Packaging machine capable of automatically adding corner protectors

A technology of balers and corner protectors, which is applied to the parts of bundling machinery, etc., can solve the problems of waste of manpower and material resources, low degree of automation, and inability to improve work efficiency, so as to improve efficiency and quality, high degree of automation, The effect of reducing labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

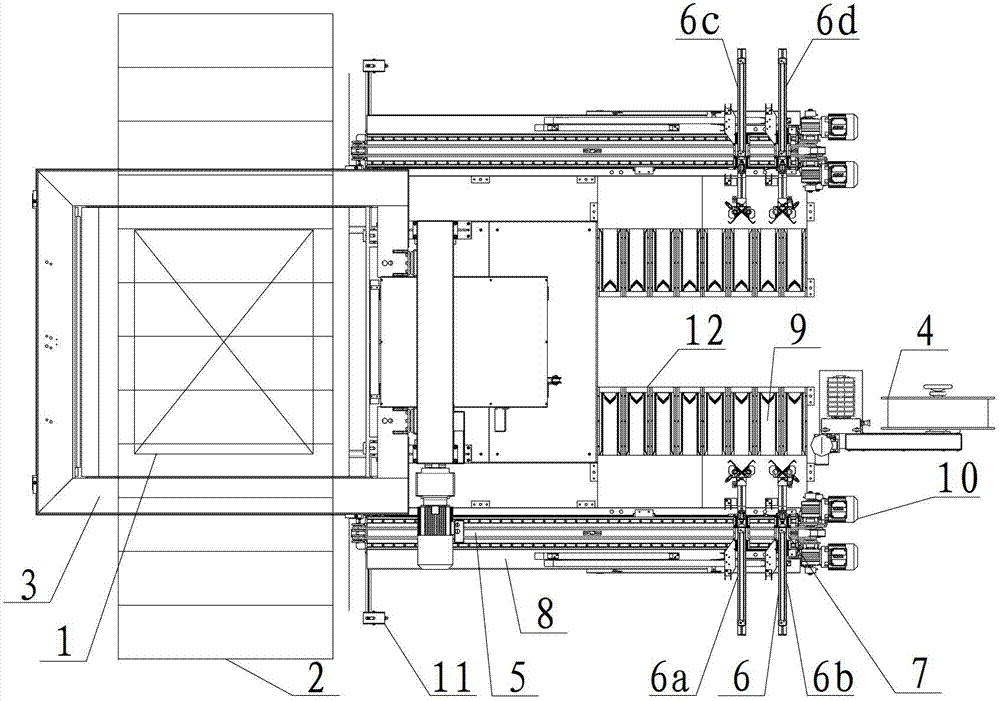

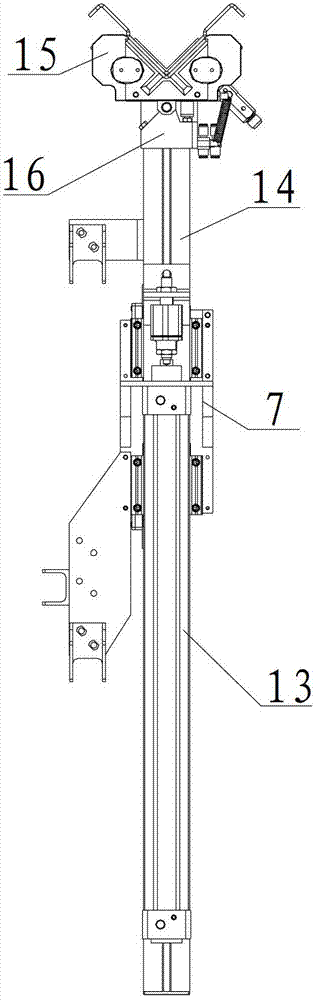

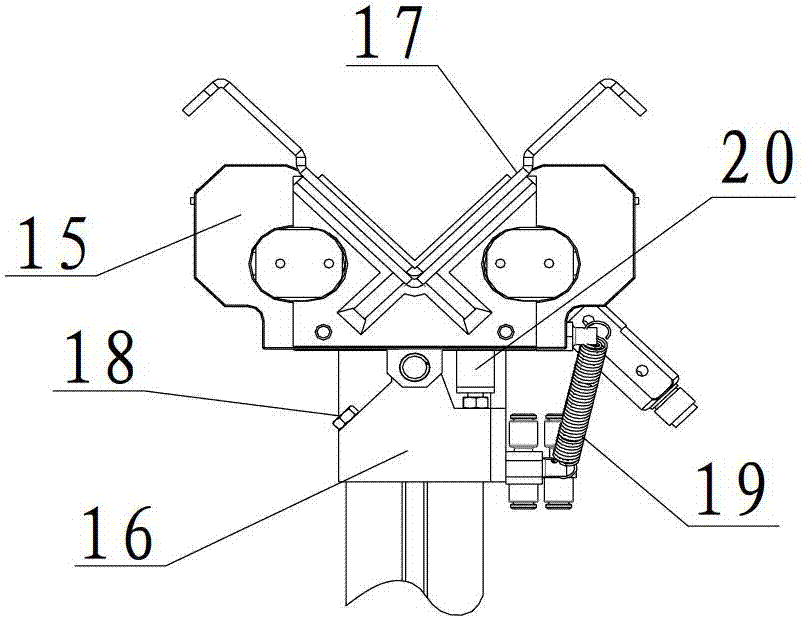

[0025] Such as figure 1 As shown, a packing machine with automatic corner protection includes a conveying mechanism 2 for conveying objects to be packaged 1 , a tightening mechanism 3 and a belt feeding mechanism 4 for binding objects to be packaged 1 . Both sides of the tightening mechanism 3 are respectively provided with guide rails 5 perpendicular to the conveying mechanism 2, and a base 8 carrying the guide rail 5 is provided. On the guide rail 5, each guide rail 5 is equipped with two corner protection mechanisms 6. According to the position of the corner protection mechanism 6, the corner protection mechanism 9 can be divided into a left front protection mechanism 6a and a left rear protection mechanism 6b. , right front add angle protection mechanism 6c and right back add angle protection mechanism 6d, one end of guide rail 5 is provided with driving device 10, for each guide rail, driving device 10 comprises the first that drives guide rail 5 to slide along base 8 top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com