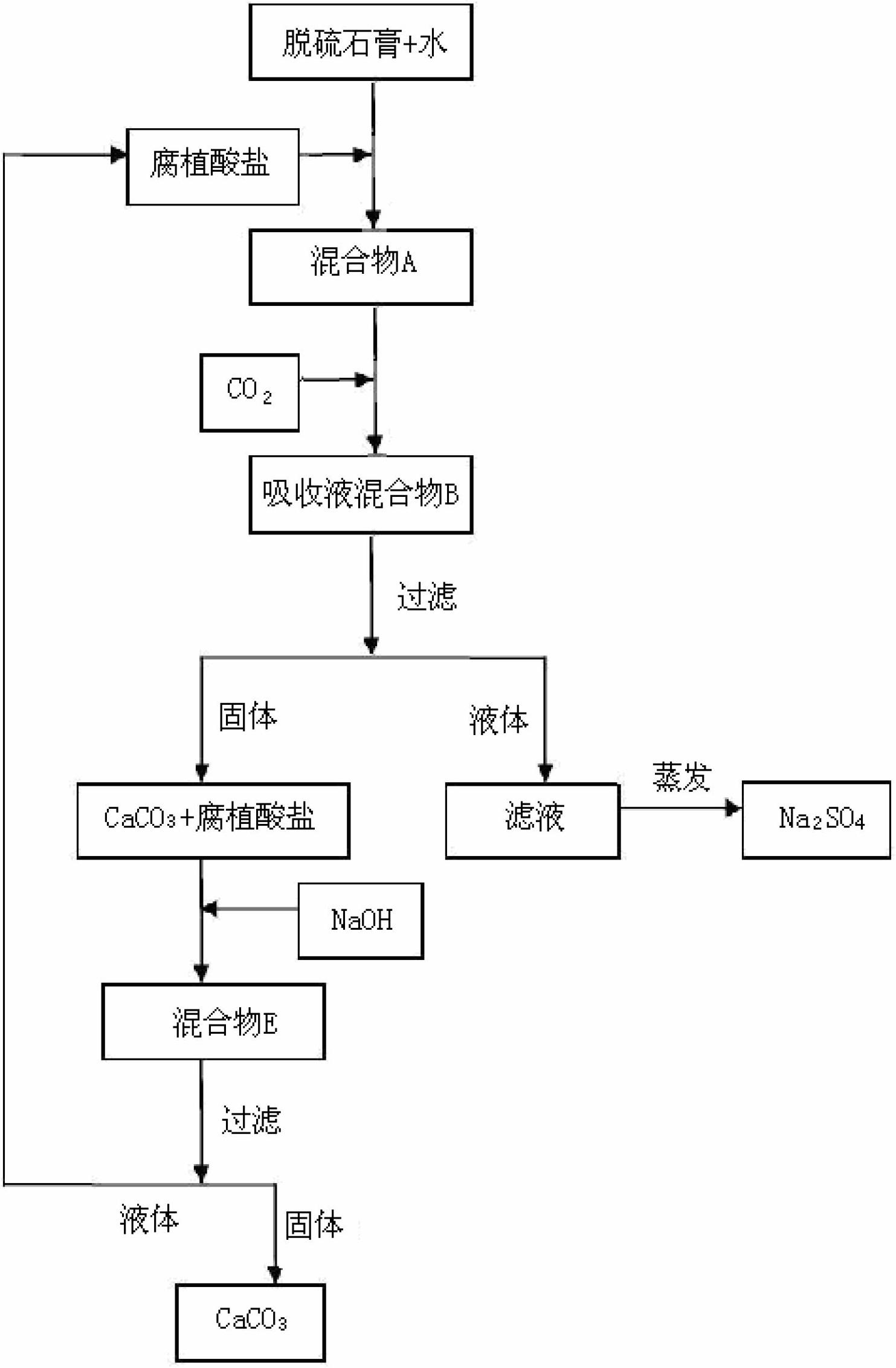

[0020] Such as figure 1 , prepare 0.2L of mixed liquid A of desulfurized gypsum and sodium humate, wherein the mass percentage of desulfurized gypsum is 4%, and the mass percentage of sodium humate is 1%; 15% CO 2 , reacted for 2 hours, can absorb about 2.2g CO 2 , to generate calcium carbonate and humic acid precipitated absorption liquid mixture B; after the absorption liquid mixture B is filtered and precipitated, calcium carbonate and sodium humate precipitated mixture and filtrate are obtained, and the filtrate is heated and evaporated to obtain sodium sulfate by-product. Add NaOH solution to calcium carbonate and humic acid precipitation mixture to obtain mixed solution E, adjust the pH of mixed solution E to 9, humic acid becomes soluble sodium humate, calcium carbonate is still precipitated; the mixture E can be obtained after filtering and drying Light calcium carbonate by-product; the filtrate (sodium humate solution) is added to the absorption liquid formed by des...

Embodiment 2

[0022] Such as figure 1 , prepare 0.2L of mixed liquid A of desulfurized gypsum and sodium humate, wherein the mass percentage of desulfurized gypsum is 9%, and the mass percentage of sodium humate is 2%; 30% CO 2 , reacted for 2 hours, can absorb about 5.3g CO 2 , to generate calcium carbonate and humic acid precipitated absorption liquid mixture B; after the absorption liquid mixture B is filtered and precipitated, calcium carbonate and sodium humate precipitated mixture and filtrate are obtained, and the filtrate is heated and evaporated to obtain sodium sulfate by-product. Add NaOH solution to calcium carbonate and humic acid precipitation mixture to obtain mixed solution E, adjust the pH of mixed solution E to 10, humic acid becomes soluble sodium humate, calcium carbonate is still precipitated; the mixture E can be obtained after filtering and drying Light calcium carbonate by-product; the filtrate (sodium humate solution) is added to the absorption liquid formed by de...

Embodiment 3

[0024] Such as figure 1 , prepare 0.2L of mixed liquid A of desulfurized gypsum and potassium humate, wherein the mass percentage of desulfurized gypsum is 20%, and the mass percentage of potassium humate is 8%; 100% CO 2 , reacted for 2 hours, can absorb about 14.9g CO 2 , to generate calcium carbonate and humic acid precipitated absorption liquid mixture B; after the absorption liquid mixture B is filtered and precipitated, calcium carbonate and sodium humate precipitated mixture and filtrate are obtained, and the filtrate is heated and evaporated to obtain sodium sulfate by-product. Add NaOH solution to calcium carbonate and humic acid precipitation mixture to obtain mixed solution E, adjust the pH of mixed solution E to 10, humic acid becomes soluble potassium humate, calcium carbonate is still precipitated; the mixture E can be obtained after filtering and drying Light calcium carbonate by-product; the filtrate (potassium humate solution) is added to the absorption liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com