Method for making sour natto by fermenting budded soybean through fibrinolytic bacteria and probiotics

A probiotic and fibrinolytic technology, applied in food preparation, application, food science and other directions, can solve problems such as bad taste, inappropriateness, and dislike of eating, so as to increase market value, prevent the formation of blood clots, and reduce gastrointestinal irritation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: 1. select 250g of soybeans with uniform particle size, round and plump, thin skin and yellow color, soak in 1200mL water for 8h after cleaning, remove the soybeans that are fully soaked and absorb water, drain off the water, at humidity 65% humidity, temperature Germinated for 13h in a 30°C environment in the dark for 13 hours. At this time, the germination is over, and the germ will emerge but the seed coat has not been broken; ② Filter out the germinated soybeans and rinse them under running water for 3 times. Take 500g of germinated soybeans, add 5g of salt, 55g soft white sugar, sterilized at 121°C for 15min, when cooled to 40°C, first add 20mL with a concentration of 10 8 cfu / mL Lactobacillus acidophilus was fermented at 42°C for 24h, and then added to 20mL at a concentration of 10 8 Bacillus natto with cfu / mL was fermented at 37°C for 24h. Take out and put it at 4°C and cook for 72 hours to obtain sour natto.

specific Embodiment approach 2

[0012] Specific embodiment 2: 1. the same as the first step of specific embodiment 1; 2. filter out the sprouted soybeans, and rinse 3 times under running water, get 500g of sprouted soybeans, add 5g salt, 45g soft white sugar, sterilize at 121 ° C for 15min , when cooled to 40°C, add 20mL at the same time with a concentration of 10 8 cfu / mL of Lactobacillus acidophilus and 20mL at a concentration of 10 8 Bacillus natto with cfu / mL was fermented at 37°C for 36h. Take out and put it at 4°C and cook for 24 hours to obtain sour natto.

specific Embodiment approach 3

[0013] Specific embodiment 3: 1. the same as the first step of specific embodiment 1; 2. filter out the sprouted soybeans, and rinse 3 times under running water, get 500g of sprouted soybeans, add 5g salt, 55g soft white sugar, sterilize at 121 ° C for 15min , when it is cooled to 40 °C, the concentration is 10 8 10 mL each of Bacillus natto, Bacillus subtilis, Lactobacillus acidophilus and Lactobacillus plantarum with cfu / mL were fermented at 40°C for 12h. Take out and put it at 4°C and cook for 48 hours to obtain sour natto.

[0014] The following is a part of the experimental data (data obtained by operating according to the specific embodiment 1):

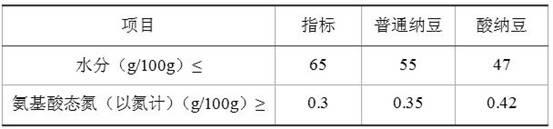

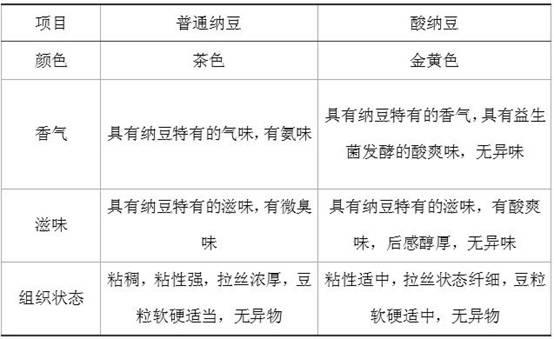

[0015] 1. Physical and chemical indicators

[0016] According to the provisions of the People's Republic of China domestic trade industry standard SB / T10528-2009 natto, the physical and chemical indicators of acid natto and traditional natto were tested. Determination of moisture content according to GB / T5009.3 method, amino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com