Processing method of red dates

A processing method and technology for jujube, applied in the application, food preparation, food science and other directions, can solve the problems of insufficient conversion of jujube polysaccharide and insignificant contribution to the softening effect of jujube fruit, so as to improve taste and flavor, ensure natural flavor, Avoid sugar crusting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

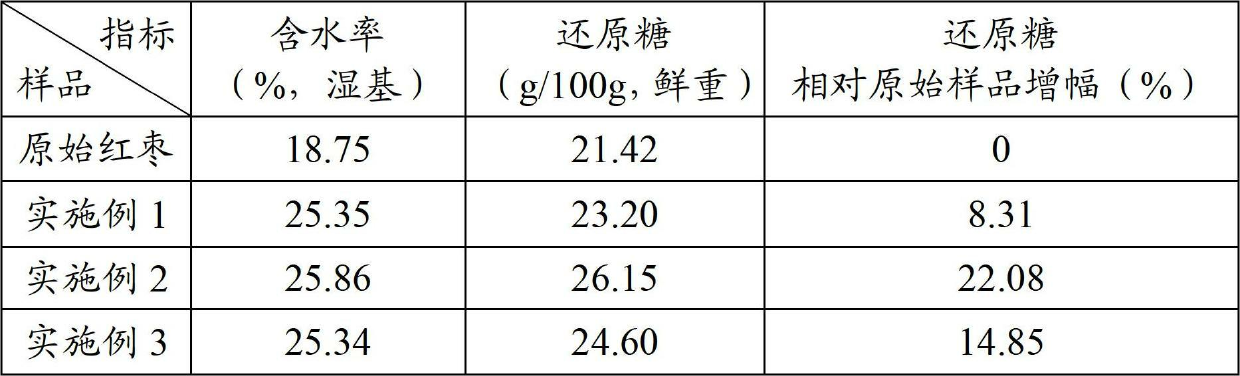

Embodiment 1

[0053] A processing method for jujubes, the steps are as follows: ① select jujubes that are hang-dried on natural trees with a moisture content of 18-20% on a wet basis or basically hang-dried and then dried in the sun. ②Remove the foreign matter in the jujube, and then pick out the unqualified jujubes such as broken jujube, moldy jujube, pulp-head jujube, insect-eaten jujube, etc., and then use cleaning equipment to clean and wet the jujube. ③ Place the cleaned jujubes under certain temperature and humidity conditions, and perform polysaccharide conversion and softening treatment on the jujubes, wherein the treatment temperature is 35-65°C, the relative humidity is 40-50%, and the treatment time is 5 hours;

[0054] The softening process includes the following stages:

[0055] The first stage: treatment temperature 35~50℃, relative humidity 45~50%, treatment time 1.5h;

[0056] The second stage: treatment temperature 50~55℃, relative humidity 45~50%, treatment time 1.0h;

...

Embodiment 2

[0062] A processing method for jujubes, the steps are as follows: ① select jujubes that are hang-dried on natural trees with a moisture content of 18-20% on a wet basis or basically hang-dried and then dried in the sun. ②Remove the foreign matter in the jujube, and then pick out the unqualified jujubes such as broken jujube, moldy jujube, pulp-head jujube, insect-eaten jujube, etc., and then use cleaning equipment to clean and wet the jujube. ③ Place the cleaned jujubes under certain temperature and humidity conditions, and perform polysaccharide conversion and softening treatment on the jujubes, wherein the treatment temperature is 35-60°C, the relative humidity is 35-55%, and the treatment time is 4 hours;

[0063] The softening process includes the following stages:

[0064] The first stage: treatment temperature 35~50℃, relative humidity 50~55%, treatment time 2.0h;

[0065] The second stage: treatment temperature 50~55℃, relative humidity 45~50%, treatment time 1.0h;

...

Embodiment 3

[0070] A processing method for jujubes, the steps are as follows: ① select jujubes that are hang-dried on natural trees with a moisture content of 18-20% on a wet basis or basically hang-dried and then dried in the sun. ②Remove the foreign matter in the jujube, and then pick out the unqualified jujubes such as broken jujube, moldy jujube, pulp-head jujube, insect-eaten jujube, etc., and then use cleaning equipment to clean and wet the jujube. ③ Place the cleaned jujubes under certain temperature and humidity conditions, and perform polysaccharide conversion and softening treatment on the jujubes, wherein the treatment temperature is 30-60°C, the relative humidity is 35-55%, and the treatment time is 5 hours;

[0071] The softening process includes the following stages:

[0072] The first stage: treatment temperature 30~50℃, relative humidity 45~55%, treatment time 2.5h;

[0073] The second stage: treatment temperature 50~55℃, relative humidity 40~45%, treatment time 0.5h;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com