Light guide plate and backlight module with the light guide plate

A technology of backlight module and light guide plate, applied in the field of backlight module, can solve the problems of light leakage, diffuse reflection of light, etc., and achieve the effect of simple production, low cost, and guaranteed light intensity and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

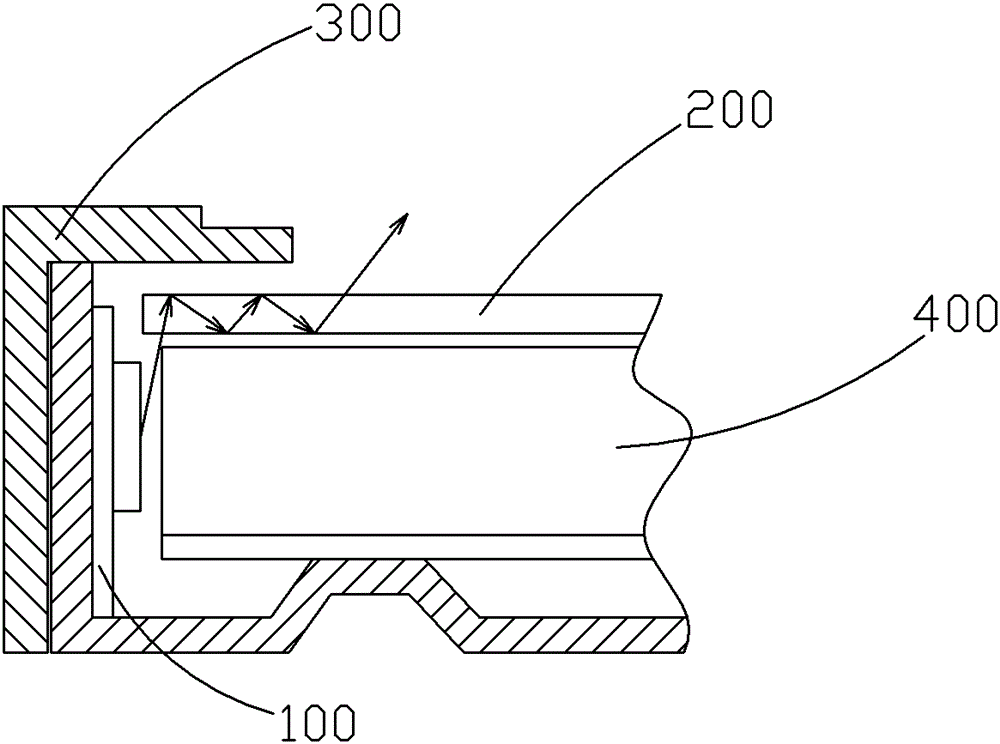

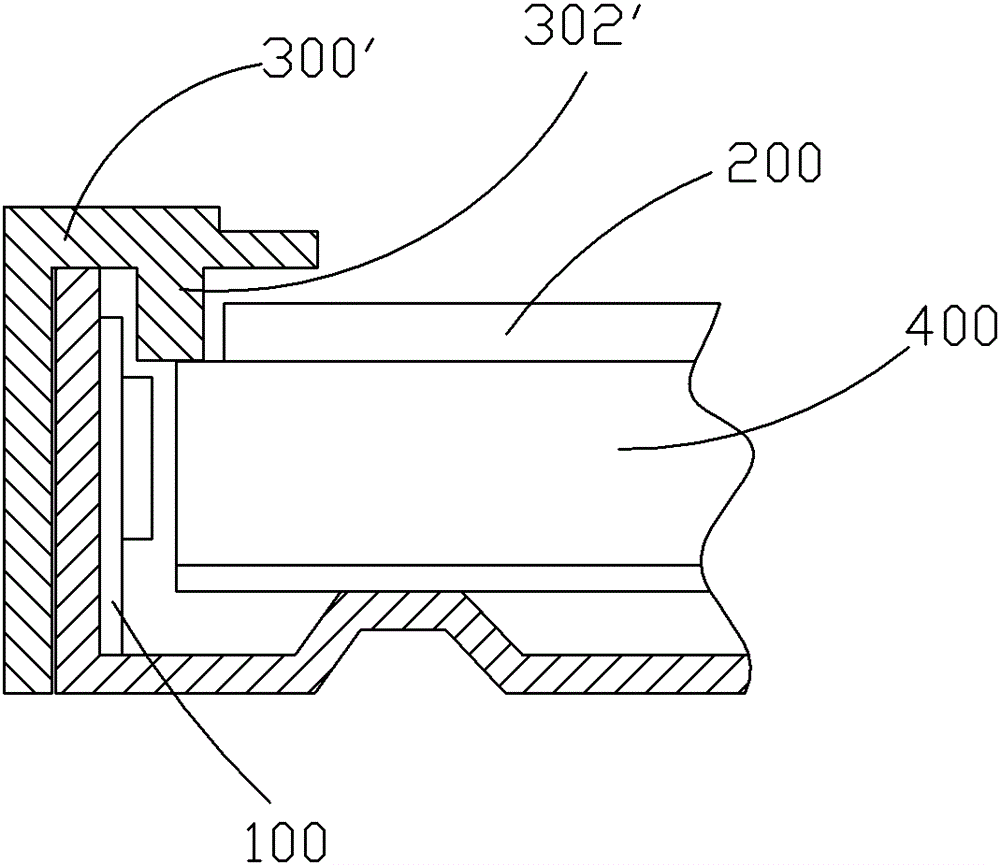

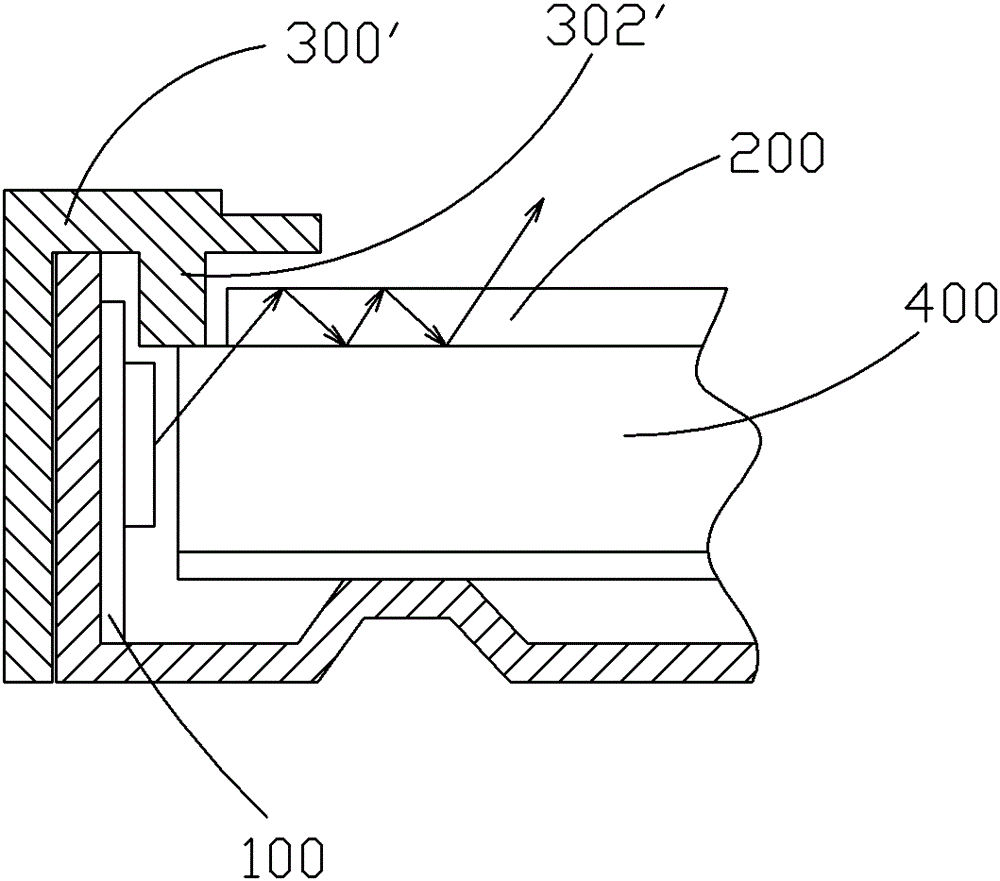

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0033] see Figure 5 , the light guide plate 10 according to an embodiment of the present invention includes: a body 12 and a coating 14 disposed on the body 12, the body 12 includes a bottom surface 122, a top surface 124 corresponding to the bottom surface 122, and a top surface 124 located between the bottom surface 122 and the top surface 124 Between several side surfaces 126, the coating 14 is provided on at least one side of the top surface 124, the refractive index of the coating 14 is greater than or equal to 1, and is smaller than the refractive index of the body 12, and n represents coating layer refractive index, n air represents the refractive index of air, n LGP Represents the refractive index of the main body 12 of the light gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com