Method for fast detecting plugging degree of oxide skins on inner wall of austenitic stainless steel tubes

A technology of austenitic stainless steel and detection method, which is applied in measurement device, geophysical measurement, radio wave measurement system, etc., can solve the problems of cumbersome implementation, inability to complete, poor filming effect, etc. Simple data processing and stable measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

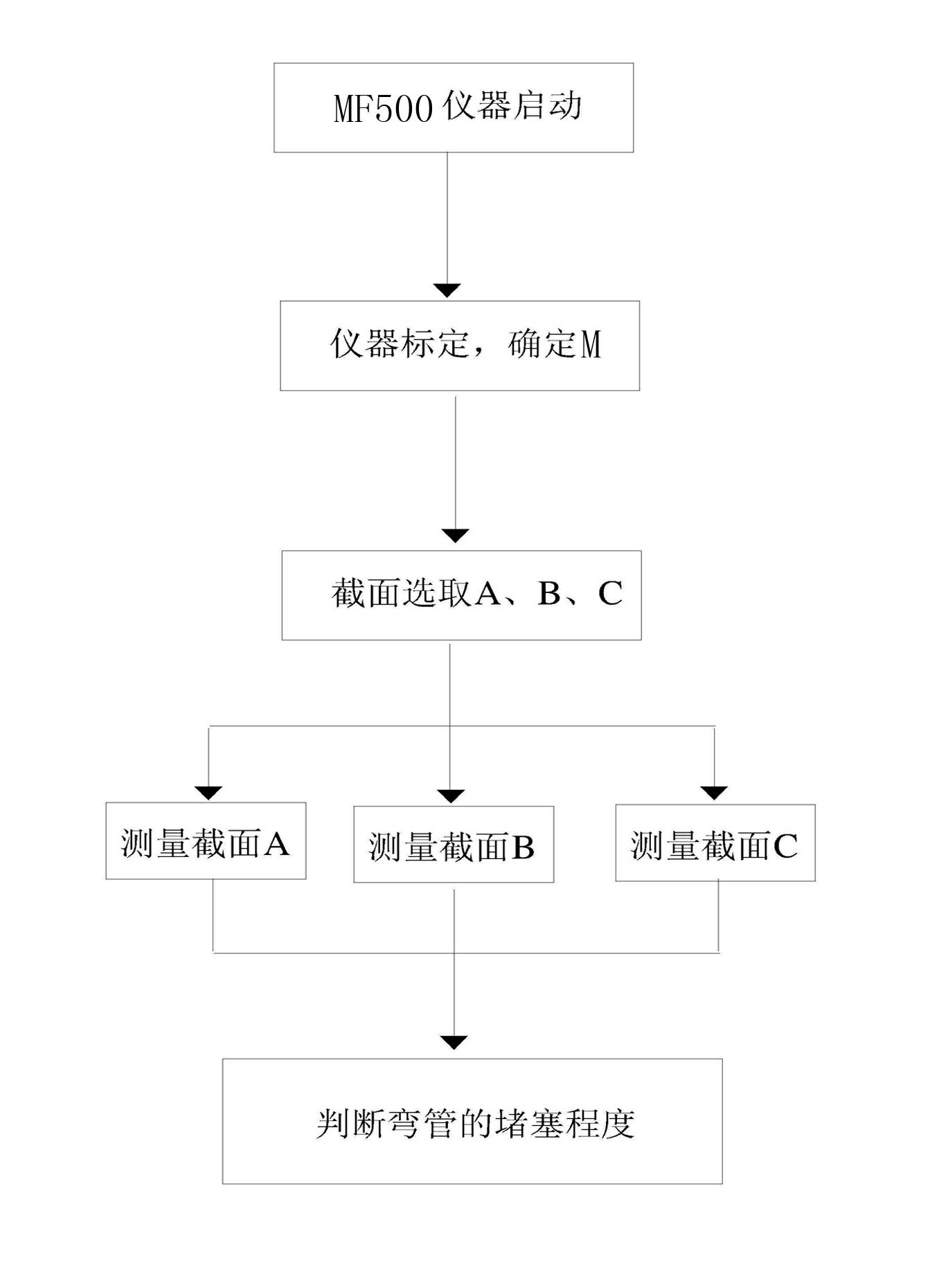

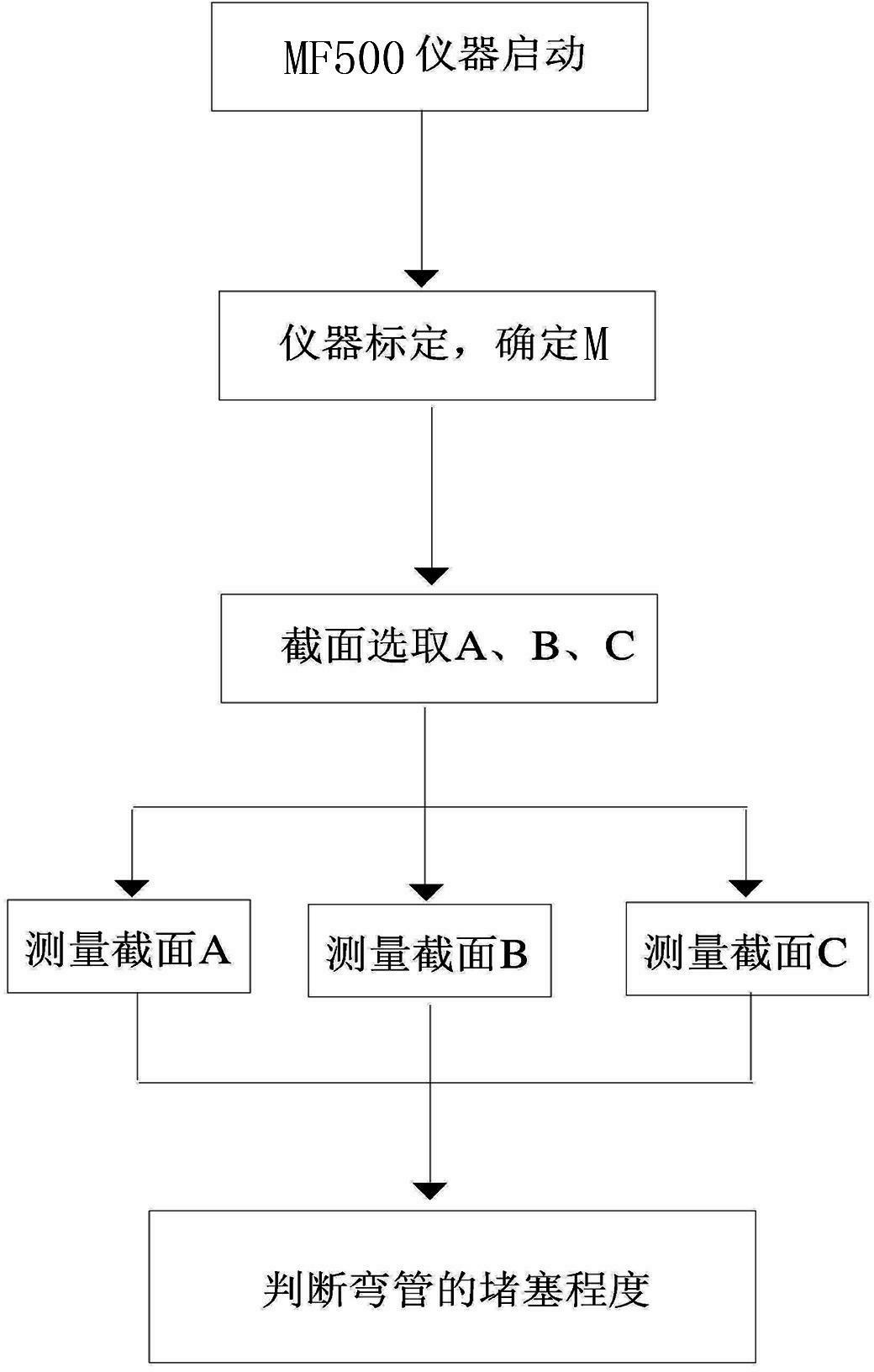

Method used

Image

Examples

example 1

[0028] One elbow of the high-temperature reheater was tested, and the A1 value was 28 A / m, which was less than 10% of M, so it was judged that there was no oxide scale accumulation in the elbow.

example 2

[0030] Test one elbow of the high-temperature reheater, the A1 value is 98A / m, greater than 40 A / m, and less than 120 A / m, judging that there may be scale accumulation in this section of the elbow, continue to measure A2 to 100 A / m, A3 A / m is 110 A / m, A4 is 90 A / m, A2, A3, A4 are all less than 120 A / m, but (A2+A3+A4) / 3 is 120 A / m greater than 80 A / m, judge this section of the bend The tube has scale buildup.

example 3

[0032] One elbow of the high-temperature reheater was tested, and the A1 value was 158A / m. It was judged that there was scale accumulation in this elbow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com