Method and device for driving internal combustion engine by straight shaft

A technology of internal combustion engine and direct shaft, which is applied in the direction of transmission, machine/engine, mechanical equipment, etc. It can solve the problems of wasting fuel, hindering the output torque of internal combustion engine, etc., and achieve the goal of improving output efficiency, reducing radial force and high output efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

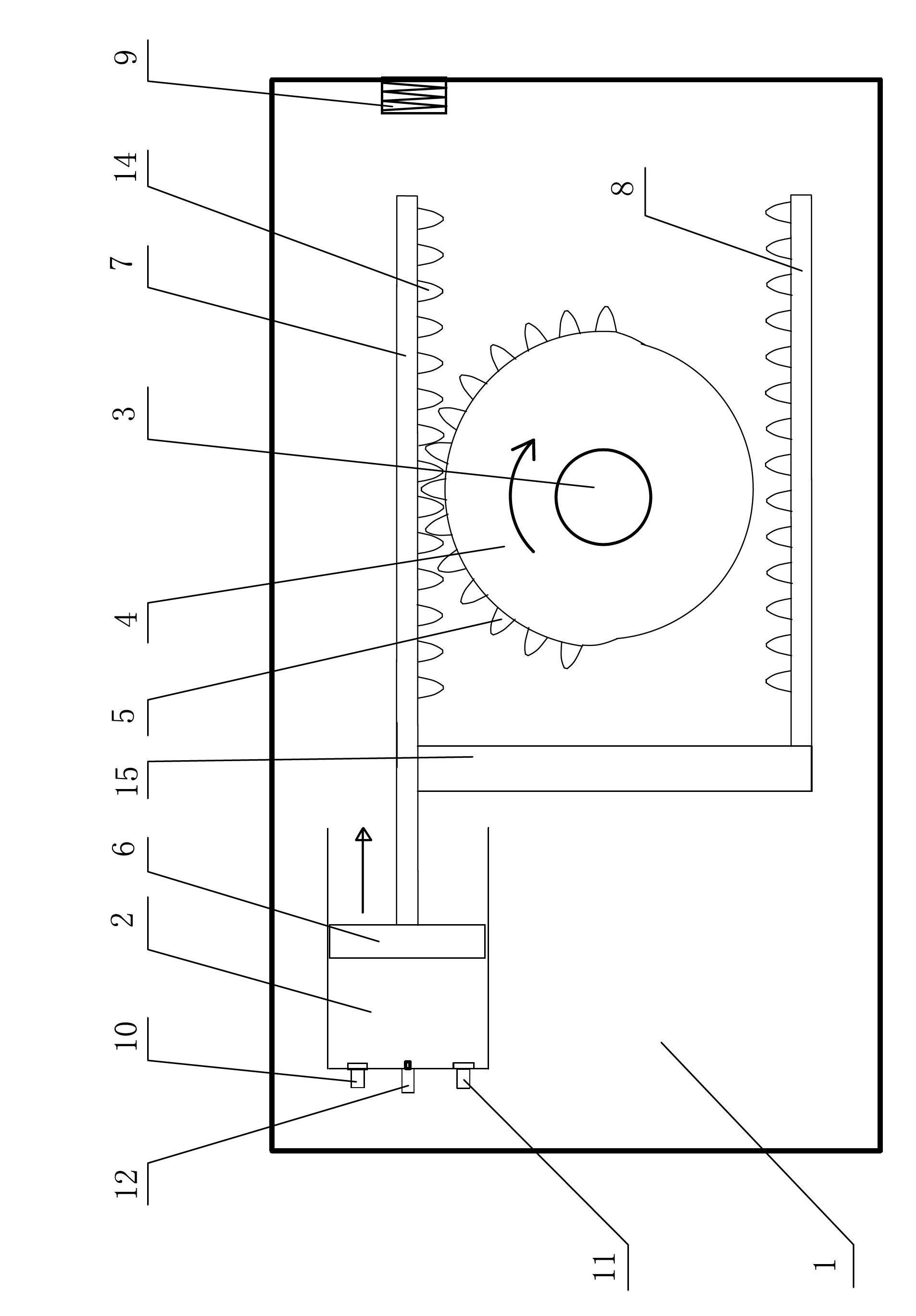

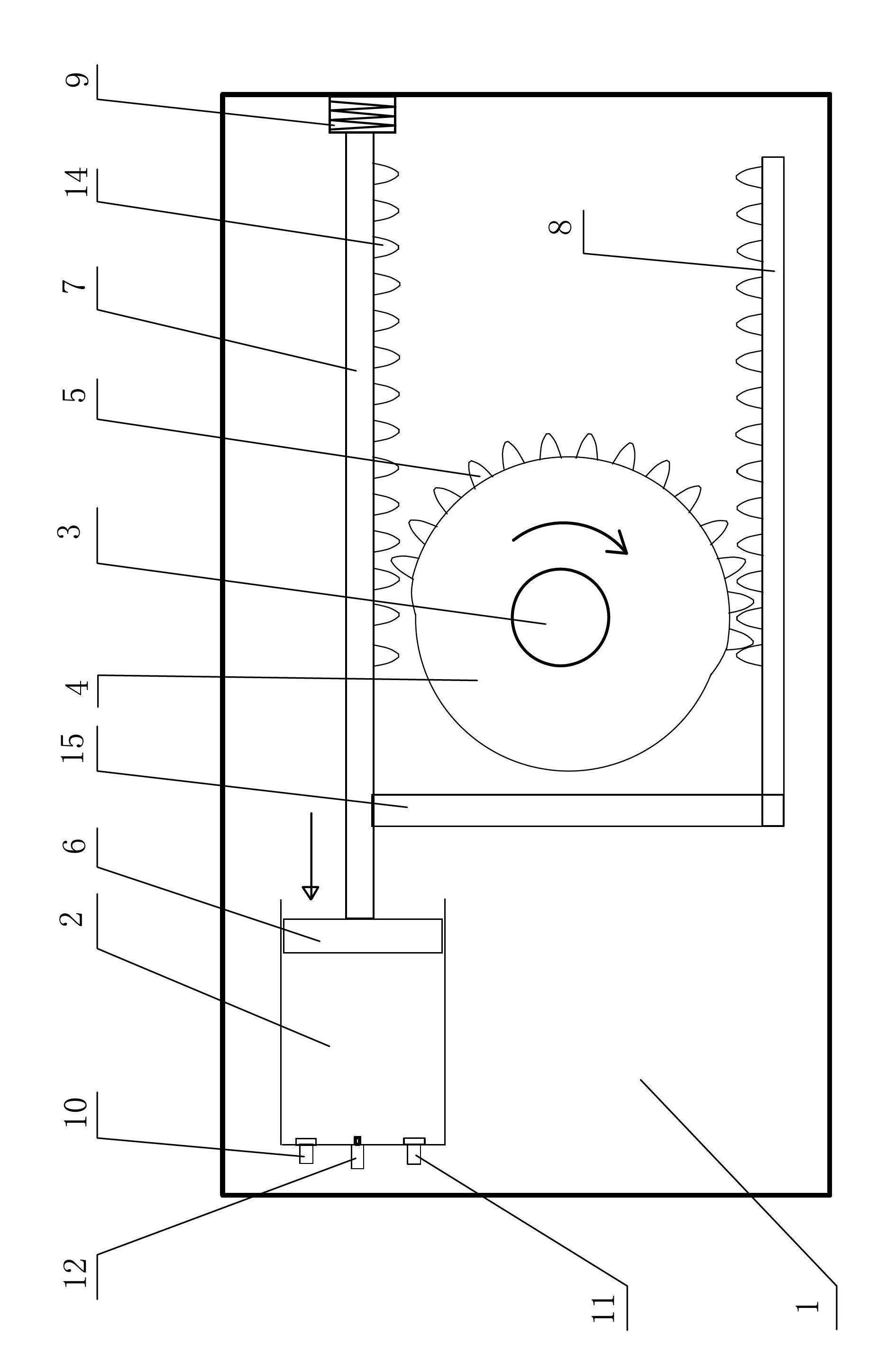

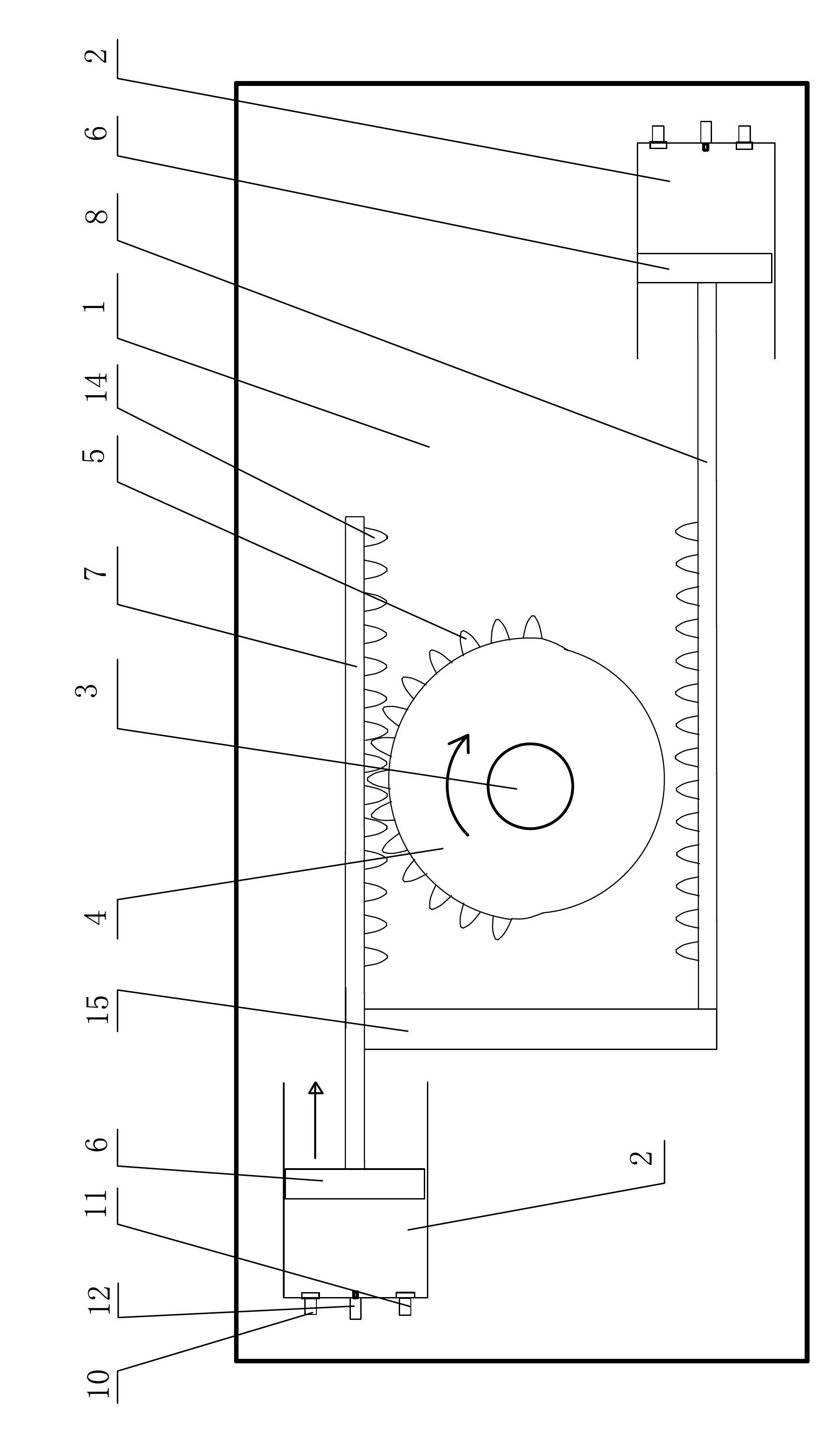

[0028] The device, method and technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] The direct axis drive internal combustion engine device of the present invention is made up of connecting rod and connecting rod driving mechanism, and described connecting rod is made of parallel straight connecting rod 7 and secondary connecting rod 8, and described secondary connecting rod 8 is connected with straight connecting rod by vertical transmission rod 15 7 rod body connection (the transmission rod 15 and the secondary connecting rod 8 form an "L" shape); the connecting rod drive mechanism includes a straight shaft 3, a transmission wheel 4, a half-circular gear 5 meshing with each other, a rack 14 and a flywheel 13, so Said driving wheel 4 and flywheel 13 are coaxially installed on the straight shaft 3, and the driving wheel 4 is placed in the plane where the straight connecting rod 7 and the auxiliary con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com