Electronic gear detection mechanism based on photoelectric sensors

A photoelectric sensor, electronic gear technology, applied in mechanical equipment, components with teeth, transmission control and other directions, can solve the problems of poor anti-electromagnetic interference performance, poor anti-mechanical jitter performance, high manufacturing process requirements, and achieve error prevention. Enhanced triggering ability, fast response, and easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

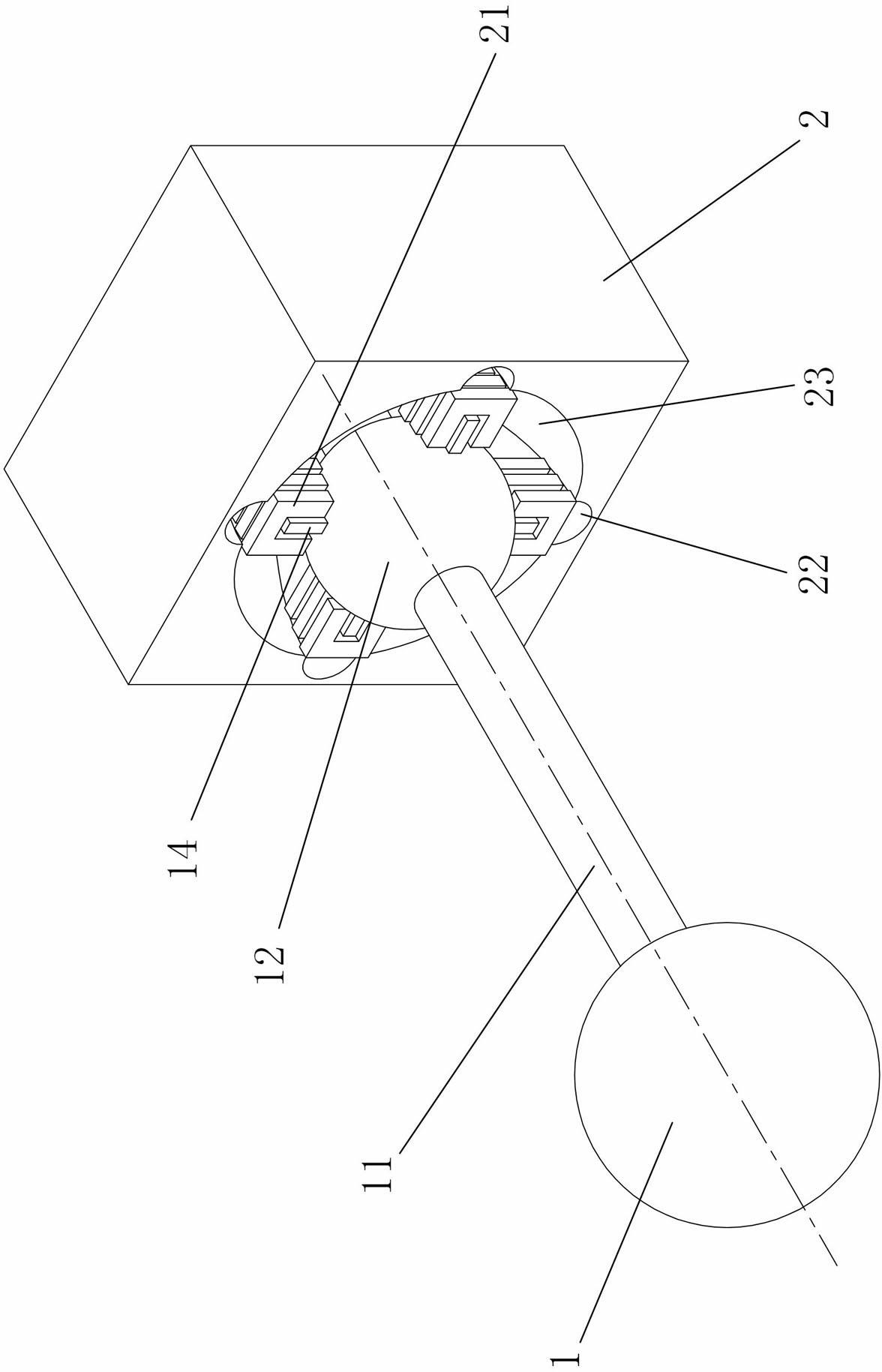

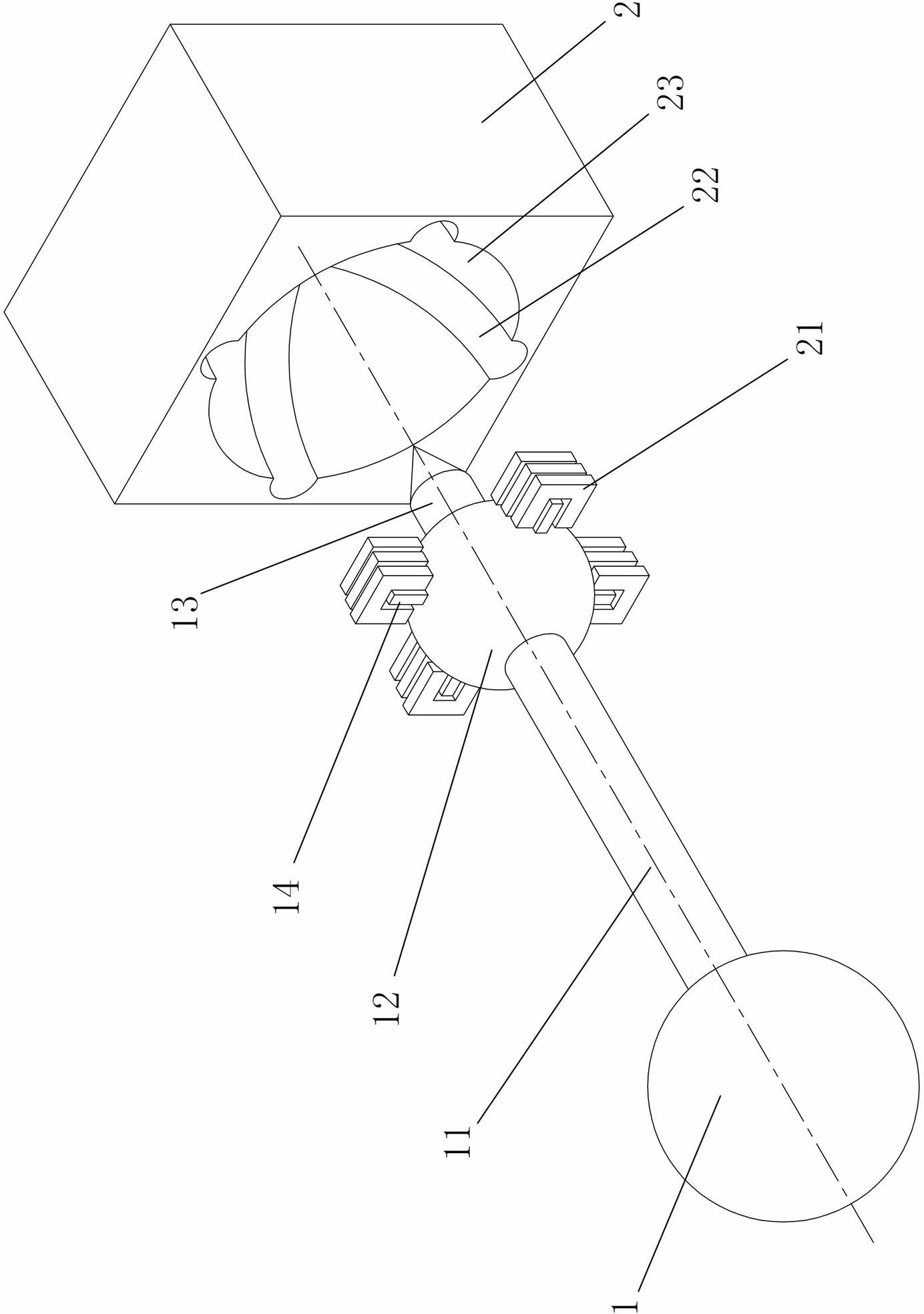

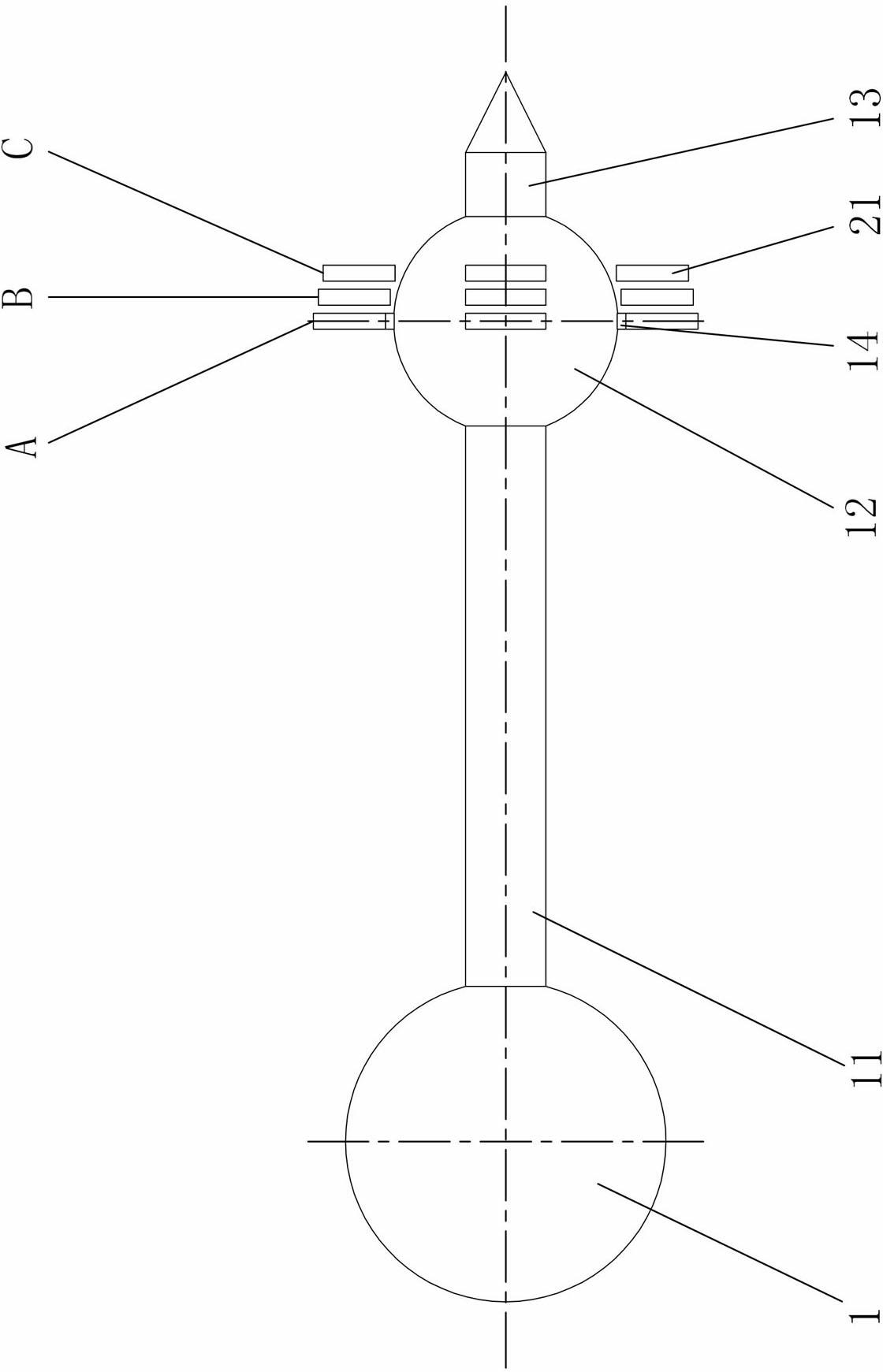

[0020] figure 1 with figure 2 It shows an embodiment of an electronic gear detection mechanism based on a photoelectric sensor of the present invention, including a joystick 1 and a handle base 2, and the joystick 1 is formed by sequentially connecting an operating handle 11, a central ball 12 and a retractable tip 13, The center ball 12 and the retractable tip 13 are installed in the handle base 2, and the center ball 12 is evenly provided with a plurality of light-shielding baffles 14 along the circumference of the joystick 1, and the inside of the handle base 2 corresponds to each light-shielding baffle. 14 are respectively equipped with a group of photoelectric sensor groups connected with the electronic gear control circuit. The photoelectric sensor group is composed of at least two layers of photoelectric sensors 21. Generate movement relative to the photoelectric sensor group, trigger the photoelectric sensor 21 to send an electrical signal to the control circuit, its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com