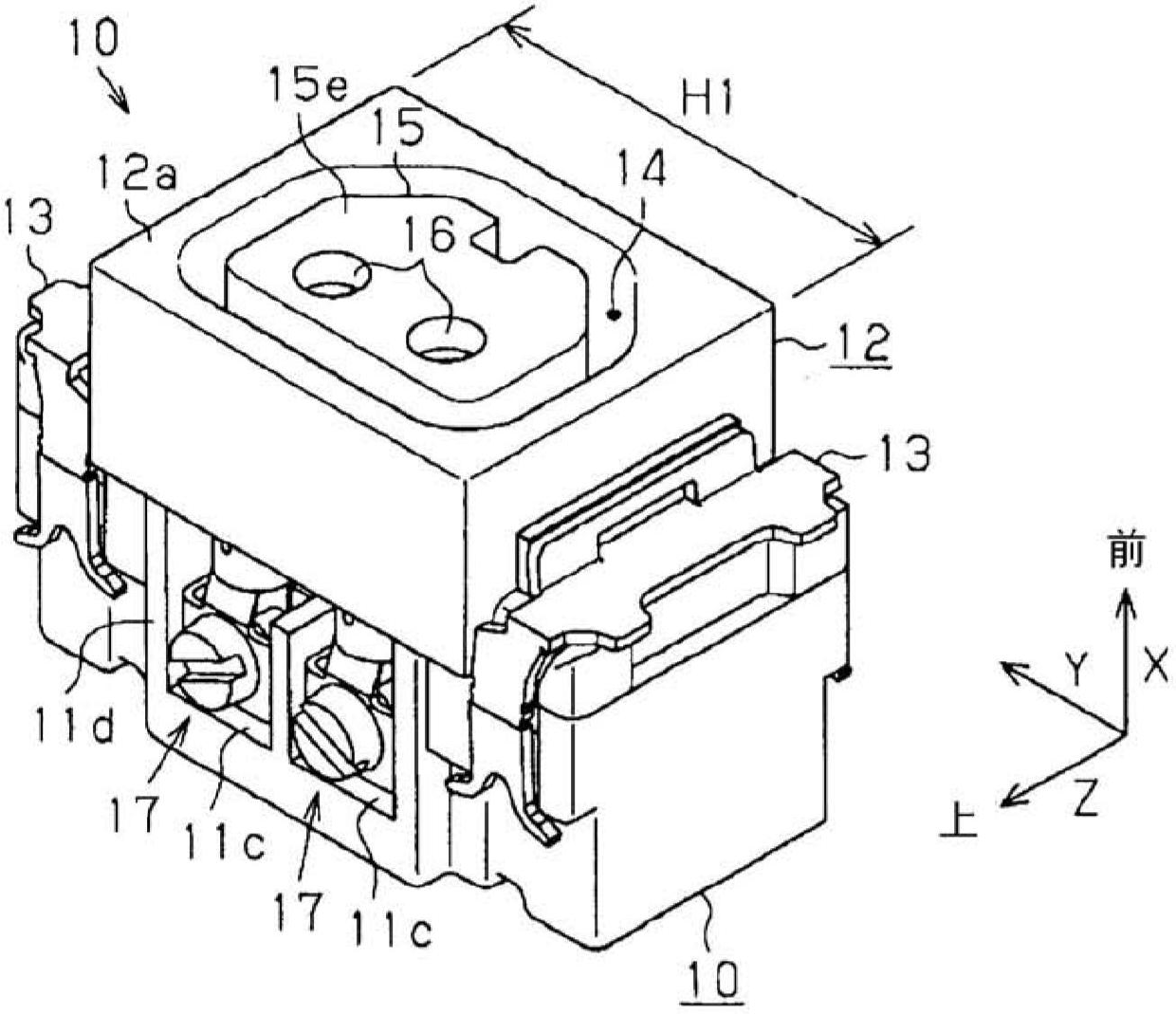

Screw terminal and receptacle including same

A screw and terminal technology, applied in the socket field including the screw terminal, can solve the problems of complex bending process, increased cost, difficulty in manufacturing screw terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

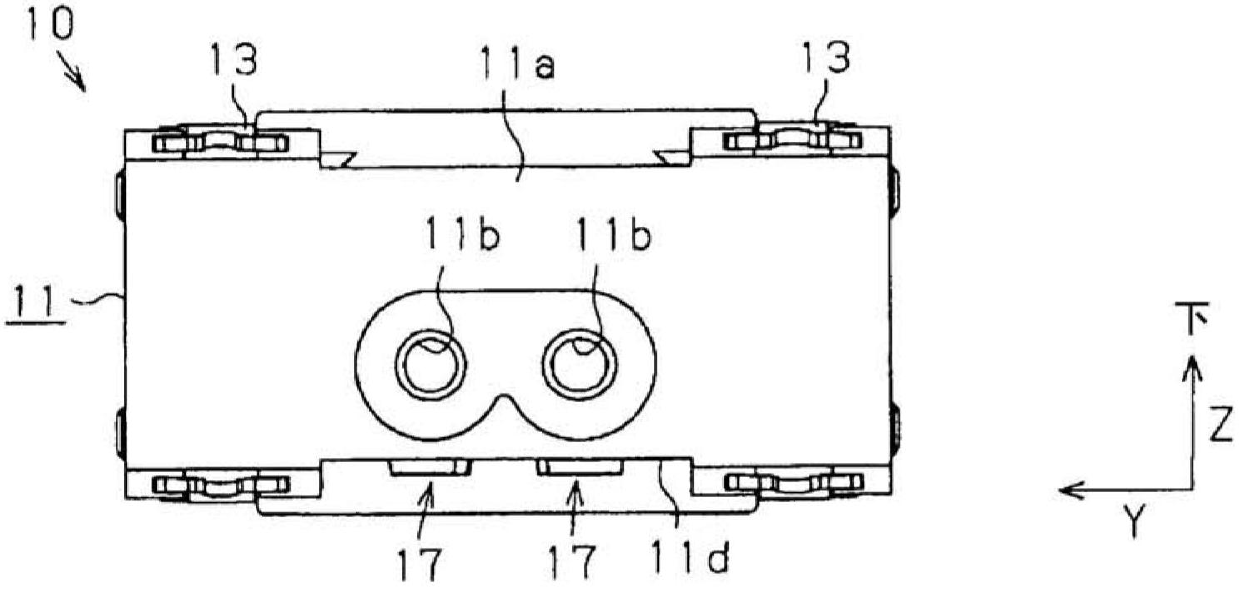

Examples

Embodiment )

[0111] The socket 10 of the present invention is not limited to the above embodiments, and may be modified as described below. In addition, the following modifications are applicable to the foregoing embodiments, and combinations of various modifications may also be possible.

[0112] In the above-described embodiments, a DC outlet is used as the outlet 10 . However, an AC outlet supplied with AC power may be used as the outlet 10 .

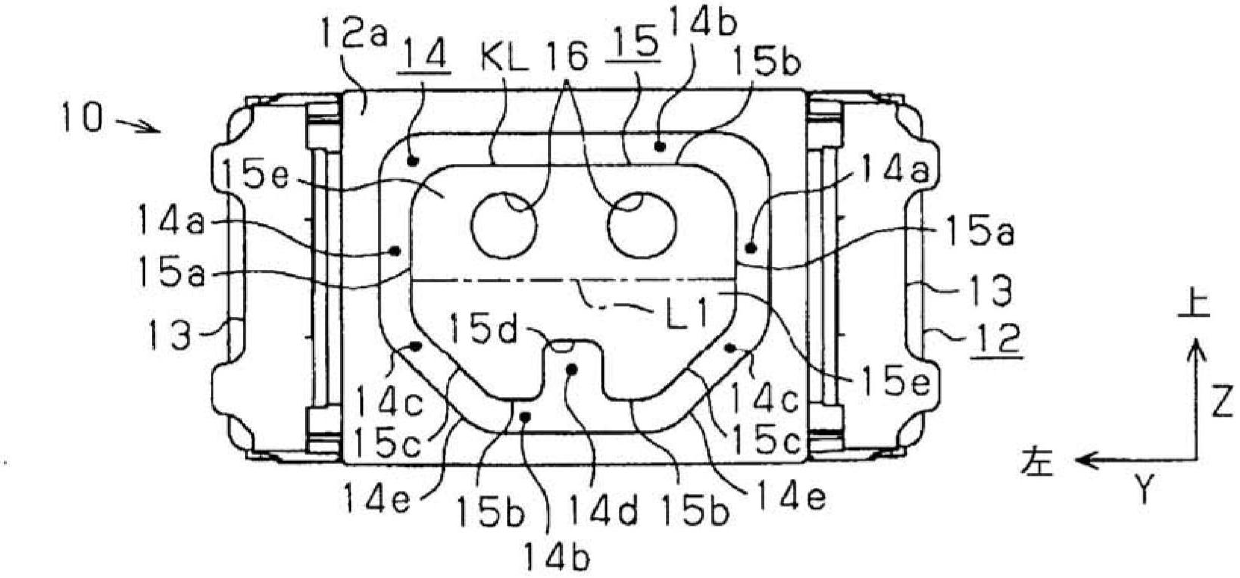

[0113] Although the pin insertion hole 16 is positioned above the center line L1 in the above-described embodiment, the pin insertion hole 16 may be positioned at the same level as the center line L1 or positioned below the center line L1.

[0114] In the above-described embodiment, two inclined grooves 14 c and one extended groove 14 d are provided at the peripheral wall insertion groove 14 . However, the shape of the peripheral wall insertion groove 14 is not limited to the above. For example, if Figure 10 As shown in , the peripheral wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com