Modeling method for catalytic cracking main fractionator with varying-population-size DNA genetic algorithm

A genetic algorithm and catalytic cracking technology, applied in the field of catalytic cracking main fractionator modeling, can solve problems such as slow convergence speed, local minimum, over-learning, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

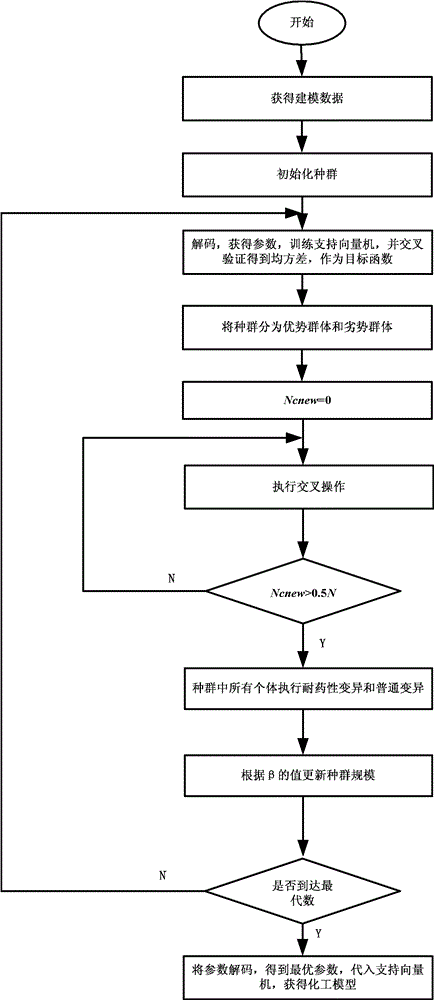

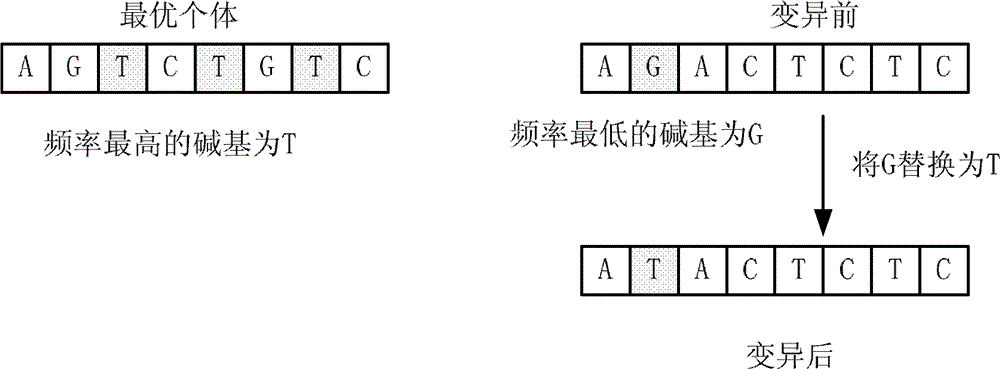

Method used

Image

Examples

Embodiment

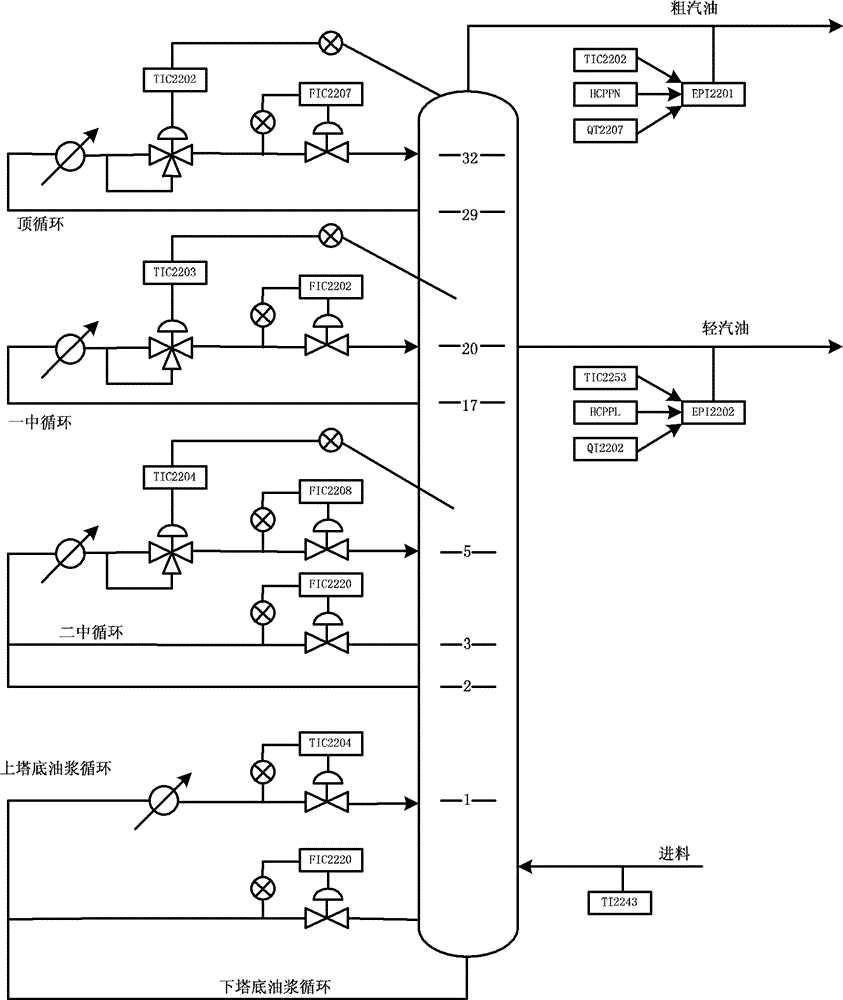

[0073] As an important secondary processing technology in the oil refining industry, the catalytic cracking process can convert heavy raw materials into light products, which has a significant impact on the economic benefits of oil refineries. Among them, the catalytic cracking main fractionator is an important unit to realize product separation. Accurate modeling and operation optimization of the catalytic cracking main fractionator is one of the effective measures to reduce the energy consumption of the catalytic cracking unit and improve economic benefits.

[0074] The flow chart of the catalytic cracking main fractionation tower system is as follows: Figure 4 As shown, according to the analysis of the process flow, the top cycle MV1, the flow rate of the first medium MV2 and the flow rate of the second medium MV3 are the operating variables; the tower top temperature CV1, the dry point of naphtha CV2 and the pour point of light oil CV3 are the controlled variables. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com