High-molecular polymer dust suppressant compound and preparation method thereof

A high-molecular polymer and high-molecular compound technology, applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of refractory degradation, environmental secondary pollution, corrosion, etc., and achieve good dust-proof effect and low price , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

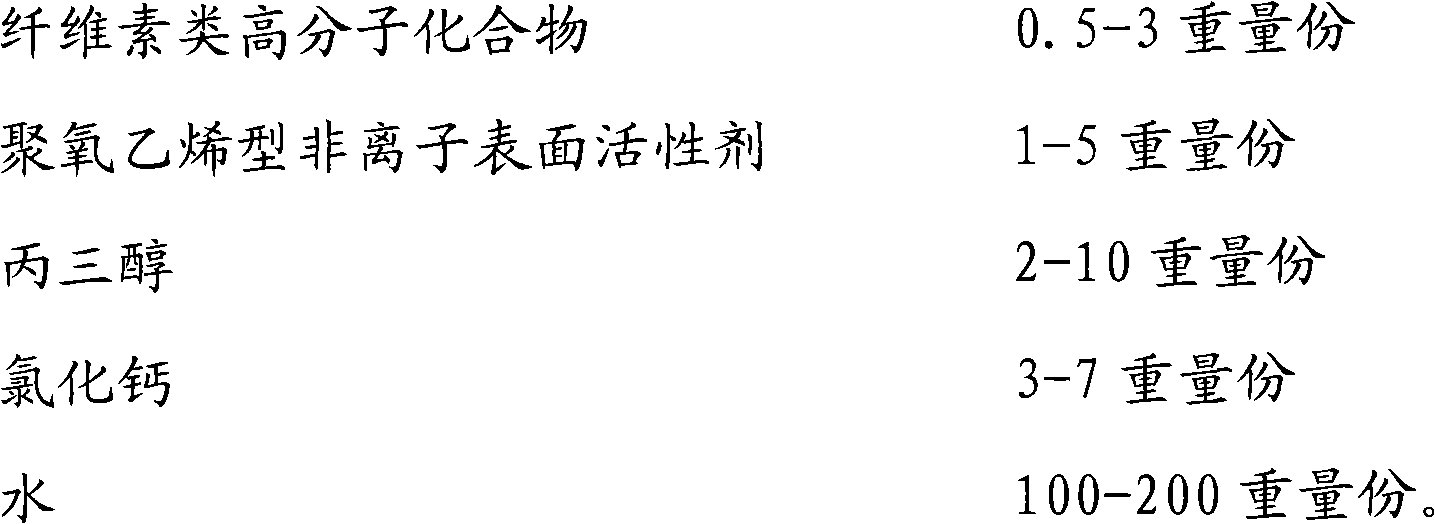

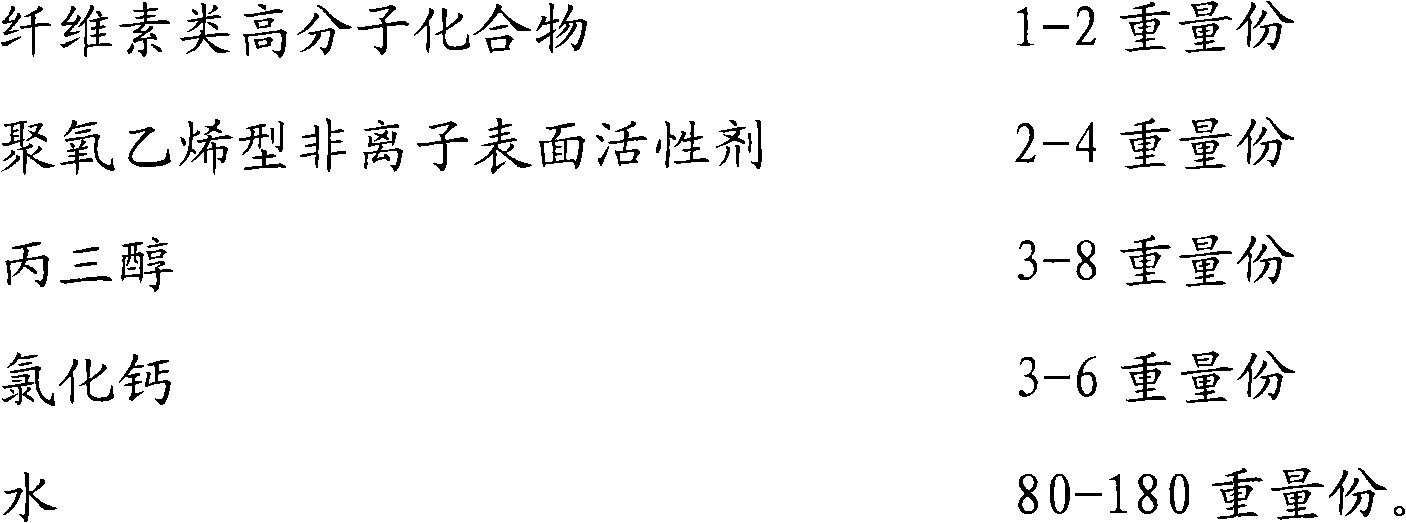

Method used

Image

Examples

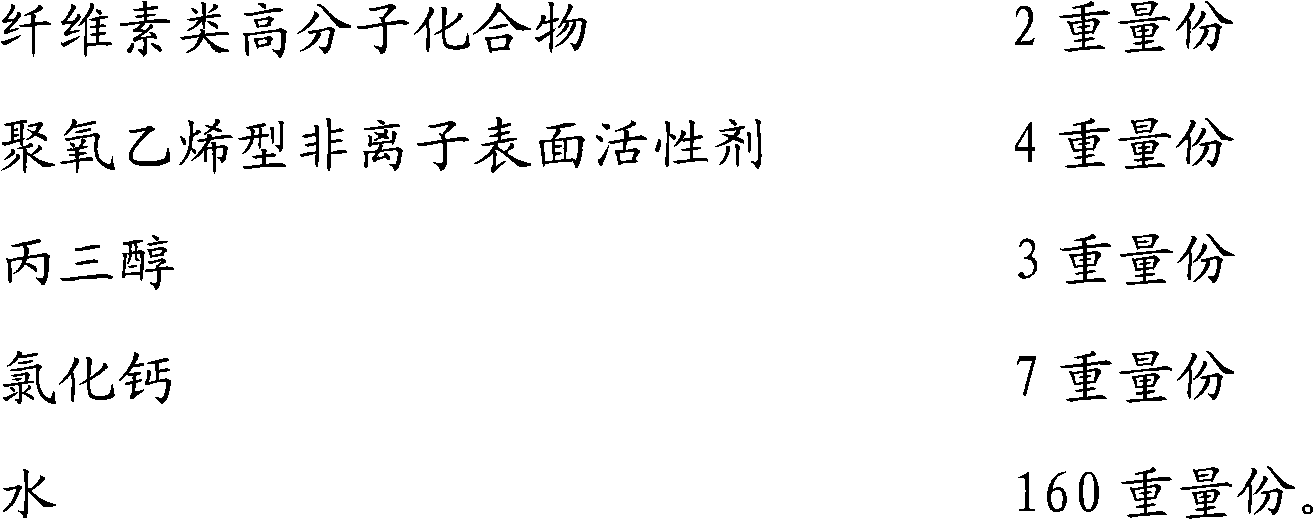

Embodiment 1

[0026] Embodiment 1: High molecular polymer dust suppressant composition of the present invention

[0027] The preparation method is as follows:

[0028] A. Stir and dissolve 2 parts by weight of cellulose polymer compound with 160 parts by weight of water;

[0029] B. Add 4 parts by weight of polyoxyethylene type nonionic surfactant, 3 parts by weight of glycerol and 7 parts by weight of calcium chloride in the solution obtained in step A, and stir slowly until completely dissolved;

[0030] C. Let the completely dissolved solution obtained in step B stand for 5-6 hours to obtain the high molecular polymer dust suppressant.

Embodiment 2

[0031] Embodiment 2: polymer dust suppressant composition of the present invention

[0032] The preparation method is as follows:

[0033] A. Stir and dissolve 0.5 parts by weight of cellulose polymer compound with 100 parts by weight of water;

[0034] B. Add 1.5 parts by weight of polyoxyethylene type nonionic surfactant, 5 parts by weight of glycerol and 3 parts by weight of calcium chloride in the solution obtained in step A, and stir slowly until completely dissolved;

[0035] C. Let the completely dissolved solution obtained in step B stand for 5-6 hours to obtain the high molecular polymer dust suppressant.

Embodiment 3

[0036] Embodiment 3: polymer dust suppressant composition of the present invention

[0037] The preparation method is as follows:

[0038] A, stirring and dissolving 3 parts by weight of cellulose polymer compound with 200 parts by weight of water;

[0039] B. Add 4 parts by weight of polyoxyethylene type nonionic surfactant, 9 parts by weight of glycerol and 4 parts by weight of calcium chloride in the solution obtained in step A, and stir slowly until completely dissolved;

[0040] C. Let the completely dissolved solution obtained in step B stand for 5-6 hours to obtain the high molecular polymer dust suppressant.

[0041] Table: Implementation effect of dust suppressant of the present invention on different dust

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com